Step 2 — rig and mount the unit, Step 3 — complete refrigerant piping connections, Table 2 — weight distribution – Carrier 38AE014 User Manual

Page 6: Table 4a — refrigerant piping sizes — 60 hz, Table 4b — refrigerant piping sizes — 50 hz, Fig. 3 — compressor mounting 6

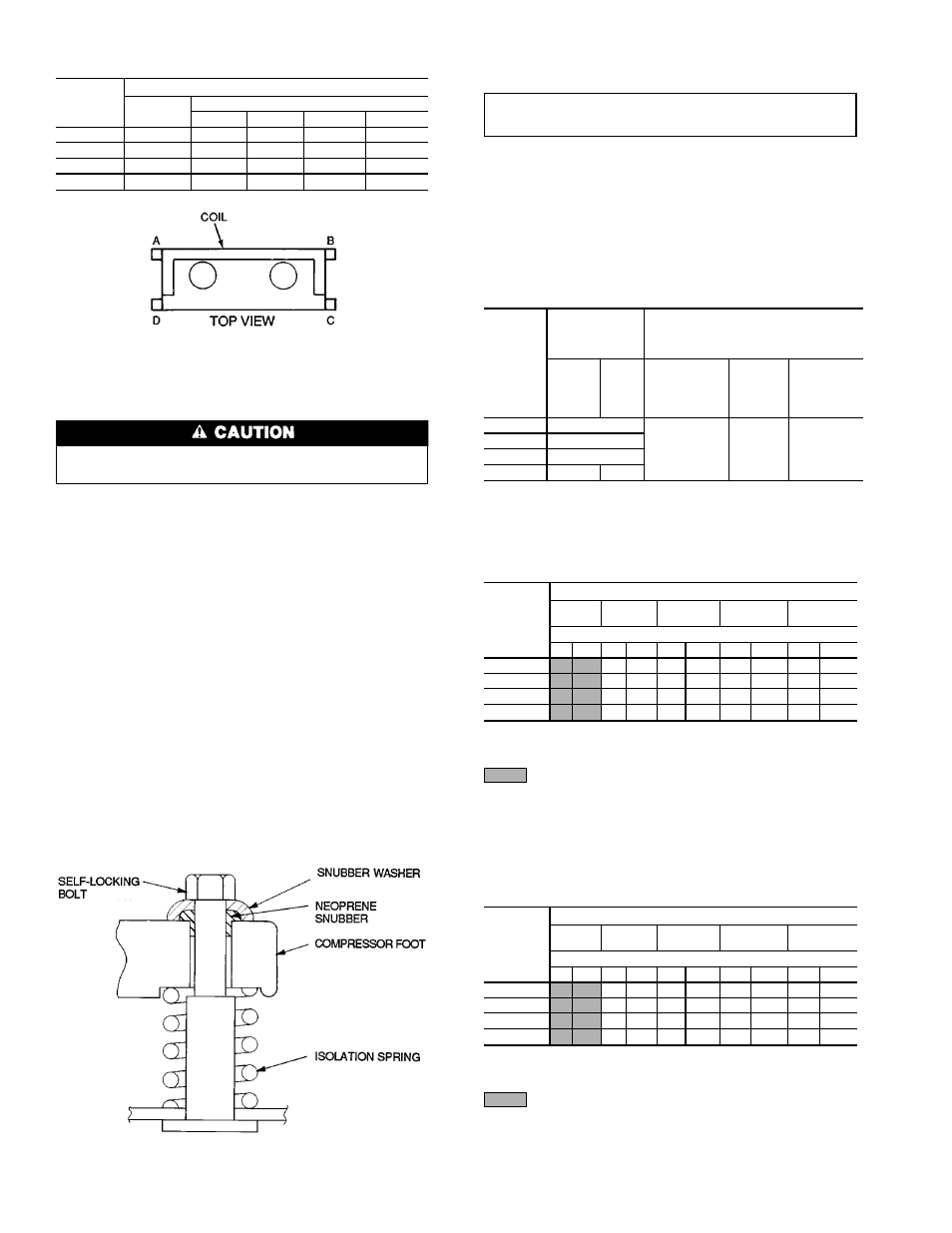

Table 2 — Weight Distribution

UNIT

WEIGHT — lb (kg)

Total

Operating

Support Point

A

B

C

D

38AE012

732 (333)

142 (65)

138 (63)

225 (102)

227(103)

38AE014

779 (354)

143 (65)

140 (64)

247 (112)

249 (113)

38AE016

789 (359)

143 (65)

143 (65)

250 (114)

253 (115)

38AKS024

900 (408)

178 (81)

168 (76)

269 (122)

285 (129)

Step 2 — Rig and Mount the Unit

Be sure unit panels are securely in place prior to

rigging.

RIGGING — These units are designed for overhead rigging

only. For this purpose, the transverse base channels extend

beyond the sides of the unit, with holes provided in the end

plates to attach cables or hooks. Rig with top skid packaging

assembly in place to prevent unit damage by the rigging cable.

As further protection for the coil faces, plywood sheets can

be placed against the sides of the unit, behind the cables.

Run the cables to a central suspension point so that the angle

from the horizontal is not less than 45 degrees. Raise and set

the unit down carefully.

If it is necessary to roll the unit into position, mount the

unit on longitudinal rails, using a minimum of 3 rollers. Ap-

ply force to the rails, not the unit. If the unit is to be skidded

into position, place it on a large pad and drag it by the pad.

Do not apply any force to the unit.

Raise from above to lift unit from the rails or pad when

unit is in final position.

COMPRESSOR MOUNTING — As shipped, the compres-

sor is held tightly in place by self-locking bolts.

Before start-

ing unit, loosen self-locking bolts until the snubber

washer can be moved sideways with finger pres-

sure. Do not remove shipping bolts. See Fig. 3.

Step

3

—

Complete

Refrigerant

Piping

Connections

IMPORTANT: A refrigerant receiver is not provided

with the unit. Do not install a receiver.

SIZE REFRIGERANT LINES — Consider the length of

piping required between outdoor unit and indoor unit

(evaporator), the amount of liquid lift, and compressor oil

return. See Tables 3, 4A, and 4B and also refer to Part 3 of

Carrier System Design Manual for design details and line

sizing. Refer to indoor installation instructions for addi-

tional information.

Table 3 — Liquid Line Data

UNIT

MAXIMUM

ALLOWABLE

LIQUID LIFT

ft (m)

LIQUID LINE

60 Hz

50 Hz

Maximum

Allowable

Pressure Drop

psig (kPa)

Maximum

Allowable

Temp.

Loss

F (C)

Filter Drier

and

Sight Glass

Flare Conn.*

in. (mm)

38AE012

52 (15.8)

7 (48.3)

2 (1.1)

5

⁄

8

38AE014

67 (20.4)

38AE016

82 (25)

38AKS024 87 (26.5) 86 (26)

*Inlet and outlet.

NOTE: Data shown is for units operating at 45 F (7.2 C) saturated suction and

95 F (35 C) entering air.

Table 4A — Refrigerant Piping Sizes — 60 Hz

UNIT

LENGTH OF INTERCONNECTING PIPING — FT (M)

0-15

(0-4.6)

15-25

(4.6-7.6)

25-50

(7.6-15.2)

50-75

(15.2-22.9)

75-100

(22.9-30.5)

Line Size — in. OD

L

S

L

S

L

S

L

S

L

S

38AE012

1

⁄

2

1

1

⁄

8

1

⁄

2

1

1

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

5

⁄

8

38AE014

1

⁄

2

1

1

⁄

8

1

⁄

2

1

3

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

5

⁄

8

7

⁄

8

1

5

⁄

8

38AE016

1

⁄

2

1

3

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

5

⁄

8

7

⁄

8

1

5

⁄

8

7

⁄

8

2

1

⁄

8

38AKS024

5

⁄

8

1

5

⁄

8

5

⁄

8

1

5

⁄

8

7

⁄

8

1

5

⁄

8

7

⁄

8

2

1

⁄

8

7

⁄

8

2

1

⁄

8

LEGEND

L — Liquid

S — Suction

Close coupled.

NOTES:

1. Pipe sizes are based on a 2 F (1.1 C) loss for liquid lines and a 1.5 F

(0.8 C) loss for suction lines.

2. Pipe sizes are based on an equivalent length equal to the maximum length

of interconnecting piping plus 50% for fittings. A more accurate estimate may

result in smaller sizes.

Table 4B — Refrigerant Piping Sizes — 50 Hz

UNIT

LENGTH OF INTERCONNECTING PIPING — FT (M)

0-15

(0-4.6)

15-25

(4.6-7.6)

25-50

(7.6-15.2)

50-75

(15.2-22.9)

75-100

(22.9-30.5)

Line Size — in. OD

L

S

L

S

L

S

L

S

L

S

38AE012

1

⁄

2

1

1

⁄

8

1

⁄

2

1

1

⁄

8

5

⁄

8

1

1

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

3

⁄

8

38AE014

1

⁄

2

1

1

⁄

8

1

⁄

2

1

1

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

3

⁄

8

38AE016

1

⁄

2

1

3

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

5

⁄

8

38AKS024

5

⁄

8

1

5

⁄

8

5

⁄

8

1

5

⁄

8

5

⁄

8

1

5

⁄

8

7

⁄

8

1

5

⁄

8

7

⁄

8

1

5

⁄

8

LEGEND

L — Liquid

S — Suction

Close coupled.

NOTES:

1. Pipe sizes are based on a 2 F (1.1 C) loss for liquid lines and a 1.5 F

(0.8 C) loss for suction lines.

2. Pipe sizes are based on an equivalent length equal to the maximum length

of interconnecting piping plus 50% for fittings. A more accurate estimate may

result in smaller sizes.

Fig. 3 — Compressor Mounting

6