Fawcett TM Upper - Hyd. Driven User Manual

Page 15

GEROTOR MOTOR

A25

A37

A50

A62

A100

A125

DISPLACEMENT

(cubic inches per revolution)

0.82

1.16

1.53

1.88

3.11

3.73

GEROTOR SIZE (Inches)

0.250

0.375

0.500

0.625

1.000

1.250

CAPACITY (Maximum GPM)

8 8 8 8 8 8

SPEED (Maximum RPM)

2255

1592

1206

982

595

495

TORQUE (Maximum Inch-pounds)

149

222

284

363

570

656

MAXIMUM SIDE LOAD (pounds-force)

300

300

300

300

300

300

MAXIMUM PUSH FORCE (pounds-force)

500

500

500

500

500

500

MAXIMUM PULL FORCE (pounds-force)

300

300

300

300

300

300

Sample

Motor

Weights

(pounds)

F

Standard Flange - Short Shaft

3.55

3.55

3.55

3.60

3.80

3.90

FMO

Standard Flange - Long Shaft

3.65

3.65

3.65

3.70

3.90

4.00

FM

Foot Mount - Long Shaft

6.15

6.15

6.15

6.20

6.40

6.50

F-T

Turned Down Flange - Short Shaft

3.10

3.10

3.10

3.15

3.35

3.45

FMO-T

Turned Down Flange - Long Shaft

3.20

3.20

3.20

3.25

3.45

3.55

FA-A

Aluminum Body & Flange - Short Shaft

2.45

2.45

2.45

2.50

2.70

2.80

FMOA-A

Aluminum Body & Flange - Long Shaft

2.55

2.55

2.55

2.60

2.80

2.90

FA-TA

Aluminum Body & Turned Down

Flange - Short Shaft

2.30

2.30

2.30

2.35

2.55

2.65

FMOA-TA

Aluminum Body & Turned Down

Flange - Long Shaft

2.40

2.40

2.40

2.45

2.65

2.75

The rotor gear of these low-weight motors rolls through four com-

plete "CYCLES" for each revolution of the output shaft. Thus,

four times greater torque at one-fourth of the conventional speed

is obtained without the use of gear reducers. In other words, with

hydraulic motors the same amount of torque is assured as you

would get from a much larger ordinary motor that is considerably

more expensive.

Of considerable importance to application design engineers is the

smooth rotation and long life of these unique motors. Because the

motors have five fluid chambers, the inherent four-to-one ratio

provides twenty fluid power cycles for each revolution of

the

output shaft. This feature assures a distinct addition, these

motors have only three moving parts (motor shaft, spline drive,

gerotor star) - this greatly extends the service life.

Within the broad range of each gerotor, any torque or speed can

be readily secured. Also the various sizes of gerotors available

provide a torque range from 0 to 656 inch-lbs. and R.P.M.

ranging from 0 to 2255. High selectivity to exactly meet

requirements is inherent in these motors.

We recommend parallel circuits versus series circuits, because

the back pressure generated cannot exceed 300 psi.

Recommended Oil: Mobil

®

DTE 13 (ISO-32 Hydraulic Oil).

Please note:

The capacity (GPM),

speed (RPM), and

output torque (IN-LBS)

provided in the table

are maximum quanti-

ties for

speci

? c gerotor

sizes.

For motor operating

characteristics under

various application

requirements - see

"Selection Guide"

tables on pages 4

and 5.

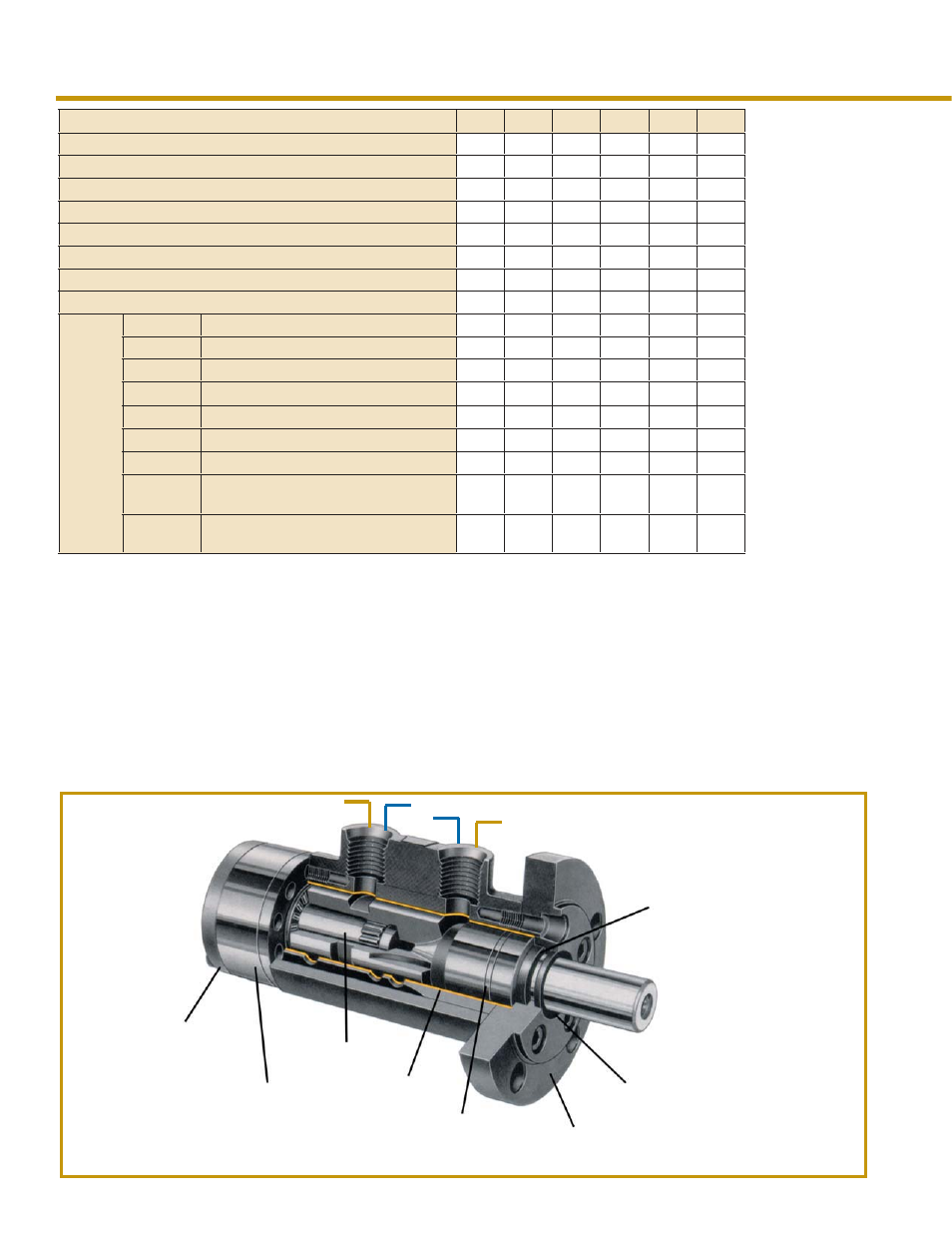

Positive

Metal-to-Metal

Sealing

Matched

Gerotor

Positive

Splined Drive

Lamina-

Bronze

Bearing

Surface

Needle

Bearing

Six Styles of Mounts

(see page 2)

Sealed Against

Contamination

Lip Seal

6

Arrows show how

the shaft will sping

depending on fluid

flow through the

motor.