For your safety and well being dry grinding, Dry grinding – EDCO CPM-10 User Manual

Page 13

E-CPL8-CPM-4-8-10-I-0112

Printed in USA

TVW

©2012

Page 13

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

FOR YOUR SAFETY AND WELL BEING

DRY GRINDING

DO NOT operate gasoline/propane

powered equipment without adequate

ventilation. Carbon monoxide is an

invisible, oderless gas that can kill.

Dry Grinding:

Dry Grinding creates a large volume of airborne dust. For health reasons, the

operator should wear an applicable respirator. The dust may contain chemicals

known to cause serious illnesses, including Silicosis a fatal disease of the lungs.

Check the chemical properties of the material to be removed and follow all

EPA/OSHA regulations.

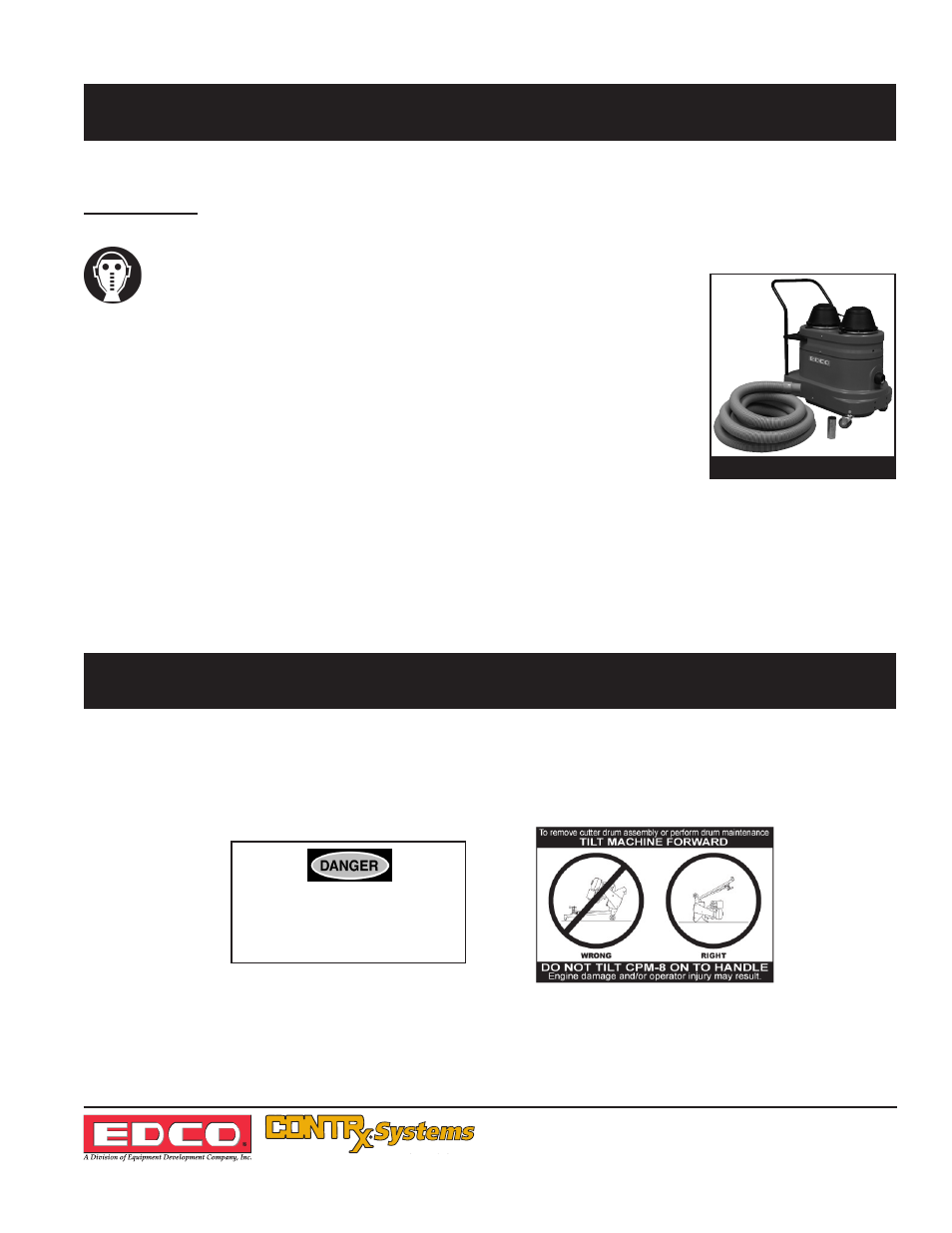

• An Industrial vacuum, capable of handling high volume of fine dust, such as the VAC-

200 (Figure 5), should be used when dry grinding with this machine. If the material

being used is hazardous or contains Silica - the vacuum unit should be capable of

removing Respirable Silica and hazardous particles of less than 3 microns and if

necessary, have the capability to be equipped with a HEPA filter.

• Most standard drum type units use a paper bag filter. The dust created during

grinding is extremely fine and will clog the filter bag of these units and eventually

damage the vacuums motor. In addition, damage to the CPM-4-8-10 engine could

occur.

• The collected debris and filters should be disposed of according to procedures that

comply with current EPA/OSHA standards.

Vac-200

Figure 5