Selection procedure, 50xp unit suggested rigging, Selection procedure (with example) – Carrier 50XP User Manual

Page 11: Select unit based on required cooling capacity, Select electric heat

11

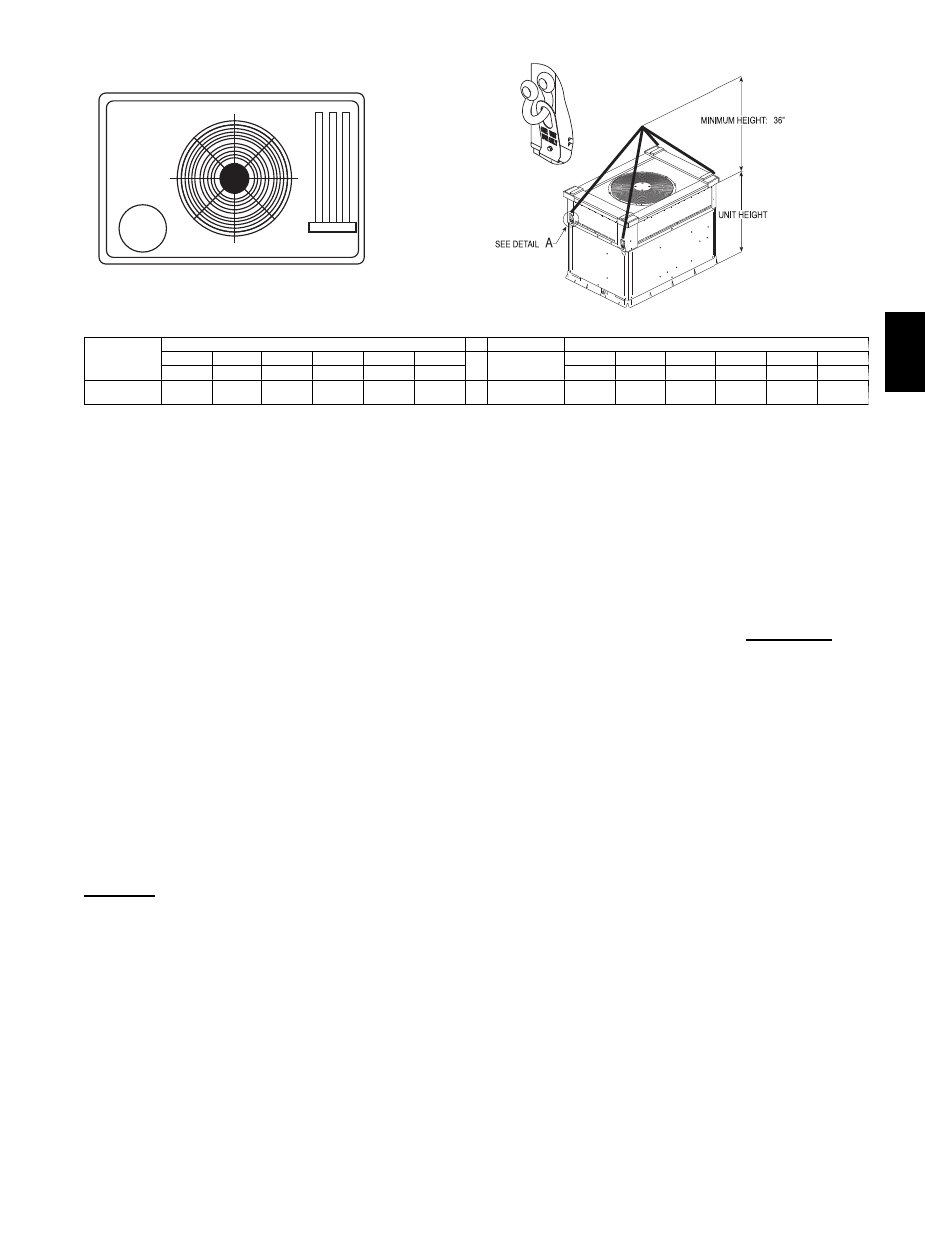

50XP UNIT SUGGESTED RIGGING

1

2

3

4

A07216

DETAIL A

(914 mm)

A08005

Unit*

SMALL CABINET

LARGE CABINET

024

024

030

030

036

036

Unit*

042

042

048

048

060

060

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

Rigging

Weight

345

156

349

158

367

166

Rigging

Weight

425

193

459

208

504

229

NOTE: See dimensional drawing for corner weight distribution. Corner weights shown on drawing are based on unit---only weights and do not include pack-

aging.

SELECTION PROCEDURE (WITH EXAMPLE)

1. Determine cooling and heating requirements at

design conditions:

Given:

Required Cooling Capacity (TC)

34,500 Btuh

. . . . . . . . . .

Sensible Heat Capacity (SHC)

26,000 Btuh

. . . . . . . . . . . .

Required Heating Capacity

15,000 Btuh

. . . . . . . . . . . . . . .

Condenser Entering Air Temperature

95°F(35°C)

. . . . . . . .

Indoor--Air Temperature

80°F (26°C) edb

. . . . . . . . . . . . .

67°F (19°C) ewb

Evaporator Air Quantity

1200 CFM

. . . . . . . . . . . . . . . . . .

External Static Pressure

0.20 IN. W.C.

. . . . . . . . . . . . . . . . .

Electrical Characteristics

230--1--60

. . . . . . . . . . . . . . . . . . .

2. Select unit based on required cooling capacity.

Enter Net Cooling Capacities table at condenser entering

temperature of 95°F (35°C). The 036 unit at 1225 CFM and 67°F

(19°C) ewb (entering wet bulb) will provide a total capacity of

36,500 Btuh and a SHC of 27,600 Btuh. Calculate SHC correction,

if required, using Note 4 under Cooling Capacities tables.

3. Select electric heat.

The required heating capacity is 15,000 Btuh.

Determine additional electric heat capacity in kW.

15,000 Btuh

= 4.4kW of heat required

3,414 Btuh/kW

Enter the Electric Heater Packages table for 208/240, single--phase,

036 unit. The 5 kW heater at 240v most closely satisfies the

heating required. To calculate kW at the 208v, multiply the heater

kW by multiplication factor 0.75 found in the Wattage

Multiplication Factors table.

5 kW x 0.75 = 3.75 kW

3.75 kW x 3414 = 12,802.50 Btuh

4. Determine fan speed and power requirements at

design conditions.

Before entering the air delivery tables, calculate the total static

pressure required. From the given example, the Filter Pressure

Drop Table, and the Accessory Electric Heat Pressure Drop table,

find:

External Static Pressure

0.200 IN. W.C.

Filter

0.130 IN. W.C.

Wet Coil Pressure Drop

0.032 IN. W.C.

Total Static Pressure

0.362 IN. W.C.

Enter the table for Dry Coil Air Delivery—At 0.362 IN. W.C. ESP

(external static pressure) and NOM speed pin selection, the motor

will deliver 1235 cfm.

5. Select unit that corresponds to power source

available.

The Electrical Data Table shows that the unit is designed to operate

at 208--1--60.

50X

P