Maintenance – EDCO SS-26E User Manual

Page 11

E-SS2636-DGE-I-1012

Printed in USA

TVW

©2012

Page 11

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com • Email: [email protected]

The following maintenance instructions are brief explanations

of some of the items suggested in the Maintenance Schedule chart on page 12.

These instructions are not replacements for the

Engine Manufacturer’s Maintenance Instructions.

Maintenance

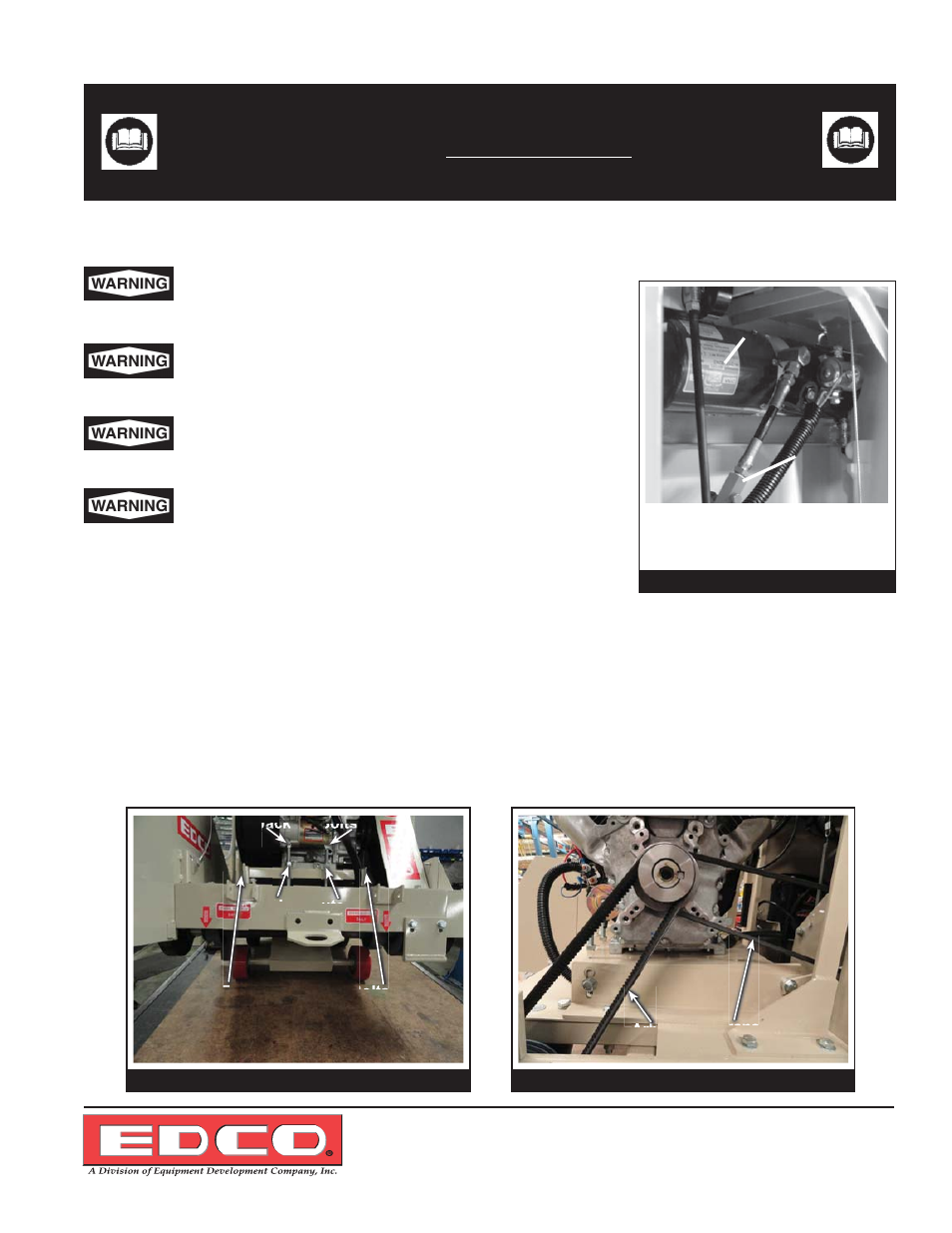

Inspect Arbor Drive Belts - SS26-E, SS26-31D & SS36-57D

•

Proper belt tension must be maintained to transmit the engine power to the cutting blade. Slipping belts will over

heat, the blade life will be shortened and the cutting speed limited. Over tensioned belts will shorten belt and

bearing life. 70 ft. lbs. of defl ection at the center between the pulley’s, is recommended.

•

On new machines and after installation of new belts, adjust belt tension after the fi rst four hours or sooner, then

tension as necessary.

•

Loosen engine mount mounting bolts and jam nuts, then turn jacking bolts to lift or lower engine mount. Lift engine

to tighten belts lower engine to loosen/replace belts. (Figure 10)

Disconnect the machine from the power source by

disconnecting the spark plug or battery leads before

performing any maintenance.

Remove all rings, watches and jewelry prior to working

anywhere around the DC Hydraulic power unit.

(Figure 9 & Review Figure 3,4,5 & 5A)

Use extreme caution not to damage the hydraulic unit. Fluid

under pressure can pierce the skin and enter the blood stream

causing death or serious injury.

NOTE: Failure to keep arbor shaft drive belts properly tensioned

can cause engine crank shaft bearing failure and void engine

warranty. Use a belt tensioning gauge to properly tension arbor

shaft drive belts .

DC Hydraulic

Power Unit

This view shows DC Power Unit

where it is mounted inside machine

above the access door.

Figure 9

Hydraulic Fluid

Flow Controls

(see Figure 17)

Figure 11

Arbor

Belts

Transmission

Belt

Figure 10

Jacking Bolts

Jam Nuts

Engine Mounting Bolts