Air balancing – FloAire FAV-M User Manual

Page 24

24

AIR BALANCING

The Direct-Fired Gas, make-up heater requires the correct air flow velocity across the burner. The burner

profile opening creates a pressure drop which increases the air velocity across the burner. The air flow

switch monitors the pressure difference, and will open the burner circuit if pressure difference is not

correct. The air flow switches have low and high pressure settings. The pressure drop should not be

near the minimum and maximum of the air flow switch. Balancing may be required to fine tune the burner

profile pressure drop. The air flow pressure drop should be checked in fresh and return air modes on the

re-circulating heaters. See the specifications and instructions below on air balancing a re-circulating

heater.

Unit Type

Air Flow

Switch

Part Number

Low

Setting

In. W.C.

High

Setting

In. W.C.

Target Pressure

Drop In. W.C.

Natural Gas

Target Pressure

Drop In. W.C.

Propane Gas

Re-circulating

DDP-106-256

0.15”

0.95”

0.45” – 0.65”

0.45” – 0.65”

The pressure drop should be checked with the burner off or operating at 70 degree discharge if ambient <

65 degrees. Read the pressure drop at the extra probes supplied with the blower ON. This should be

repeated in fresh and return air modes.

WARNING!!

Disconnect power and close all gas valves before and while making burner profile adjustments.

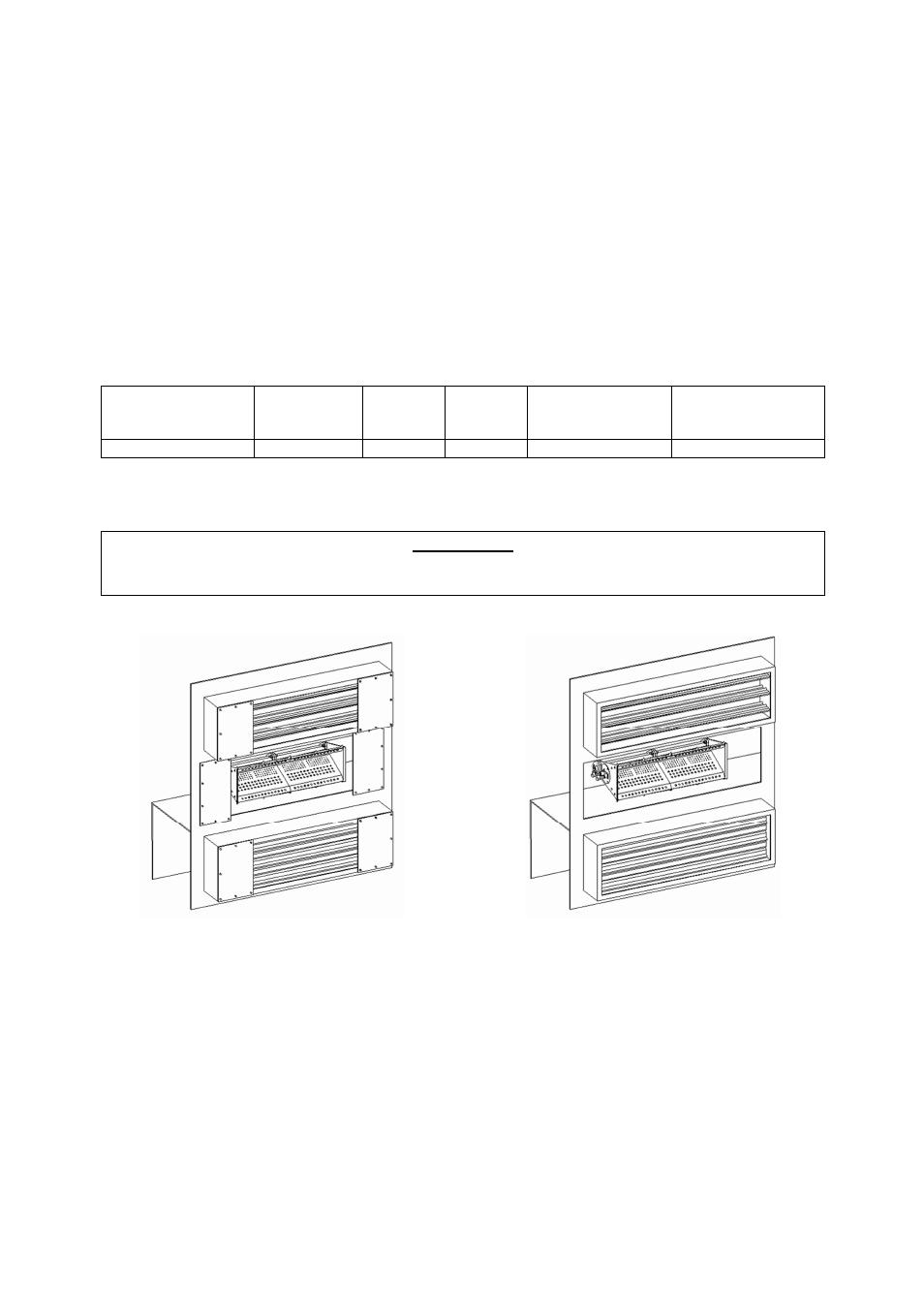

The heaters profile and damper openings are

sized to the units designed airflow. While

balancing the unit to jobsite static pressures the

profile and damper blank-off plates may need to

be moved to achieve the correct air flow

pressure drop.

If the pressure drop is too high, in fresh and

return air mode, remove or adjust the bypass

fresh air and return air damper blank-off panels,

which will decrease the pressure drop. If the

correct air flow pressure drop is still not

achieved adjust the blower drives to decrease

the blowers RPM.