D.A.S. Audio SM Series User Manual

Page 17

EN

7

RIGGING

Warning

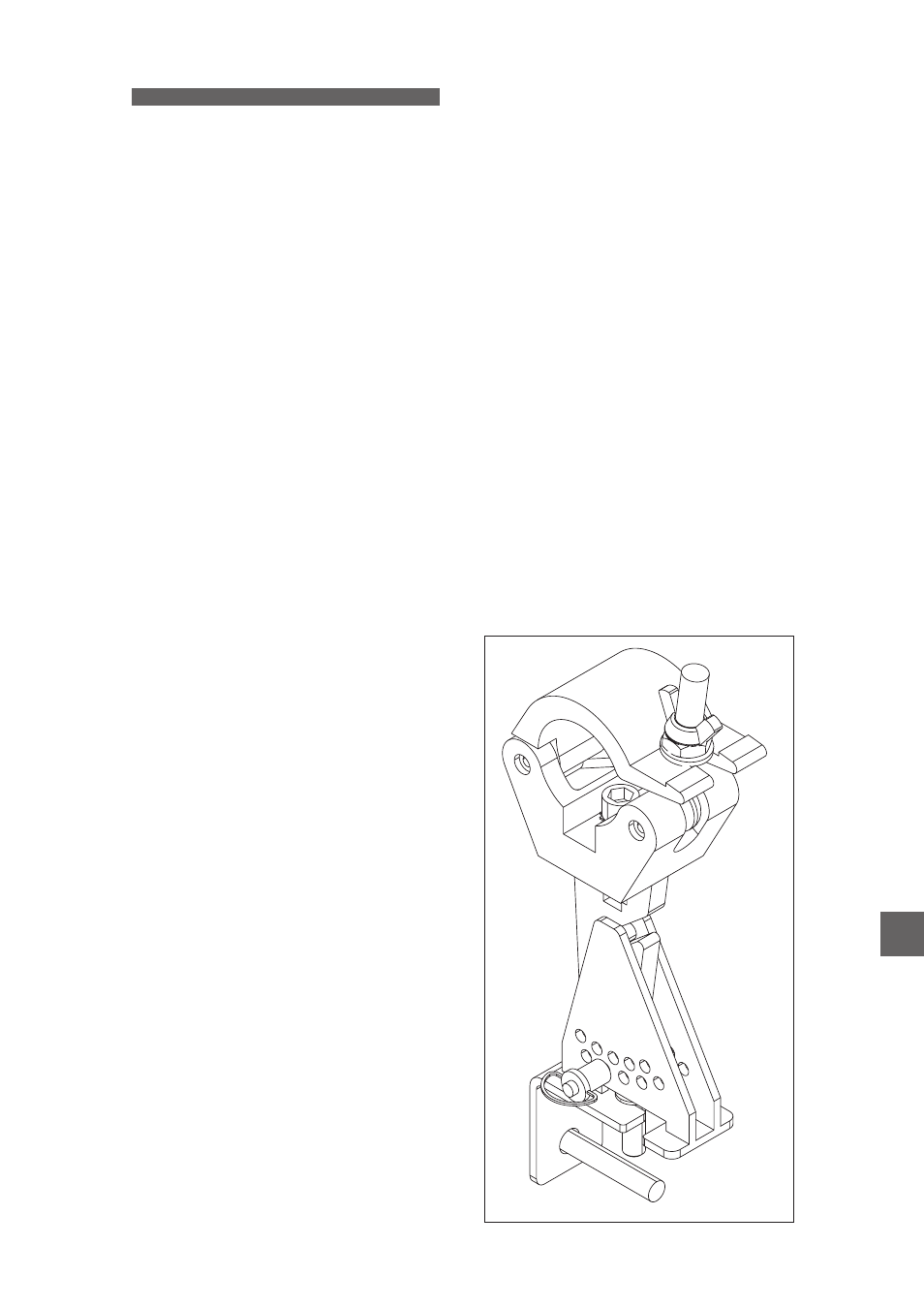

Rigging with

AX-TRUSS

Introduction

Base of the support

AX-TRUSS

Hook clamp

The

rigging hardware has been

designed to fly the cabinets from structure trusses

of 50mm diameter (2 in diameter). The

base must be fixed to the upper rear corner of the

box by means of two M10 screws. The screw

needed to attach the

base to the upper

side of the box is the same that comes with the

box on that position. The screw to be inserted on

the rear side of the box is a special one that is

provided with the

accessory.

allows for several vertical angles from

+10º to -35º. The vertical angle is set up by

inserting a highly resistant quick release pin into

the holes in the

base.

AX-TRUSS

AX-TRUSS

AX-TRUSS

AX-TRUSS

AX-TRUSS

AX-TRUSS

are the models in the

that feature the necessary hardware to be flown.

As has been said above,

are versatile

multipurpose cabinets which can also be used as

a low profile floor monitor.

cabinets feature 6 “L” shaped internal

metal hardware pieces, each one including 2 M10

nuts, thus providing a total of 12 rigging points.

SML

stage monitors series

SML

SML

This manual contains needed information for

flying

DAS

Audio

systems,

description

of

the

elements

and

safety

precautions. To perform any operations related to

flying the system, read the present document first,

and act on the warnings and advice given. The

goal is to the allow the user to become familiar

with the mechanical elements required to fly the

acoustic system, as well as the safety measures to

be taken during set-up and teardown.

Only

experienced

installers

with

adequate

knowledge of the equipment and local safety

regulations should fly speaker boxes. It is the

user's responsibility to ensure that the systems to

be flown (including flying accessories) comply with

state and local regulations.

The working load limits in this manual are the

results of tests by independent laboratories. It is

the user's responsibility to stay within safe limits. It

is the user's responsibility to follow and comply

with safety factors, resistance values, periodical

supervisions and warnings given in this manual.

Product improvement by means of research and

development is ongoing at D.A.S. Specifications

are subject to change without notice.

To this date, there is no international standard

regarding the flying of acoustic systems. However,

it is common practice to apply 5:1 safety factors

for enclosures and static elements. For slings and

elements exposed to material fatigue due to

friction and load variation the following ratios must

be met; 5:1 for steel cable slings, 4:1 for steel

chain slings and 7:1 polyester slings. Thus, an

element with a breaking load limit of 1000 kg may

be statically loaded with 200 kg (5:1 safety factor)

and dynamically loaded with 142 Kg (7:1 safety

factor).

When flying a system, the working load must

be lower than the resistance of each individual

flying point in the enclosure, as well as each box.

Hanging hardware should be regularly inspected

and suspect units replaced if in doubt. This is

important to avoid injury and absolutely no risks

should be taken in this respect. It is highly

recommended that you implement an inspection

and maintenance program on flying elements,

including reports to be filled out by the personnel

that

will

carry

out

the

inspections.

Local

regulations may exist that, in case of accident,

may require you to present evidence of inspection

reports and corrective actions after defects were

found.

stage monitors

Manual del Usuario

/ stage monitors / User’s Manual