Cowl installation – Carl Goldberg GBGA1075 User Manual

Page 15

15

3. Install the tank in the fuselage in the notches

provided in the bulkhead, and hold in place with

foam(not provided). Attach the fuel lines(not

provided) to the three metal lines and route

through the hole in the firewall and to your

engine. If you are using an engine without a

pump or pressure system you will probably

have to mount the tank in the nose of the plane.

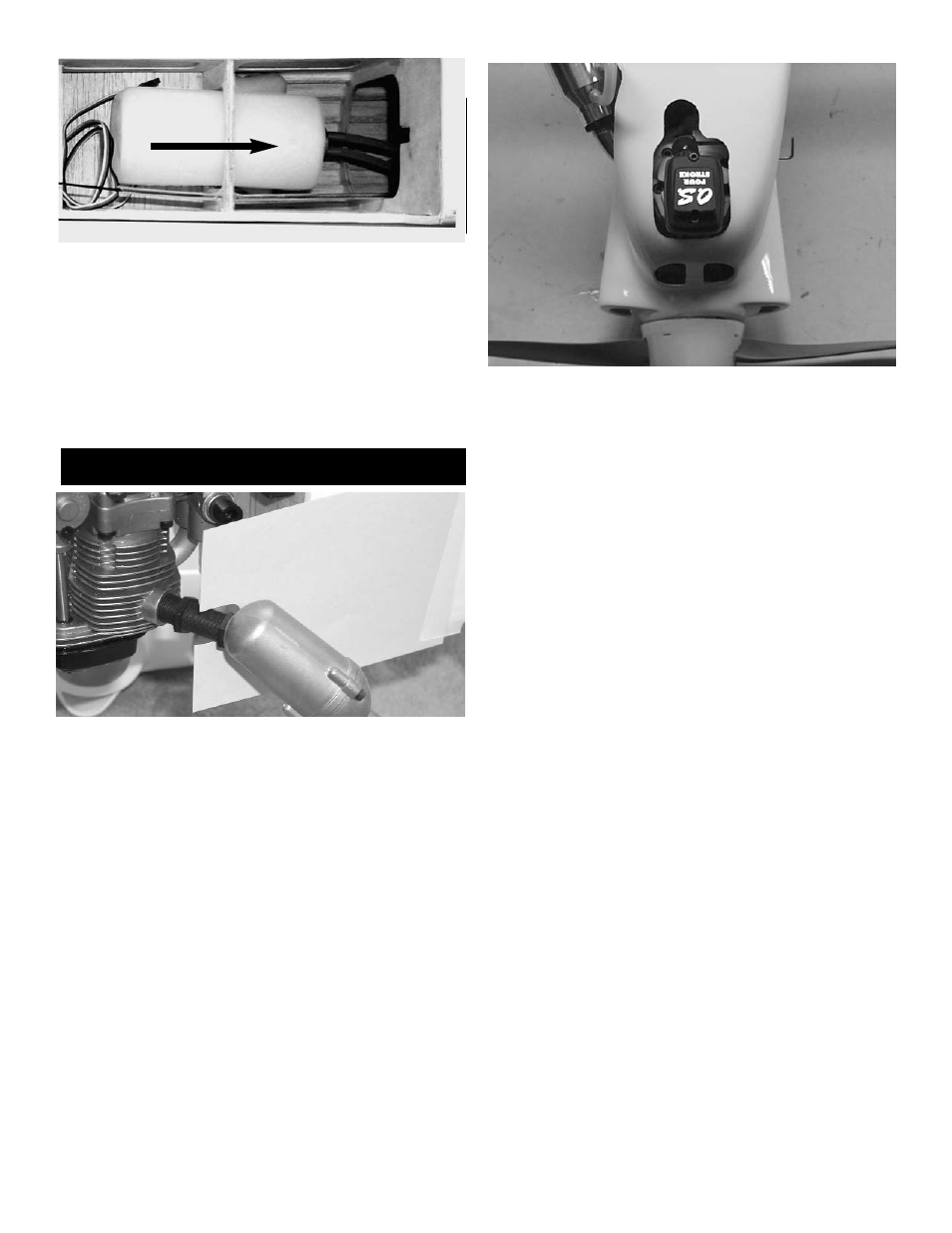

Cowl installation

1. The easiest way to cut the opening for the

muffler, needle valve, and head is to use a

piece of cardboard and cut it to fit around the

part you are fitting. Tape the cardboard to the

fuselage about 1” behind where the cowl will

end. You can now remove the muffler, slide the

cowl in place and transfer the hole to the cowl

from the paper template. You will need to start

with the head because the cowl will not go on

until the head clearance is cut. A Dremel tool

with a cutter and a sanding drum does the best

job.

2. After all the cutouts are made in the cowl, you

can use the same method to mount the cowl.

Tape the paper templates to the fuse side and

make a hole that will be in line with the firewall.

This needs to be about 1/8” back from the front

edge of the firewall so the screws will hit the

solid wood of the firewall and not just the soft

balsa of the sides. With the templates in place,

install the cowl and put your spinner back plate

in place. Place a 1/8” shim between the cowl

and spinner backplate and tape in place. When

satisfied with the alignment of the cowl, transfer

the holes from the paper templates to the cowl.

Remove the cowl and drill 5/64” holes at this

location. Reinstall the cowl and tape back into

position. Use a 1/16” drill to drill pilot holes for

the screws through the holes in the cowl. Install

with the 2mm screws provided. It is a good idea

to remove the cowl and harden the mounting

holes by dropping a couple of drops of thin CA

into each hole. Let cure before reinstalling.