Before starting the engine: *gasoline models only – EDCO CPM-10 User Manual

Page 6

E-CPL8-CPM-4-8-10-I-0112

Printed in USA

©2012

TVW

Page 6

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

When using Hi-carbon steel or Tungsten Carbide cutter wheels:

IMPORTANT!

Read the engine manufacturer’s manual, familiarize yourself with engine start procedures.

3. Check level of oil in engine crankcase (engines are usually shipped dry, oil must

be added as per engine manufacturers instructions).

*

4. Check fuel level ( follow engine manufacturers instructions).

*

5. Be sure all guards (belt, motor, cutter wheel) are in place and secure.

6. Vacuum hose port should have hose attached or cap installed to control dust

generated during the cutting operation.

7. Locate engine on/off switch, if the engine is so equipped. On some engines the

throttle control is also the engine shut-off switch. Familiarize yourself with this

operation. *

8. All

EDCO gasoline engine operated planers are equipped with a STOP switch,

usually located on the handle. Use this switch for emergency engine shut-off.

*

9. Cold engine starting: Be sure fuel line valve is open. Set choke (separate lever

on some engines - others have choke as part of throttle control). Open throttle

(full to engage choke) 3/4 to full on engines with a separate choke. Turn engine

ignition switch ON. Be sure emergency STOP switch is ON.

*

10. Before starting determine that the recoil starter assembly turns freely, starter

rope pulls easily and the rope retracts properly.

*

BEFORE STARTING THE ENGINE: *Gasoline models only

Be sure that the cutter drum assembly has been properly installed and the cutter

drum shaft is in place and secured.

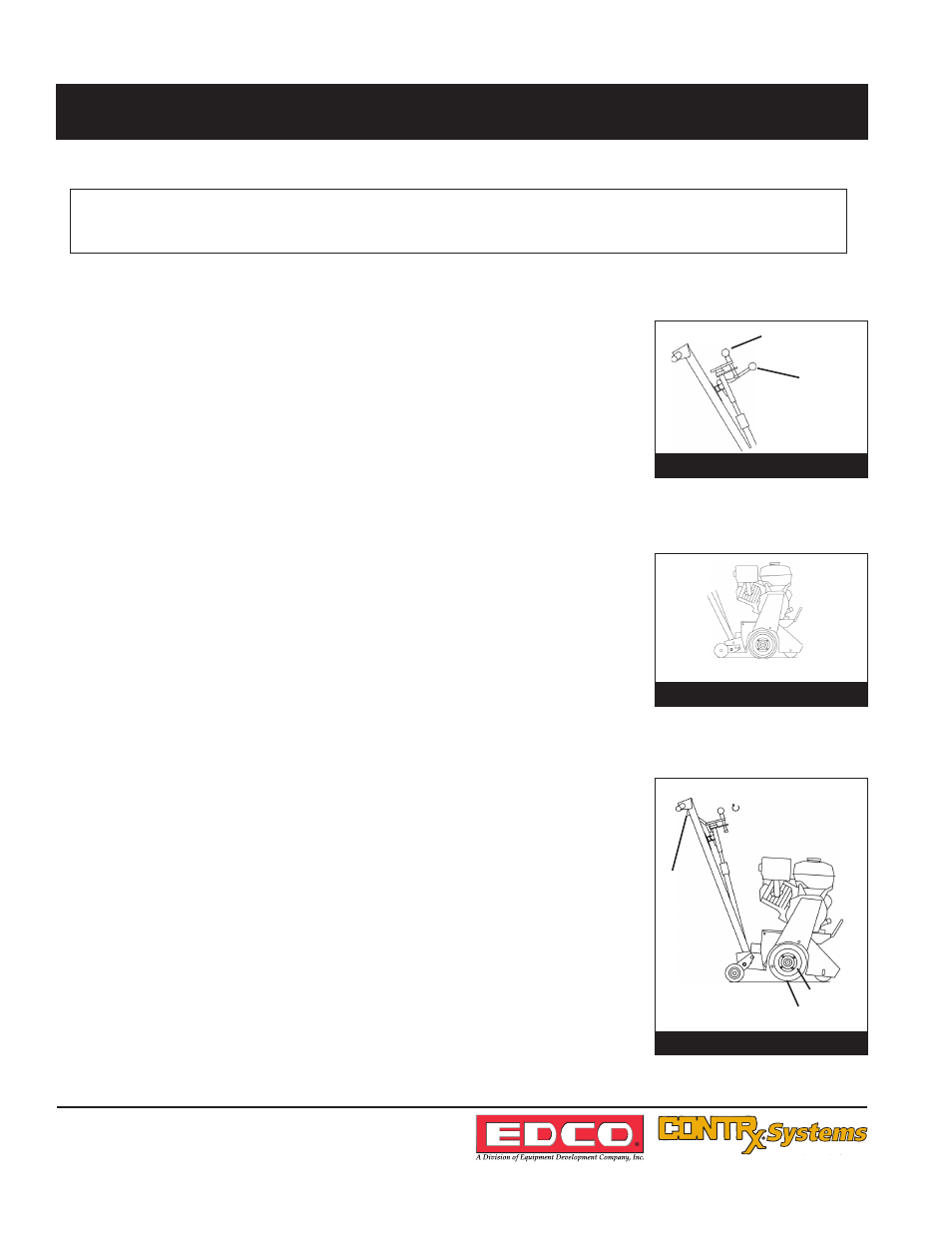

1. Select a level place at the job site. Set the “disengage lever” in the full DOWN

position. Refer to (Figure A).

It is most important to determine the position of the cutter wheels as they relate to

the slab or floor surface. If the drum assembly is filled with cutters, the cutter

wheels will most likely contact the slab when the “disengage lever” is lowered.

Refer to (Figure B).

Turn the “depth adjustment crank” UP until the cutter wheels are clear of the slab.

Refer to (Figure A). Follow these instructions each time before the engine is

started to prevent accidental damage to the slab.

2. Raise the “disengage lever” to the full UP position. DO NOT force the lever. If

resistance is felt, turn the “depth adjustment crank” DOWN one or two turns.

This will allow the “disengage lever” to reach its normal full UP position. Refer to

(Figure C).

CPM-4-8-10-SACRALITE8 OPERATING INSTRUCTIONS

Figure B

Cutter Wheels Contacting Slab Surface

Figure A

Depth Adjustment Crank

Disengage Lever

Full DOWN

Position

Figure C

Cutters Clear of Slab

Surface

Cutter Drum

Cutter Wheel

Disengage

Lever

UP

Position

Depth Adjustment Crank

UP