Carrier INDUCED COMBUSTION 58YAV User Manual

Page 7

through the sight glass or window on the blower access door. The

control indicates status with the LED on continuously, rapid

flashing, or a code composed of 2 digits. (The first digit is the

number of short flashes, the second is the number of longs flashes.)

For an explanation of status codes, refer to service label (See Fig.

8) located on blower access door or the Troubleshooting Guide.

The control stores 1 status code (the last status code to occur) for

a period of 48 hr or until the 115- or 24-v power is interrupted.

NOTE:

Look into blower access door sight glass for current LED

status BEFORE removing the blower access door. Removing

blower access door will open blower access door switch and

terminate 115-v power to control, and status code will be erased.

1. To retrieve status code, proceed with the following:

NOTE:

NO thermostat signal shall be present at control, and all

blower off delays must be completed.

a. Leave 115-v power to furnace turned on.

b. Look into blower access door sight glass for current LED

status.

NOTE:

Leave blower access panel installed to maintain power to

control to view current LED status.

c. Remove control access door.

d. BRIEFLY remove either wire from the main limit switch

until LED goes out, then reconnect it.

NOTE:

If wire to main limit is disconnected longer than 4 sec,

main blower starts, and retrieval request is ignored.

2. When above items have been completed, the following will

occur:

a. LED flashes a status code 4 times. Record this status code

for further troubleshooting.

b. Inducer motor starts and continues to run the entire

component test.

c. Hot surface ignitor is energized for 15 sec, then de-

energized.

d. Main blower operates at heating speed for 10 sec, then

turns off.

e. Main blower operates at cooling speed for 10 sec, then

turns off.

f. Inducer motor stops.

Items a through e above will assist in furnace troubleshooting since

all components are functionally operated except the gas valve. This

procedure is also referred to as

″

Component Test.

″

3. Operate furnace through 1 heat cycle to test for proper

operation and check LED status.

4. If furnace is operating properly and LED indicates proper

operation, replace control access door.

5. Component Test can also be initiated by performing the

following:

a. Remove control access door.

b. Remove blower access door.

c. Manually close blower access door switch.

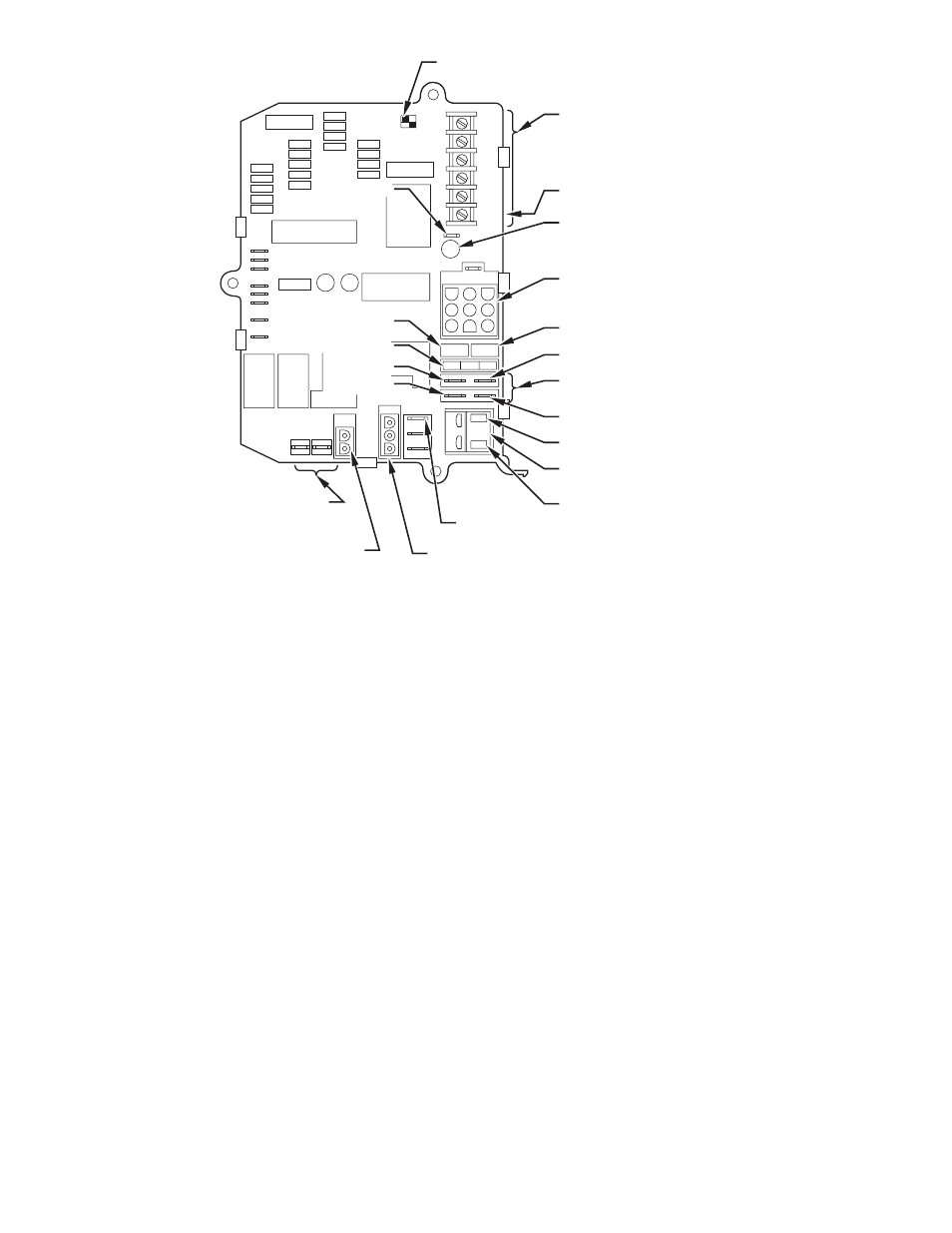

Fig. 7—Furnace Control

A00292

G

R

Y

W

Com

24V

HUM

3-AMP FUSE

HUMIDIFIER TERMINAL

(24-VAC 0.5 AMP MAX)

LED OPERATION &

DIAGNOSTIC LIGHT

HARNESS CONNECTOR

24-V TRANSFORMER SEC-2

SPARE-1

SPARE-2

EAC-1 (BLACK)

EAC-ELECTRONIC AIR CLEANER

TERMINALS (115-VAC 1 AMP MAX)

EAC-2 (WHITE)

115-VAC (L2) NEUTRAL

CONNECTION

24-V THERMOSTAT

TERMINALS

BLOWER SPEED

SELECTION TERMINALS

INDUCER MOTOR

CONNECTOR

115-VAC (L1)

POWER SUPPLY

HOT SURFACE

IGNITOR CONNECTOR

HEAT

COOL

BLOWER OFF DELAY

ADJUSTMENT SWITCH

SEC-1

TEST/TWIN

7