Eagle Microsystems RA1000 User Manual

Page 13

13

TROUBLE:

Inability to zero.

PROBABLE CAUSE:

1.

Residual present in sample.

CORRECTIVE ACTION: 1.

Use de-chlorinated water.

TROUBLE:

Improper reagent feed.

PROBABLE CAUSE:

1.

Faulty starwheel.

CORRECTIVE ACTION: 1.

See OPERATION, Section B.

TROUBLE:

Excessive reagent feed.

PROBABLE CAUSE:

1.

Striker motor rotation reversed.

3.

At shutdown, starwheel aligned for constant

reagent feed.

CORRECTIVE ACTION: 1.

Motor must turn counterclockwise, (top view).

Inspect motor leads for proper connection.

2.

Jog motor to reposition starwheel.

TROUBLE:

Insufficient reagent feed.

PROBABLE CAUSE:

1.

Starwheel plugged.

2.

Blockage in feed line to the starwheel.

CORRECTIVE ACTION: 1.

Clean. See OPERATION, Section B.

2.

Check per OPERATION, Section B.

TROUBLE:

Display blank.

PROBABLE CAUSE:

1.

Power OFF.

2.

Bad connector or incorrect wiring to control

unit.

CORRECTIVE ACTION: 1.

Turn power switch ON or connect power.

2.

Check for proper plug connections or repair /

replace LCD display module.

C.

INSTRUMENT SETTINGS

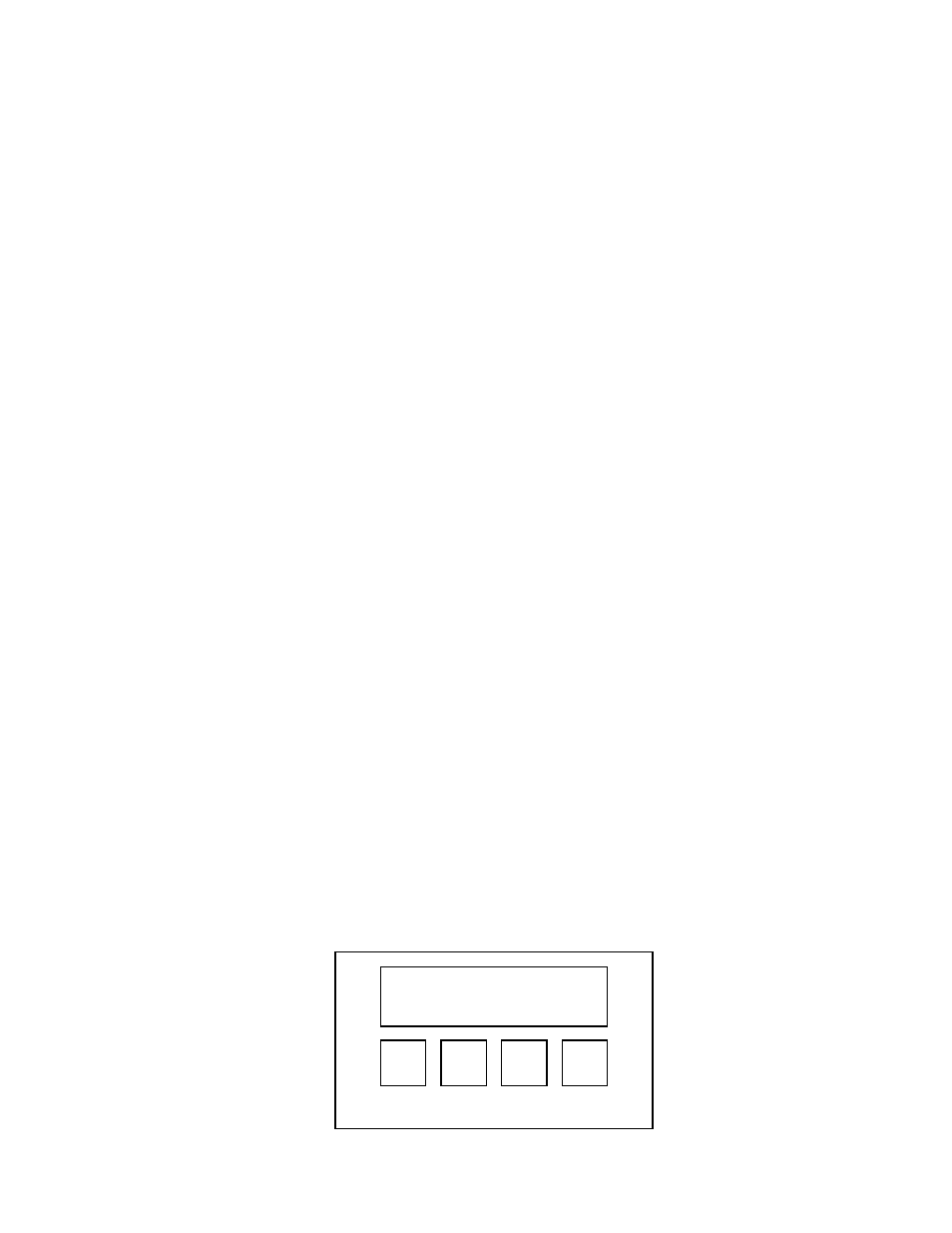

The top line of the LCD display is formatted to show a selected value along with its

engineering units, and the second line normally provides function labels for the four pushbuttons

located below the display. The pushbuttons do not have any labels, so for the purpose of this

document, the pushbuttons will be assigned numbers 1 through 4.

2

Line1: Value & units

Line 2: Pushbutton legend

1

3

4