Fan adapter plate, Alignment & bracing of grease duct – FloAire Non-Welded Grease Duct Systems User Manual

Page 11

11

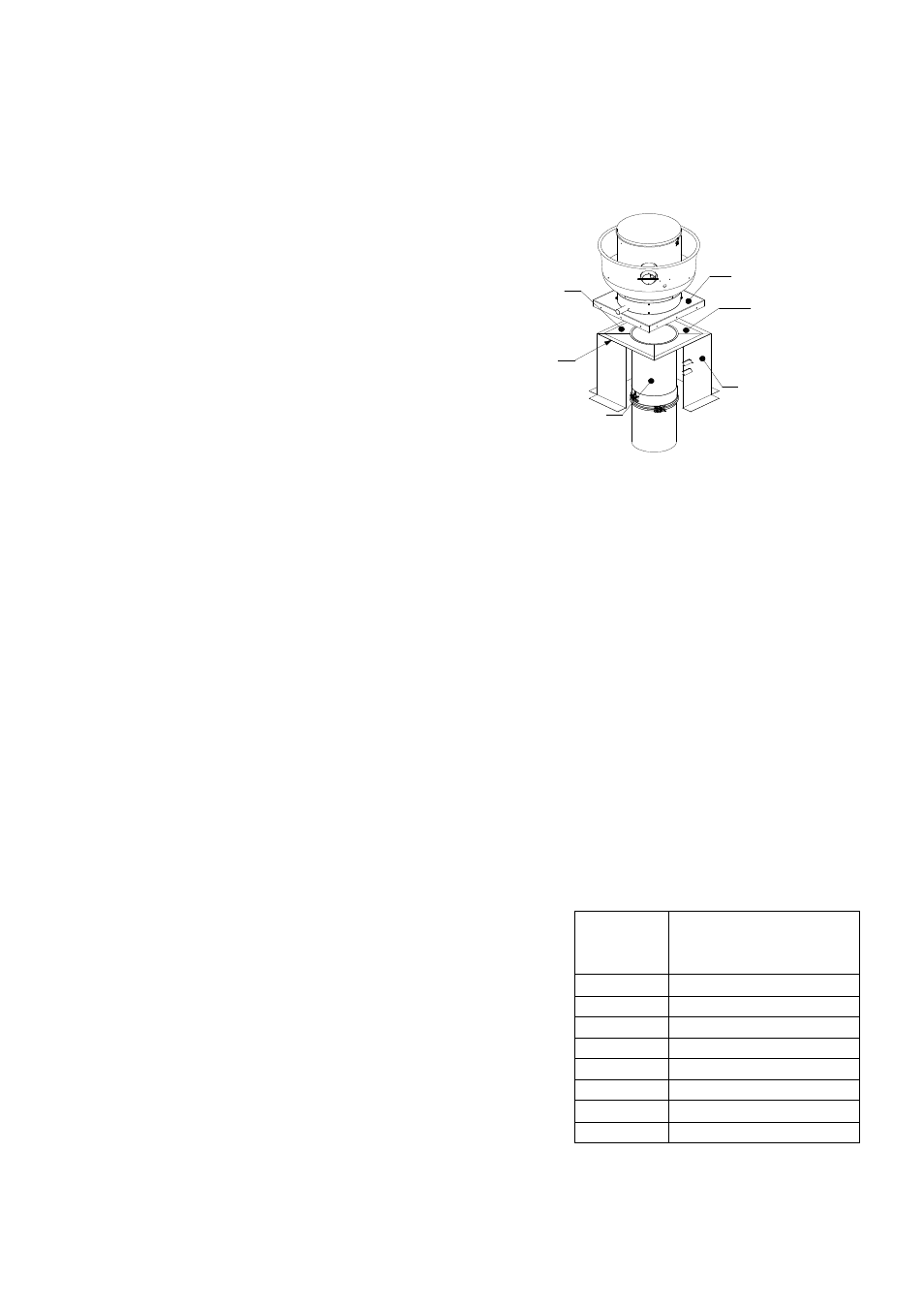

Fan Adapter Plate

The fan adapter plate (Transition Plate) is designed to

connect to a roof curb. The duct section is welded to

the underside of the adapter plate. The adapter plate

is formed to provide a slope to allow grease deposits

to flow back towards the duct. When connected, see

Fig. 7, the plate mounts on top of the fan curb, which

supports the fan housing. The plate may be

positioned off center within the curb provided that the

minimum distance to combustibles is maintained. In

the event that the plate is positioned off center, trim

off excess plate material to allow for fan placement.

Secure the plate to the curb using a minimum of three

fasteners per side. A suitably sized fastener provided

by others is used. The fan adapter plate can be used

to maintain distance to combustibles and also for

vertical support.

Prevention of Grease Accumulation in Horizontal Grease Duct

Duct systems serving Type 1 hoods shall be constructed and installed so that grease cannot collect in any

portion of the duct system. The duct system shall slope not less than ¼” per linear foot towards the hood or

toward an approved grease collection reservoir. Where horizontal ducts exceed 75 feet in length, the slope

shall not be less than 1” per linear foot. Offset collars have been designed to meet the above specification.

The collar is used in conjunction with other accessories such as tee’s and elbows to maintain the above

listed slope in horizontal duct runs. The “V” clamp hardware should be located on the top side of the duct and

be orientated between the 3 and 9 o’clock position on the duct. Never install the “V” clamp with the hardware

orientated on the bottom side of the duct on horizontal runs.

Alignment & Bracing of Grease Duct

Grease duct has the characteristics of a continuous stainless steel pipe and it will expand and contract along

its entire length with changes in its temperature. For this reason, conventional methods of attaching guides

and braces to the outer wall of the grease duct cannot be used. Correctly installed support rings, saddles

and wall guide assemblies will serve to keep the duct aligned, provide for adequate resistance to lateral

loads and allow the free axial expansion and contraction movement. A simplified rule for duct expansion is

that the axial growth will be approximately 1 inch per 100 feet of pipe length for each 100 degrees Fahrenheit

the exhaust vapor temperature is above the surrounding air temperature.

Horizontal Support & Support Spacing

Horizontal duct runs are supported using either 2 X 2 X 1/8” angle

or Unistrut, horizontal support spacing is shown in Table 3. When

cutting the angle or Unistrut to length there must be a minimum of 2”

on either side of the duct or duct wrap. It’s important that the 3/8”

threaded rod suspending the angle or Unistrut does not rub against

the duct or duct wrap. Once the angle has been cut to length it is

suspended using 3/8” threaded rod (minimum). Appropriate sized

holes are drilled/punched in either end of the angle. The 3/8”

threaded rod is secured to the angle or Unistrut using appropriate

sized hardware, washers are used on the top and bottom before

installing nuts, double nuts are used to make sure bottom nuts do not

come loose, see Fig. 8.

Fig. 7 – Fan Adapter Plate

Table 3 – Horizontal Support Spacing

DIAMETER

HORIZONTAL

SUPPORT SPACING

(FEET)

8"

10'

10"

10'

12"

10'

14"

10'

16"

10'

18"

10'

20"

10'

24"

10'

Adapter plate

Ceramic

gasket

(Optional)

Adjustable duct

Exhaust fan

Secured to

curb by others

Vented curb