FloAire FAV-M User Manual

Page 19

19

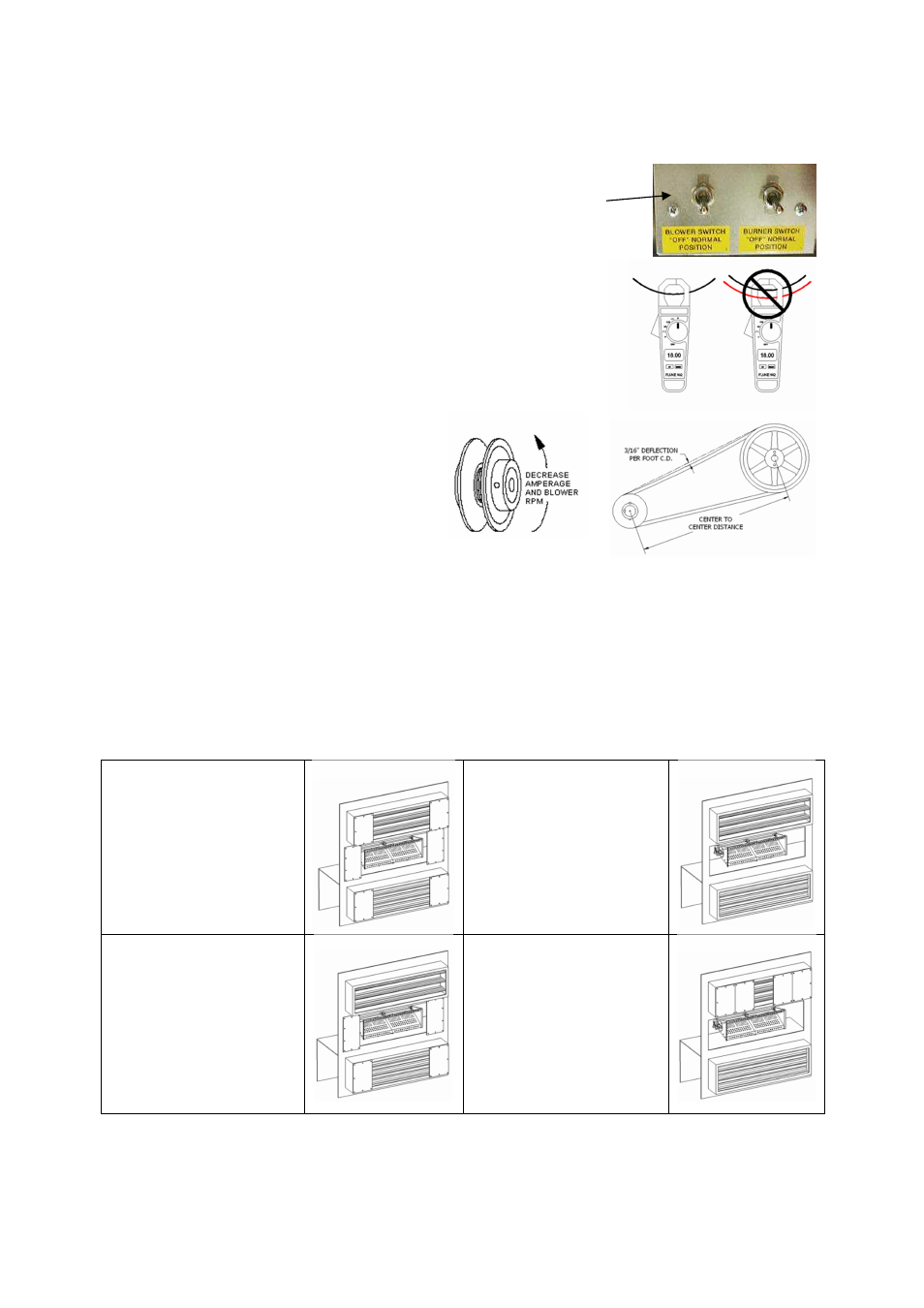

Turn the blower service switch ON. The

(optional) intake or discharge damper

motor will start to open. Once the damper

is 70% open the damper motor internal end

switch will close and energize the blower

motor starter.

Check that the motor amp draw is less than

the FLA (full load amps) of the blower

motor.

The fan RPM may need to be reduced

to decrease motor amps.

Opening the driver pulley decreases

RPM and motor amps.

Closing the driver pulley increases

RPM and motor amps.

Record the motor amps on the Start-

Up Sheet.

If the RPM was adjusted in the field use a

tachometer to record the new RPM on the

Start-Up Sheet.

Check the belt tension after any RPM

adjustments. See the belt tension detail.

Check the air flow pressure drop in 100% fresh air and re-circulating mode. Use the re-circulating

damper motor control to switch the unit between modes.

The damper is controlled by one of the following control options;

Manual Switch – Potentiometer - Photohelic

This will ensure proper pressure drop across the burner profile.

The air flow switch on the re-circulating units is a low and high air flow switch and opens below

0.15 in w.c and above 0.95 in w.c.

The target pressure drop range for the re-circulating unit is 0.40 – 0.60 in w.c. Both 100% fresh air

and re-circulating mode should be within this range.

Use the profile plates or blower RPM to increase or decrease the pressure drop.

Record the pressure drops on the Start-Up Sheet.

If the pressure drop is too low, in

fresh and return air mode, add

more blank-off panels to the

burner profile opening and bypass

fresh air and return air damper,

which will increase the pressure

drop. (There must be at least 2

inches of area minimum around

the burner.) If the correct air flow

pressure drop is still not achieved

adjust the blower drives to

increase the blowers RPM.

If the pressure drop is too high, in

fresh and return air mode, remove

or adjust the bypass fresh air and

return air damper blank-off panels,

which will decrease the pressure

drop. If the correct air flow

pressure drop is still not achieved

adjust the blower drives to

decrease the blowers RPM.

If the pressure drop is too high, in

fresh mode only, remove or adjust

the bypass damper blank-off

panels, which will decrease the

pressure drop. The return air

damper opening may need to be

adjusted to maintain the correct air

flow pressure drop when switching

back to return air mode.

If the pressure drop is too high, in

fresh and return air mode, remove

or adjust the bypass fresh air and

return air damper blank-off panels,

which will decrease the pressure

drop. If the correct air flow

pressure drop is still not achieved

adjust the blower drives to

decrease the blowers RPM.

BLOWER

SERVICE

SWITCH