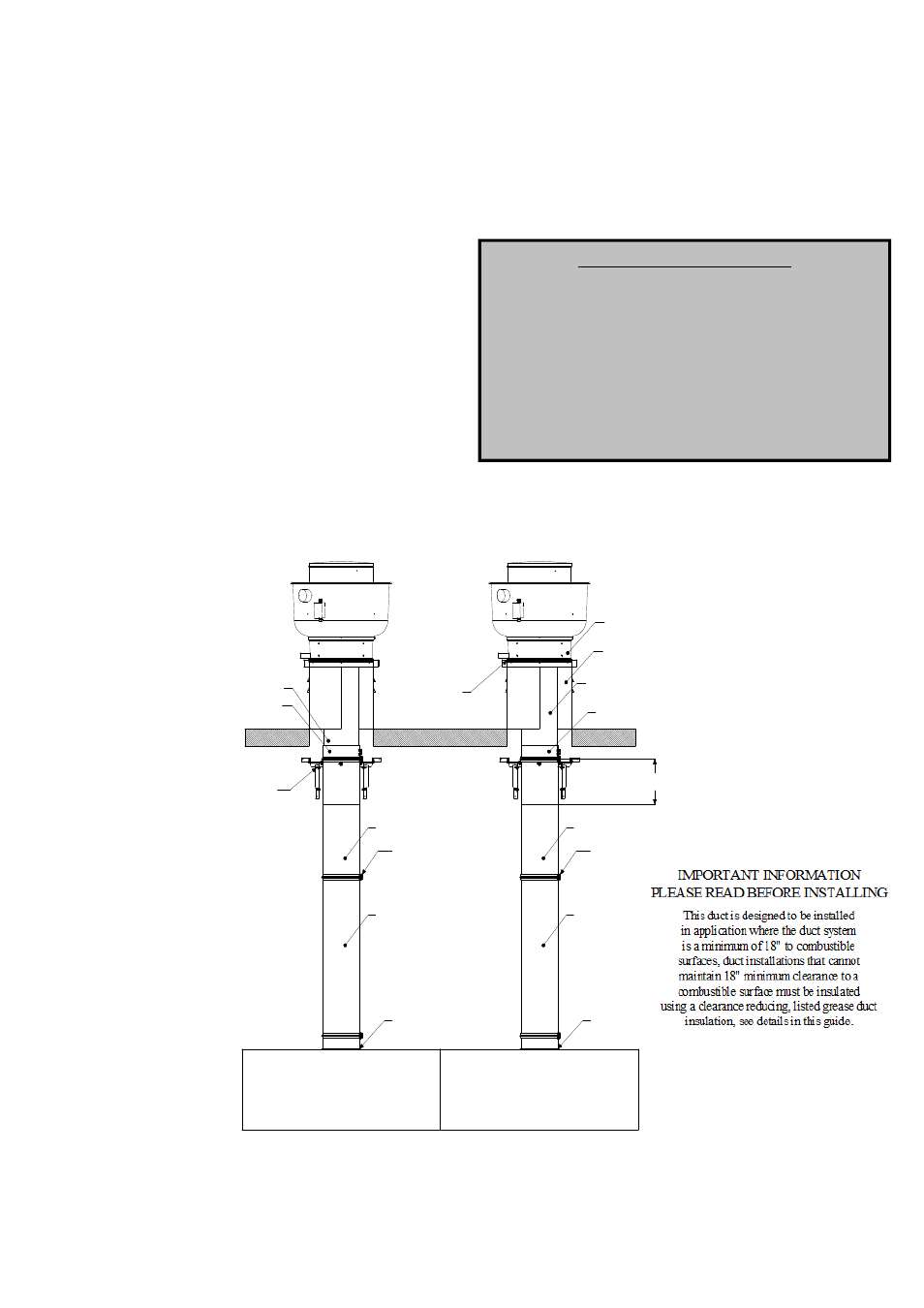

Fig. 12 - grease duct installation guide, Grease duct installation – FloAire Non-Welded Grease Duct Systems User Manual

Page 16

16

Fig. 12 - Grease Duct Installation Guide

Grease Duct Installation:

The illustration shown provides useful information on the

installation of grease duct systems. Each installation is

specific to the application and the job site. When duct

systems are installed outside, welded seams must be

painted with corrosion resistant high temperature paint. If

you encounter a situation not covered by this illustration,

refer to the guide or consult the factory. Remember, if the

distance to a combustible surface is less than 18 INCHES

you will need to wrap the duct in a listed duct wrap to get

“ZERO CLEARANCE TO COMBUSTIBLES”.

Adjustable ducts and standard

ducts can be used to terminate

at the transition plate. The duct

is fully welded to the transition

plate at the factory.

The vertical support assembly is

designed for 2" to 18" clearance

from duct to non-combustable

walls.

Adjustable ducts are used

on runs over 100 ft to compensate

for thermal expansion. The duct will

grow approximately 1" per 100 ft of

duct length for each 100 °F exhaust vapor

temperature above the surrounding air temperature.

The vertical support assembly is

mounted under the "V" clamp and

adjustable collar. This will allow

the vertical movement of the duct

system.

Adjustable duct

Riser

"V" Clamp

Standard duct

Standard duct

Adustable

collar

Fan adapter plate

with ceramic gasket

This duct is designed to be installed

in application where the duct system

is a minimum of 18" to combustible

surfaces, duct installations that can not

maintain 18" minimum clearance to a

combustible surface must be insulated

using a clearance reducing, listed grease duct

insulation, see details in this guide.

IMPOTANT INFORMATION

PLEASE READ BEFORE INSTALLING

"V" Clamp

Riser

Standard duct

Standard duct

See table 2

Adjustable duct

Vented curb per NFPA-96

Adustable

collar

Exhaust fan