Dynaflite DYFA3030 User Manual

Page 15

15

❏

6. Use two 21" x 4" pieces of paper to roll into

paper tubes. Slip these into the holes in the wing ribs

to form a conduit for the servo wires.

❏ ❏

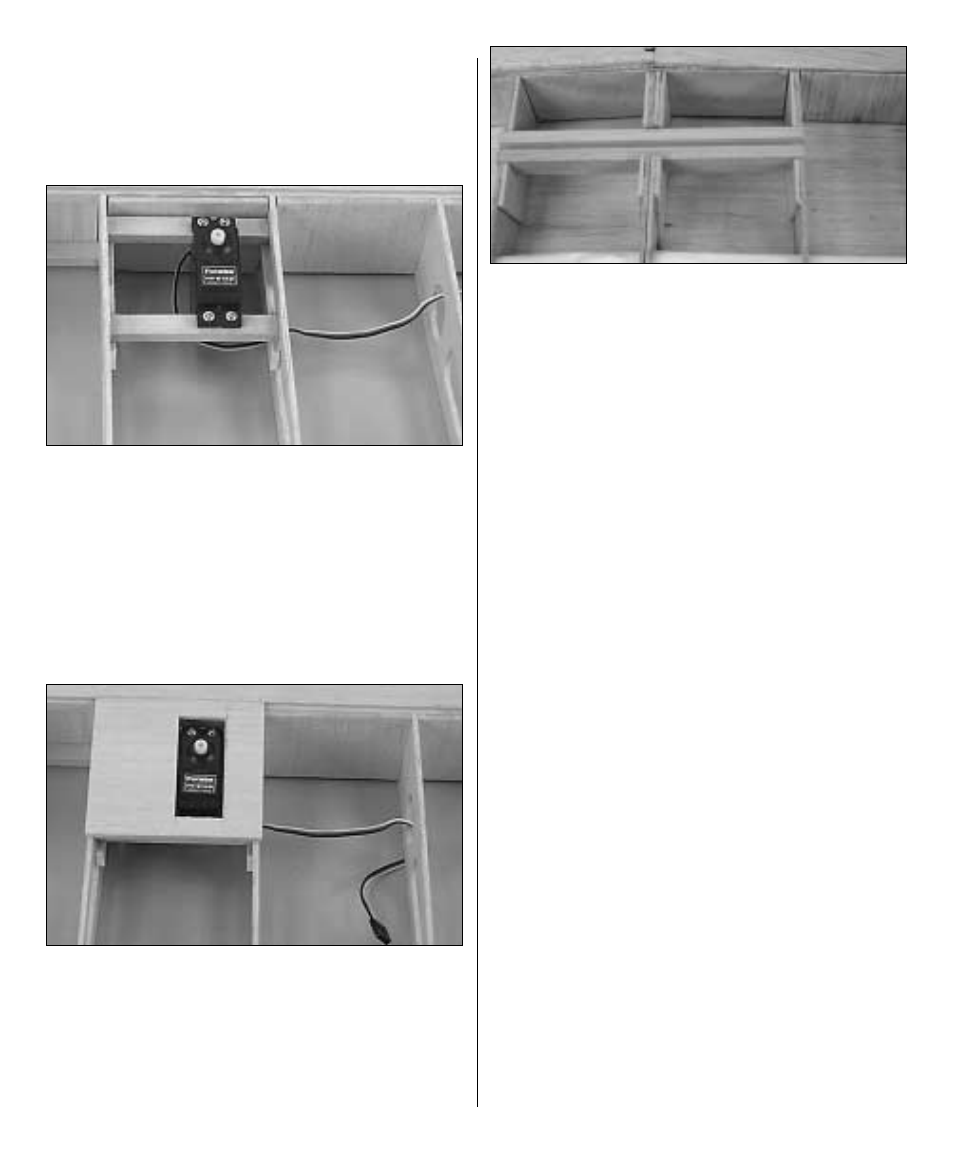

7. Make two 2-3/4" long servo rail supports

from the die-cut 1/8" x 1/2" x 11" ply strips. Make

two 3-5/8" long servo rails from a 1/4" x 3/8" x

36" basswood stick. Glue the rails and supports

where shown on the plan with the rails spaced as

needed to fit your servo. Mount the servo to the rails

with the screws included with your servo.

❏ ❏

8. Sheet the area around the servo using

leftover 3/32" balsa so the covering has something

to adhere to. Support the sheeting on the bottom

with strips of 3/32" balsa.

Repeat the above two steps for the second wing

half.

❏

9. Glue the hardwood landing gear block into

place with 6-minute epoxy.

❏

10. Cut 1/8" holes through the top wing sheeting

from the bottom side, directly above the servo lead

tubes. From the top of the wing enlarge the holes in

the sheeting to 1/2" diameter centering the holes

above the paper tubes. Cut matching 1/2" holes in

the servo lead tubes.

❏

11. Use a 3/32" x 3" x 24" balsa sheet to cut, fit

and glue the center sheeting between ribs W1 and the

first W3 on both wing halves. Cut a 3/4" wide strip in

the sheeting above the landing gear block from the

root rib to the end of the landing gear block.

❏

12. Using the 3/4" strip, as well as leftover

3/32" sheeting, cut and glue filler strips to the

landing gear block so that the strips will be level with

the center sheeting. Cut a grove in these strips for the

3/16" landing gear wire.

❏

13. From the 3/32" x 3/8" x 30" balsa sticks,

cut, fit and glue the cap strips to the tops of ribs W3

to W6 and the wing tip pieces as you did on the top

of the wing.

❏

14. Sand the LE to the shape shown on plan.

Rough sand the rest of the wing.

❏

15. Reinforce the wing center joint using 3"

fiberglass tape and epoxy. Apply the fiberglass to

the top and bottom of the wing.