Care of your reverse osmosis system – Kenmore ULTRAFILTER 300 625.384720 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CARE OF YOUR REVERSE OSMOSIS SYSTEM

TUBING CONNECTION (continued)

To Disconnect Tubing: Push the collet inward and

hold with a finger while pulling the tubing out.

FiG. 11 -A

Tubing correctly cut and connected

auttub.ngs^quar.

collet

I

end of tubing round and

smooth, with no cuts,

nicks or flat spots

11/16?' Í1»” tubing

r

engagsnwit

9/4" tjjbing)

FiG. 11-B

collet (depress to

remove tubing)

\

'

tubing

Replacing collet and

cxing seal

Push o-ringsealinto

bottom of port, then

follow with collet.

o-ring seal

collet

Changing Collet and O-ring (FIG. 11):

1. With a small screwdriver remove the collet and o-

rmg from the fitting. Be careful not to scratch the in

ternal walls of the collet port

2. Be sure the port is clean, then lubricate and insert

the o-ring seal to the bottom of the port.

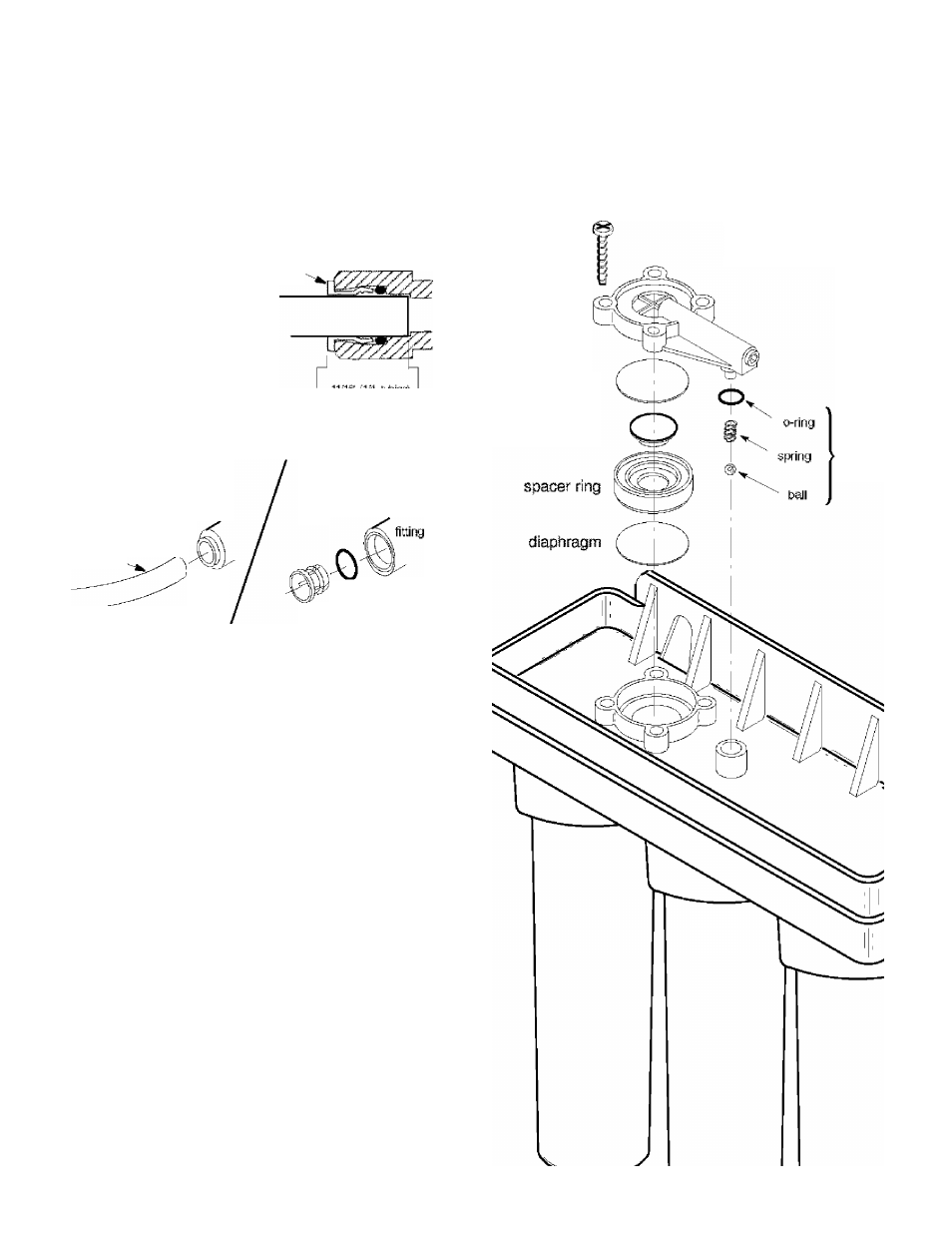

AUTOMATIC SHUTOFF SERVICE

If the shutoff assembly requires service, be sure to

reassemble parts exactly as shown in FIG. 12.

FIG. 12

3. Push the collet inward until it locks in place.

I- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

I

CAUTION

I

I

DO NOTUSE VINEGAR OR OTHER ACIDBASED

I

I

CLEANERS ON THIS RO SYSTEM. THEY WILL

j

I DEGRADE SOME RO SYSTEM PARTS. ALWAYS |

I USE SOAP AND WATER.

I_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ I

I- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

j

THs reverse osmosis system contains a replaceable

j

I

treatment component critical for effective removal

I

I

of totaidissolvedsolids. The water should be tested

I

I periodically to verify the system is per fornnng sa tis- |

I factoriiy.

I

I_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ I

14

Problems, Questions? Call 1 -800-

screw (4)

diaphragm

plunger

SHUTOFF

ASSEMBLY

check

valve

426-9345 Kenmore Water Line