Gpmz0026e – Great Planes Ammo 36mm Power System - GPMG5240-5325 User Manual

Page 5

Once the pinion gear is in position on the motor shaft, apply

a drop of Great Planes Threadlocker (GPMR6060) to the

threads of the set screw and tighten it down on the flat of

the motor shaft.

REMOVAL OF THE PINION GEAR

The best method of removing the pinion gear is by heating

it with a micro torch and using a pinion puller to carefully

pull the gear off.

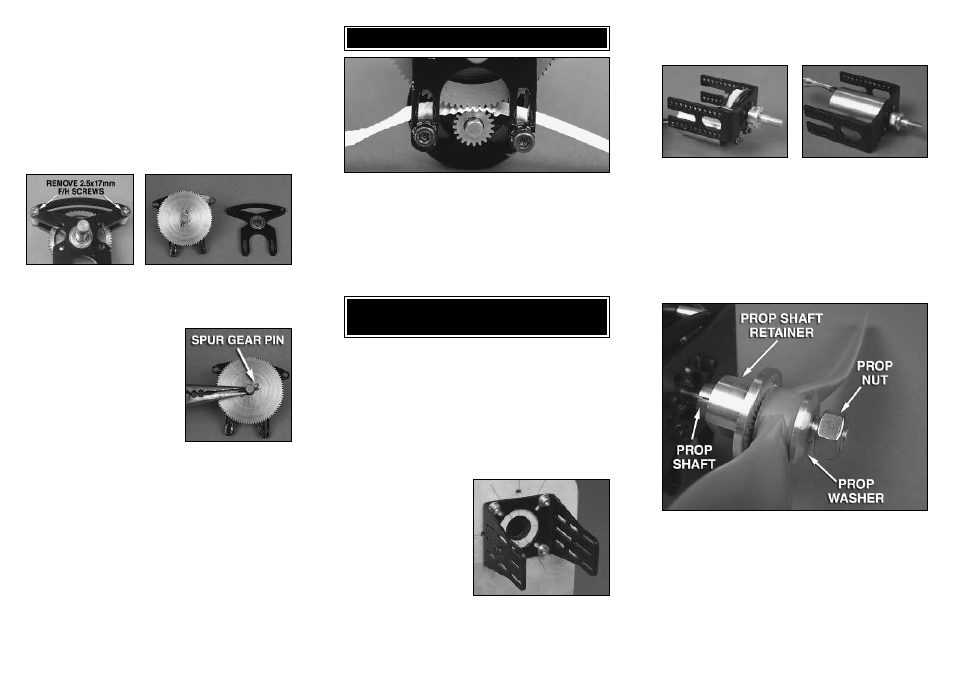

REPLACING THE SPUR GEAR

To remove the spur gear, loosen and remove the two

2.5x17mm flat head machine screws and 5.5mm aluminum

spacers.Remove the backplate, being careful to not lose

the 6mm bearing spacer.

Press the output shaft out of the

spur gear and remove the spur

gear pin. The spur gear can now

be replaced. Reverse the order to

reassemble the gear drive. Be

sure to use a drop of threadlocker

on the two 2.5x17mm flat head

machine screws to prevent them

from loosening during operation.

70/14 =

5:1

70/20 = 3.5:1

90/14 = 6.42:1

90/20 = 4.5:1

MOUNT THE MOTOR TO THE GEAR DRIVE

Loosely mount the motor to the back of the back plate with

two 3x23mm SHC screws and two 3mm flat washers. Place

a piece of notebook paper between the pinion gear and the

spur gear. Squeeze the two gears together while tightening

the two 3x23mm SHC screws. Remove the piece of paper

and the gear mesh should be set. Rotate the gears to make

sure they rotate smoothly. If they do not, slightly loosen the

SHC screws and adjust the gear mesh until the gears do

rotate smoothly.

MOUNT THE BRUSHLESS

LARGE MOTOR MOUNT

In the center of the header card you will find the mounting

hole pattern template for the Brushless Large Motor Mount.

The Motor Mount has the same bolt mounting pattern as

the Great Planes .40-.70 and .60-1.20 Nylon Engine

Mounts. If you are replacing a glow engine with an electric

motor system, remove the nylon engine mount and replace

it with the Large Motor Mount using the same bolts to

attach it to the firewall. If the firewall has not been drilled for

an engine mount and blind nuts, use the mounting template

on the header card to locate the mounting holes.

Attach the Backplate to the

firewall using four 6-32

machine screws and four

#6 flat washers when

replacing the .40-.70 nylon

mount; or four 8-32

machine screws and four

#8 flat washers when

replacing the .60-1.20

nylon mount. Note that if

you are using a gear drive

you may have to cut a hole in the firewall for the motor. The

motor and gear drive can be mounted to the Front Plate

using the 3x8mm machine screws. If you are using a gear

drive other than the Great Planes gear drive, the hole

locations may need to be modified. Also, if you are mounting

the motor to a firewall, longer screws may be required.

In-runner motors that will be run direct drive or gear drive

and are mounted inside the front plate.

Install the prop adapter on the motor shaft or gear drive

output shaft. The Brushless 36mm Gear Drive uses a 6mm

prop adapter (GPMQ4968 Collet Type or GPMQ4942 Set

Screw Type). The Ammo 36mm motors direct drive uses the

5mm prop adapter (GPMQ4966 Collet Type or GPMQ4939

Set Screw Type).

COLLET TYPE PROP ADAPTER INSTALLATION

Slide the prop shaft over the output shaft of the gear drive or

motor. Next slide the prop shaft retainer over the prop shaft.

Note that the hole through the retainer is tapered. Make sure

that the side with the larger diameter hole is installed first.

Install the spinner backplate (if used, not included), the

prop, prop washer and then the prop nut. Tighten the prop

nut against the prop. This will cause the tapered hole in the

prop shaft retainer to squeeze the prop shaft around the

output shaft. Carefully pull on the prop to make sure it is

securely attached to the output shaft of the gear drive.