Carrier 58CMA User Manual

Page 10

c. Use of an oversized nozzle input.

d. Pump pressure over values listed in Table 10.

5. The CO

2

and stack temperature instruments enable you to

obtain data required to determine thermal efficiency of fur-

nace.

6. An oil filter should be installed as close to burner as possible

with ALL oil burners and is essential on lower firing rate

burners. We recommend the use of a low pressure drop oil

filter such as the General Filter, Inc. model #1A-25A or

equivalent.

7. The oil pressure regulator is factory set to give oil pressure of

100 psi for the model having 105,000 BTUH input and 100 psi

for the model having 119,000 BTUH input. The firing rate

noted on nameplate may be obtained using the nozzles and

pump pressures indicated in Table 10.

Table 10—Burner Input and Nozzle Size at 100 psi

Pump Pressure

FURNACE

INPUT

(BTUH)

INPUT

USGPH

NOZZLE

REAL PUMP

PRESSURE

SPECIFICATION

PUMP PRESSURE

70,000

0.50

0.50-70W

100

100

91,000

0.65

0.55-70B

140

140

105,000

0.75

0.65-70B

133

130

120,000

0.85

0.75-70B

128

130

140,000

1.00

0.85-70B

138

140

155,000

1.10

0.85-70B

167

170

8. On a new installation, air entrapped in oil line leading from

tank to nozzle must be thoroughly purged in order to prevent

excessive after drip. The oil pump is provided with a special

fitting which allows purging of any air between tank and oil

pump. The proper procedure for performing this operation is

as follows:

a. Place a piece of clear plastic 1/4 in. diameter tubing over

purge fitting on oil pump.

b. Start oil burner, then open purge fitting and allow burner to

run until purge tube is completely free of air bubbles.

c. Tighten purge fitting. Allow oil to run to nozzle and fire

burner.

d. If purging takes longer than 15 sec and no flame has been

established, burner stops. Push reset button on front of

primary control to restart burner.

e. For detailed information on operation of primary control,

refer to instructions included with furnace.

After all the setup procedures mentioned above have been com-

pleted, the burner should be allowed to operate and an inspection

mirror should be used to observe the flame pattern at tip of nozzle.

Any irregularities such as burning to 1 side or pulsating flame

patterns should be corrected by changing nozzle.

Step 3—Fan Adjustment Check

This furnace is equipped with a 4-speed direct-drive motor to

deliver a temperature rise within range specified on rating plate,

between return and supply plenums, at external duct static pressure

noted on rating plate.

When operating furnace in heating mode, static pressure and

temperature rise (supply-air temperature minus return-air

temperature) must be within those limits specified on rating

label. Failure to follow this warning could lead to severe

furnace damage.

Adjust fan speed ACCORDING TO OIL INPUT SELECTED so

that temperature rise is within rise range specified on rating plate.

(See Table 11.) Consult wiring diagram for speed changes on

direct-drive motor.

Table 11—Speed Selection

UNIT

SIZE

FURNACE

INPUT

(BTUH)

RECOMMENDED

BLOWER

SPEED

105-12/

120-20

70,000/119,000

Med-Low

91,000/140,000

Med-High

105,000/154,000

High

.

To adjust fan off time, set DIP switches on control board to obtain

desired timing. (See Fig. 5.)

Step 4—Limit Control Check

After furnace has been in operation for at least 15 minutes, restrict

return-air supply by blocking filters or closing return registers and

allow furnace to shut down on high limit. The burner should shut

off, and main blower should continue to run.

Remove restriction, and burner should come back on in a few

minutes.

Step 5—For Year-Round Air Conditioning

This furnace is designed for use in conjunction with cooling

equipment to provide year-round air conditioning. The blower has

been sized for both heating and cooling, however, fan motor speed

may need to be changed to obtain necessary cooling airflow.

Step 6—Heating

The blower speed is factory set to deliver required airflow at

normal duct static pressure.

Step 7—Cooling

The blower speed may be field adjusted to deliver required airflow

for cooling application. (See Table 12.)

Step 8—Constant Blower Switch

This furnace is equipped with a constant low-speed blower option.

Whenever room thermostat is not calling for heating or cooling,

blower runs on low speed in order to provide air circulation. If

constant blower option is not desired, the rocker switch on top of

cabinet may be used to turn off constant speed.

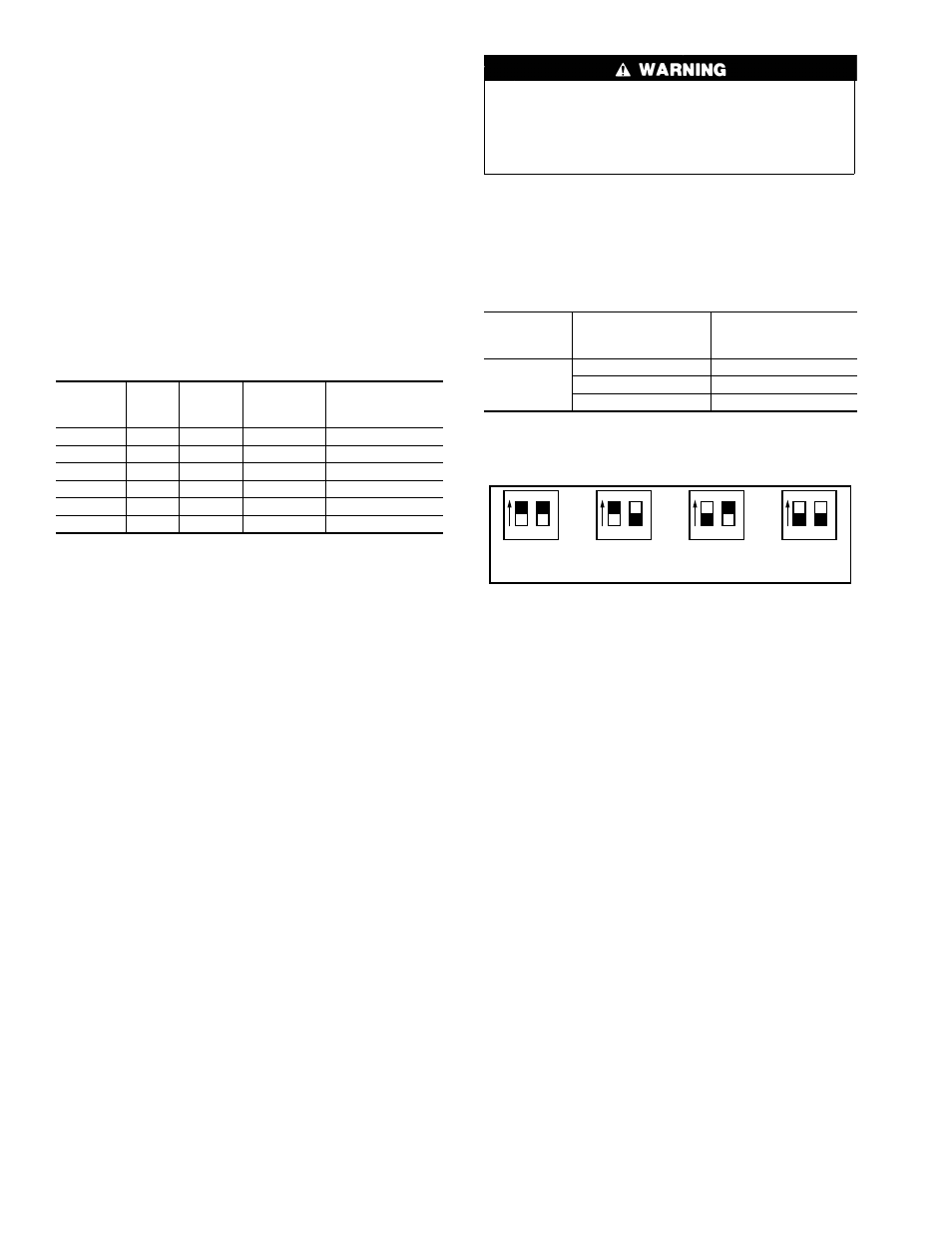

Fig. 5—Fan Off Time DIP Switch Settings

(Black Box Represents Switch Position)

A95115

1

2

60 Sec

1

2

90 Sec

DELAY OFF DIP SWITCH SETTINGS

1

2

1

2

1

2

120 Sec

1

2

150 Sec

10

→

→