Preflight run-in the fan – Great Planes Phazer EDF ARF - GPMA1802 User Manual

Page 19

19

❏

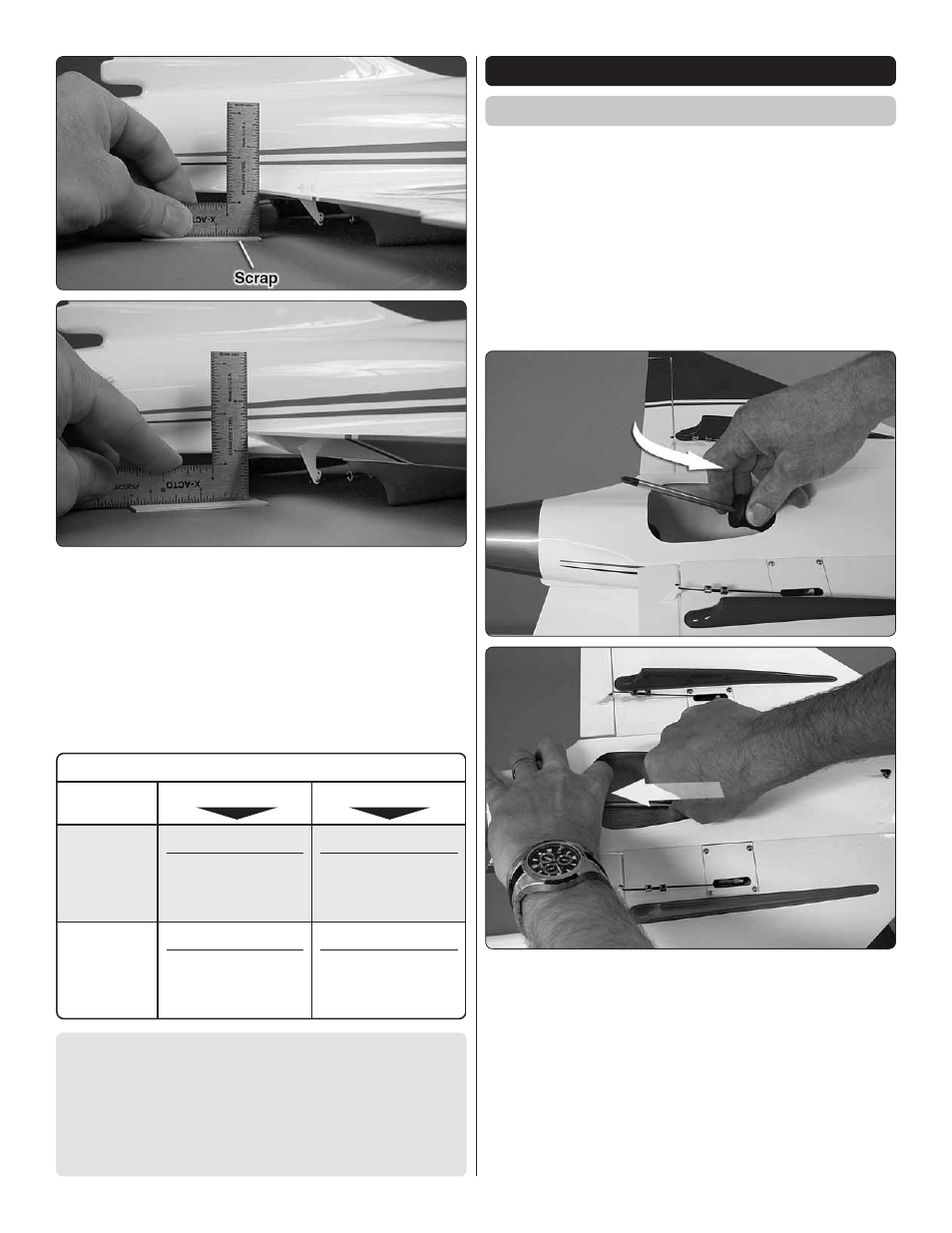

4. Now set the elevator and aileron throws according to the

measurements below: (Hint: If necessary, use a scrap sheet

of balsa or cardstock to shim up your ruler, making it easier

to read the measurements.)

If your radio does not have dual rates, we recommend setting

the throws at the high rate settings.

NOTE: The throws are measured at the widest part of the

elevons (at the root end next to the fuselage).

These are the recommended control surface throws:

ELEVATOR

LOW RATE

AILERONS

HIGH RATE

3/16"

[5mm]

9°

Up

1/8"

[3mm]

6°

Up

3/8"

[10mm]

17°

Up

3/16"

[5mm]

9°

Up

3/16"

[5mm]

9°

Down

1/8"

[3mm]

6°

Down

3/8"

[10mm]

17°

Down

3/16"

[5mm]

9°

Down

IMPORTANT!: When giving an elevator command from

the control stick it is imperative that the defl ection of both

elevons is precisely identical to each other. Otherwise, the

Phazer may yaw toward or away from the ground in banked

turns, not to mention rolling out of loops. Spend time and

use your critical eye to make sure both elevons defl ect the

same when an elevator input is given.

PREFLIGHT

Run-In the Fan

If possible perform this procedure outdoors. In any case, wear

eye and hearing protection and request that any observers

leave the room.

Follow the preparation and break-in procedures on the back

page of the HyperFlow instruction manual for running-in your

fan. Sometimes these HyperFlow fan units can emit a little

resonance while transitioning through the rpm range, which is

OK, but it must run smoothly at full-throttle. If the fan doesn’t

run smooth at full-throttle or if the resonance is more than you

are willing to tolerate, follow the procedure to balance the fan:

❏

1. Disconnect the battery from the ESC. Insert a #2 Phillips

screwdriver into the cheater hole opening and into the fan cone.

Hold the fan with one fi nger while turning the screwdriver to

loosen the screw just enough to rotate the cone.

❏

2. Using the dimple you made on the fan cone as an

alignment cue, rotate the cone so the dimple aligns with the

next fan blade over. Tighten the Phillips screw, connect the

battery, then run up the fan again to see if it smooths out.

Continue the procedure, rotating the cone one blade at a time

until you can get it to run smoothly. If you cannot get the fan

to run smoothly, proceed to the next step.