Use & care information, Water requirements, Warning – Whirlpool System I User Manual

Page 10: Tgeneral tips, Maintaining your water fiitration system, Replacing filter cartridges, Preparation for long periods of non-use

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Use & Care Information

Water Requirements

The filtration system must be connected to a cold

water supply line providing 30-100 psi water pressure.

The water temperature must be between 40°-100°F.

Community or private well water must be potable

(suitable for drinking).

! WARNING

Personal Injury Hazard

DO NOT use water filtration system if water is

microbioiogicaiiy unsafe or water quaiity is

unknown. Faiiure to follow these instructions

could result in personal injury.

30

I

nut

t

General tips

• To correct a leaky saddle

valve, turn off cold water

supply and make sure bot

tom screw Is tightened evenly

and firmly. DO NOT overtighten, you could crush

the pipe. Then make sure the nut below the

saddle valve's handle is tight. If not, tighten it

with a %" wrench.

• If the threaded portion of the brass compression nut

that is attached to the saddle valve leaks, turn off

saddle valve and remove the nut, wrap Teflon tape

around the threaded portion 2-4 times. Reconnect

the nut.

• If a leak should occur at a push-in connector, the

cause is usually defective tubing. To correct the

problem, turn off water supply to the

system either at the saddle valve or

other existing water valve. Push in the

grey push-in connector and hold; then

.

pull the tubing out of the connector. Cut

“

\

at least V4" from the end of the tubing

clean, square cut

using a plastic tubing Cutter or a sharp

razor knife. Make sure the cut end is clean and blunt

and that tubing is round. Reinsert tubing as far as it

will go. Turn on water supply at valve.

• If the refrigerator tubing leaks at the push-in connec

tor, the refrigerator's water line metal tubing may be

grooved or deformed. To correct the problem, turn

off water supply to the system either at the saddle

valve or other existing water valve. Press refrigerator

water supply or optional sink faucet to drain water

from system. Wait five minutes for filtration assembly

to depressurize. Push in the grey push-in connector

and hold; then pull the tubing out of the connector.

Cut at least 'A" from the end of the tubing to create a

new smooth end or replace if necessary.

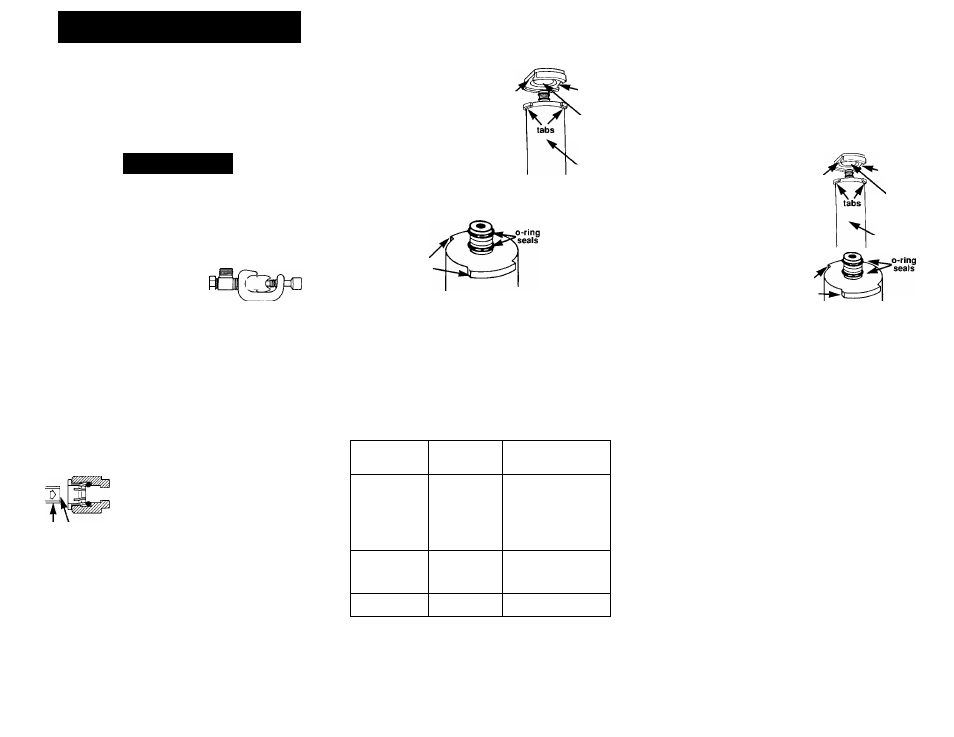

' If a cartridge head leaks, it may

have a misaligned, pinched or

damaged 0-ring. Shut off the slot

saddle valve or other existing

water valve. Press refrigerator

water supply or optional sink

faucet to drain water from system

Wait five minutes for filtration

assembly to depressurize. Turn

filter cartridge V4 turn to the left

and remove. Replace the 0-ring if

it is misaligned, pinched or damaged.

slot

receptacle

cartridge

tabs

Maintaining your water

fiitration system

The maximum length of time a filter cartridge should

be used is one year. Cartridges should be replaced

every 500 gallons, but exactly how often cartridges

are replaced will depend on local water conditions.

Private wells may require more frequent cartridge

replacement while softened water systems may

require cartridge replacement only once a year.

Cartridge

Replace at least

Or replace if or when...

Sediment (SC)

Once/year or

every 1,000 gals.

•Water supply is cloudy,

has high dirt and rust

content (change every

six months)

• Water amount or flow

from faucef is noticeably

reduced

•Water supply smells

of chlorine

Lead Reductien (L)

Once/year or

every 500 gals.

•Wafer supply smells

of chlorine or water

has high dirt and rust

content (change every

six months)

Carbon (CF)

Once/year or

every 500 gals.

•Water has “off" fasfe

or odor

Maintenance of this water filtration system is very important.

Replace the Sediment (S), Lead Reduction (L), and Carbon Filter

(CF) cartridges annuaiiy. Faiiure to maintain this water filtration

system over an extended period of fime could present health

risks.

10

slot

receptacle

cartridge

Replacing filter cartridges

1. Turn off water supply at either saddle valve or

main shut-off. Press refrigerator water dispenser to

empty water into a container. If using the optional sink

faucet, turn on faucet to drain any water in system.

Discard this water. Wait five minutes for filtration

assembly to depressurize.

2

.

Lift cover off filtration assem

bly. Rotate cartridge one-quarter

turn to the left to remove connector

tabs from receptacle. Gently pull

down to remove cartridge.

3

.

Check that label on new cartridge

matches label above cartridge recep

tacle. Remove red cap from

cartridge. Wet 0-ring seals

of new cartridge with a little

water. Line up the tabs at the ^

top of the new cartridge with the slots in the filtration

assembly's receptacle. Push cartridge up and turn it 'A

turn to the right to lock it into place. Cartridge label

must face front. Pull down on cartridge to make sure it's

firmly in place. Repeat step if cartridge disconnects.

4

.

Turn water supply back on and check for leaks.

Open faucet and allow water to run for 5 minutes to

check system for leaks. If water is leaking, shut off

water and recheck connections. Replace cover.

Preparation for long periods of non-use

Follow these instructions if system will not be used for

more than 30 days.

1. Turn off water supply at either saddle valve or

main shut-off. Press refrigerator water dispenser to

empty water into a container. If using the optional sink

faucet, turn on faucet to drain any water in system.

Discard this water. Wait five minutes for filtration

assembly to depressurize.

2

.

Remove all cartridges and place upside down in

sink or bucket to drain water from cartridges. Place

cartridges in plastic bag and seal tightly. Place bag

with cartridges in refrigerator. Do Not allow cartridges

to freeze.

Using water filtration system after long

periods of non-use

1. Follow instructions for replacing cartridges.

2

.

Follow "Start Up” instructions (3e and 3f).