Remote control panel, Power supply wiring, Paint booth applications – FloAire FAV-M User Manual

Page 13

13

9. If necessary, the original wire supplied with the heater may be replaced with type TW wire or the

equivalent.

Remote Control Panel

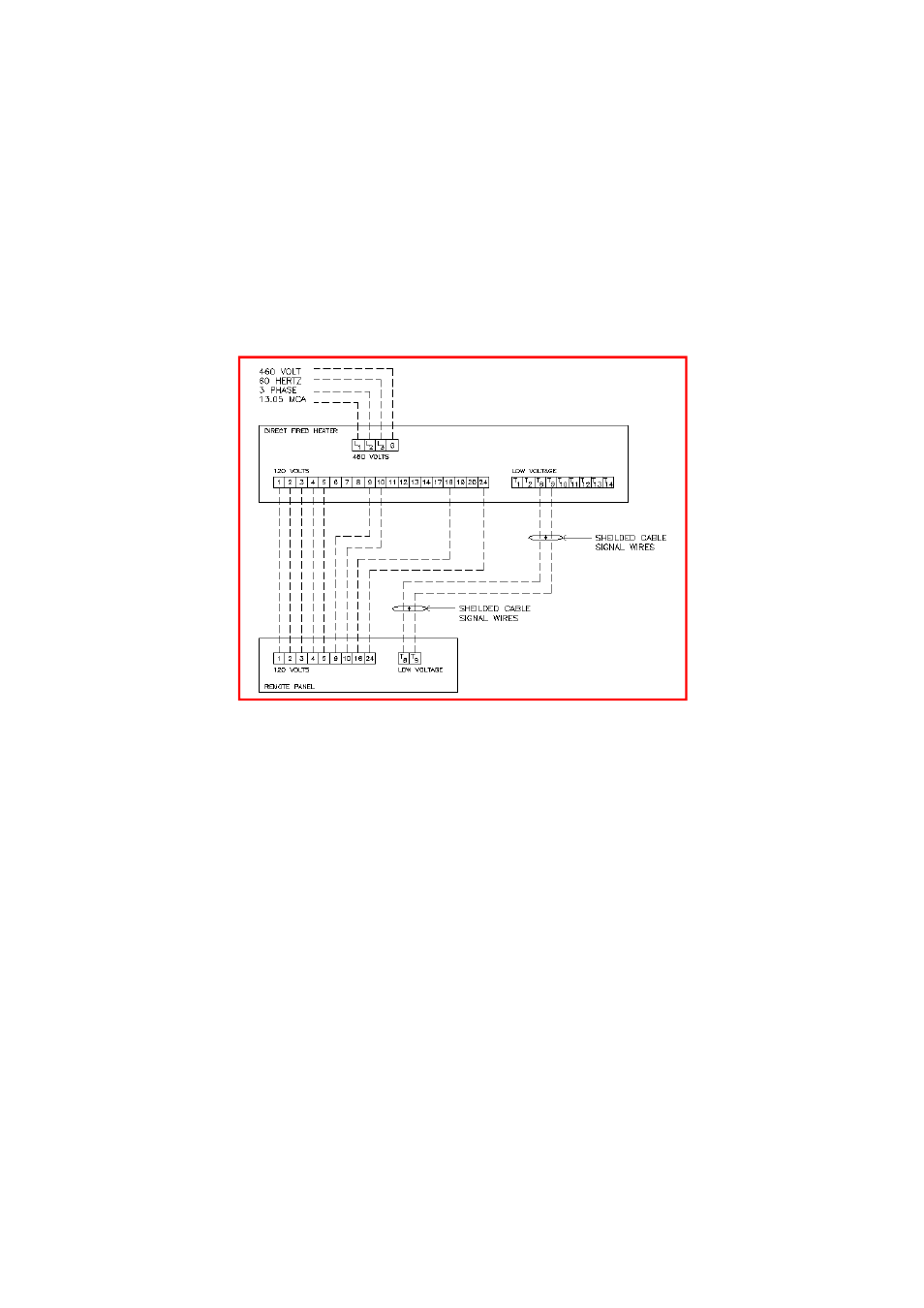

For units with the optional remote control panel, a terminal strip inside the panel matches the terminals in

the heater unit. This diagram shows an example of the field wiring for a unit with a 401M remote panel.

Consult the as built wiring print supplied with the equipment. Most remote panels and VAV applications

have signal wiring which needs to be shielded cable to avoid high voltage interference.

Power Supply Wiring

The units input power supply is listed on the unit nameplate. If the units power supply does not match the

unit nameplate contact the service department for a new wiring print and parts.

Paint Booth Applications

If a low temperature control is not an integral part of the heater, it is recommended that one be installed in

areas where freeze protection is needed in the event of a burner shutdown. The space should be

ventilated following a bake cycle to purge any contaminants and cool product prior to personnel entering

the space. If the unit was supplied with paint booth controls from the factory, refer to the schematic for

installation of the interlock to disable spraying equipment unless the heater is operating in ventilation

mode. Refer to electrical schematic for interlock to disable facility lighting within the process space during

the bake cycle.

If they unit will be operating as a process heater in the re-circulating position with airborne particulate

matter, install means to facilitate inspection, maintenance, cleaning and access to fire protection devices.

In re-circulating process applications, the system shall be designed to provide 200 cfm per 1000 cfh of

natural gas based on the maximum capacity of the heater plus an allowance to sufficiently dilute the

VOC’s created by the process to maintain the lower explosive level below a 25% threshold value.