Build the fuselage build the ailerons – Dynaflite DYFA3030 User Manual

Page 16

16

❏ ❏

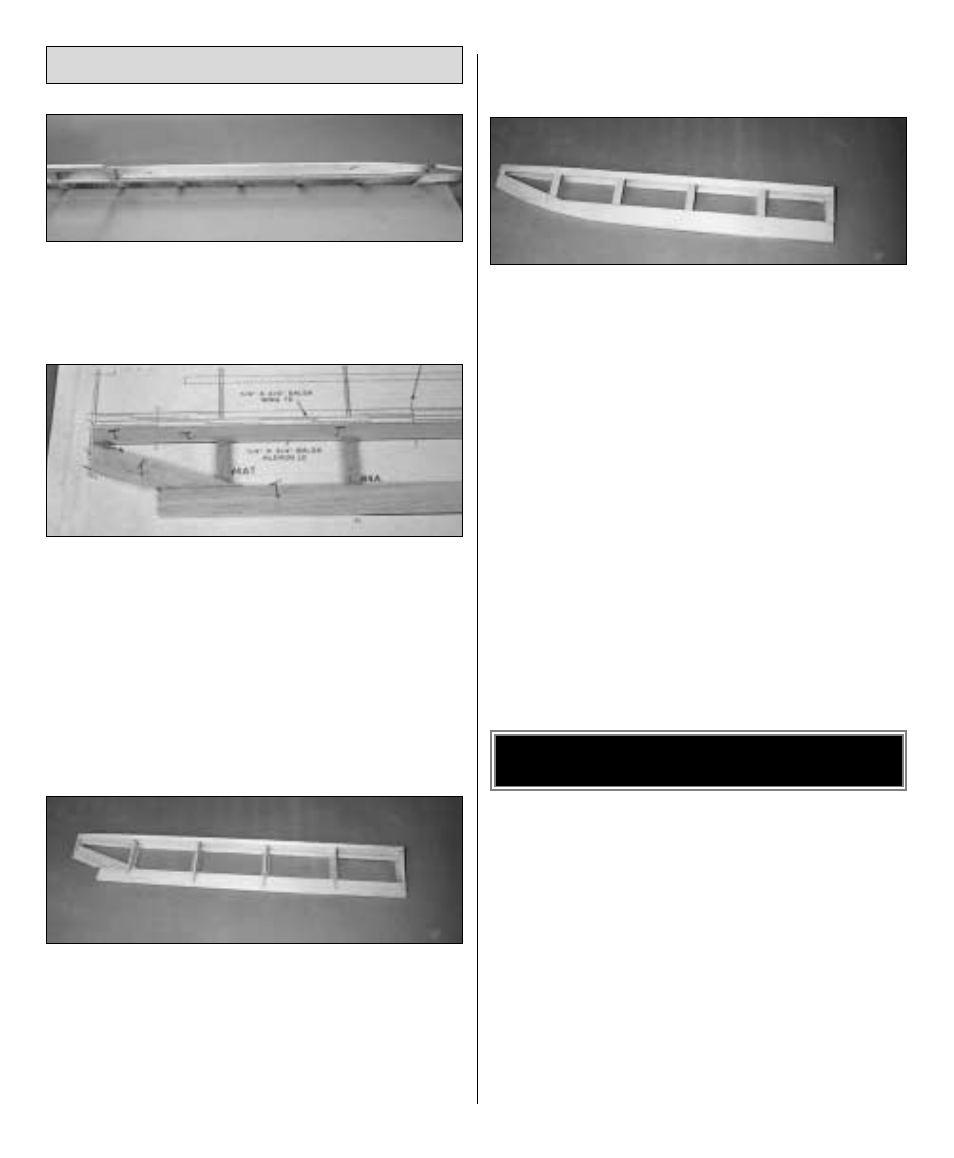

1. Shape the LE of the aileron from a 1/4" x

3/4" x 24" balsa stick using the TE of the wing as a

guide. Shape the aileron LE to the shape of the TE of

the wing without the 3/32" sheeting on it.

❏ ❏ ❏ ❏

2. Cut the aileron LE sheeting from a

piece of 3/32" x 1/2" x 24" balsa. Do the same with

the TE from the remainder of the piece of 3/32" x

15/16" x 36". Pin and glue these pieces together over

the plan. Using the leftover pieces of cap strip from the

wing, fit and glue cap strips in place on the aileron.

This is a good time to build the other 3 aileron

frames using the same steps.

❏ ❏

3. Glue the LE piece you made in step one on

the frame work. You will have to unpin the tip end of

the frame work and glue it up against the LE. Glue

the ribs in position on the cap strips.

NOTE

: Rib W5A is too small to die-cut to the correct

length. Cut it to length before gluing it in position.

❏ ❏

4. Fit and glue the hinge blocks in place using

leftover 1/4" x 3/4" balsa.

❏ ❏

5. Glue the frame made in step 2, to the

top of the aileron, aligning the TE of the frames to

each other.

❏ ❏

6. Remove the aileron from the plan.

❏ ❏

7. Sand the assembly to the airfoil shown in

the cross section on the plan.

❏

8. Build the other aileron by repeating steps 3-7.

NOTE

: Before beginning construction of the fuselage

you should determine where you will mount the servos.

There are cutouts for mounting the servos in the

fuselage bottom deck and the rear of the fuselage

sides. If you are installing a gas engine you should

mount the servos in the rear of the fuselage to improve

the balance. The cutouts in the bottom deck can be

used if you are installing a lighter 2-stroke or 4-stroke

engine. Punch out the locations you plan to use and

glue the other cutouts that you will not use into place.

❏

1. Place the fuselage plan on your building board

and cover it with wax paper.

BUILD THE FUSELAGE

BUILD THE AILERONS