CAMCORP HVP with Roots Blower User Manual

Page 63

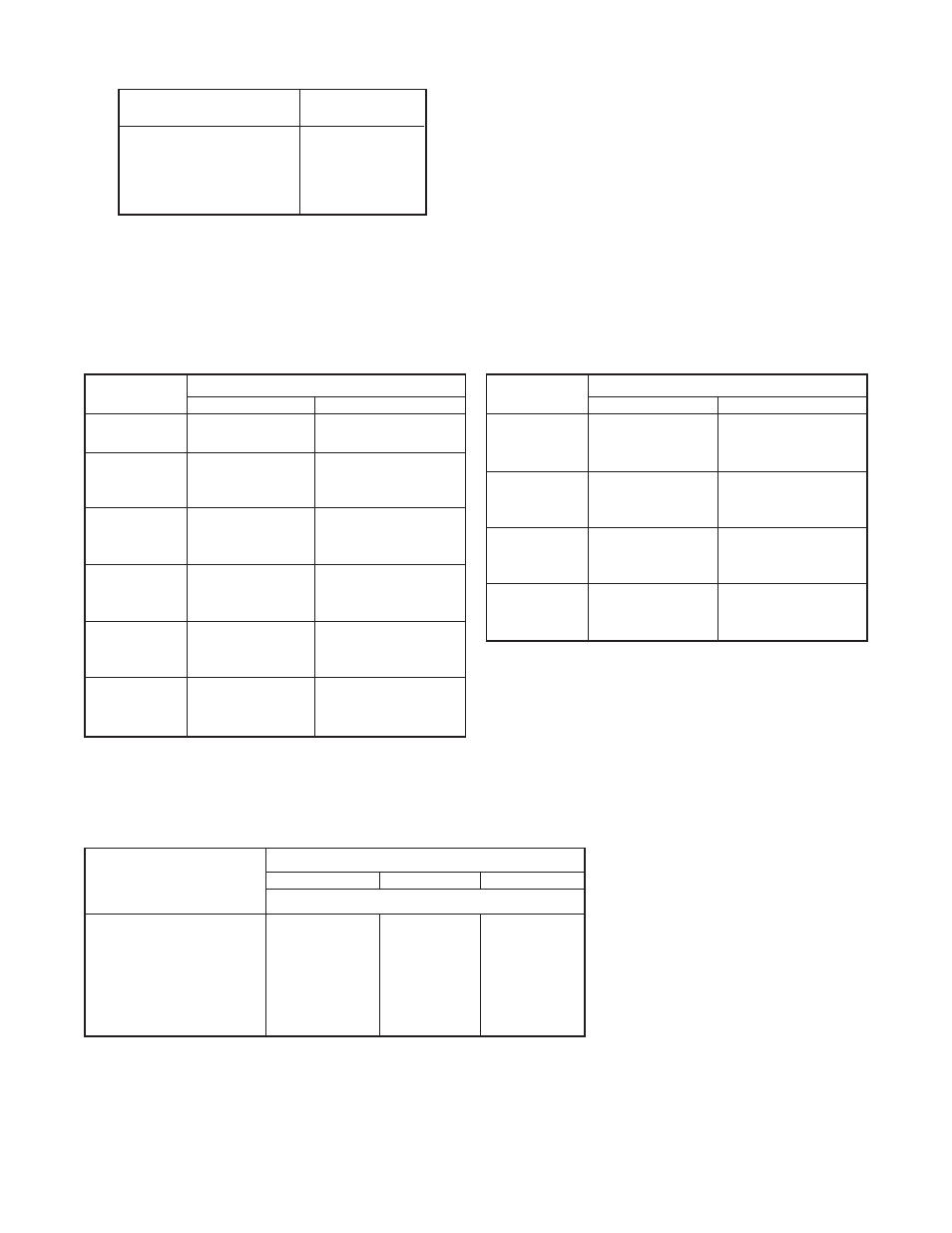

Frame Size

Drive End Capacity Fl. Oz. (Liters)

Vertical

Horizontal

32

4.0 (.12)

6.5 (.19)

33

4.0 (.12)

6.5 (.19)

36

4.0 (.12)

6.5 (.19)

42

5.5 (.16)

10.8 (.32)

45

5.5 (.16)

10.8 (.32)

47

5.5 (.16)

10.8 (.32)

53

7.5 (.22)

14.8 (.44)

56

7.5 (.22)

14.8 (.44))

59

7.5 (.22)

14.8 (.44)

65

16 (0.47)

31 (0.91)

68

16 (0.47)

31 (0.91)

615

16 (0.47)

31 (0.91)

16

Ambient

ISO

Temperature °F (°C)

Viscosity No.

Above 90° (32°)

320

32° to 90° (0° to 32°)

220

0° to 32° (-18° to 0°)

150

Below 0° (-18°)

100

UNIVERSAL RAI, URAI-J, URAI-G

Frame Size

Gear End Capacity Fl. Oz. (Liters)

Vertical

Horizontal

22

3.4 (.1)

6.1 (.18)

24

3.4 (.1)

6.1 (.18)

32

8.5 (.25)

16.0 (.47)

33

8.5 (.25)

16.0 (.47)

36

8.5 (.25)

16.0 (.47)

42

12.7 (.37)

22.8 (.67)

45

12.7 (.37)

22.8 (.67)

47

12.7 (.37)

22.8 (.67)

53

16.0 (.47)

27.6 (.82)

56

16.0 (.47)

27.6 (.82)

59

16.0 (.47)

27.6 (.82)

65

28.3 (.84)

52.1 (1.54)

68

28.3 (.84)

52.1 (1.54)

615

28.3 (.84)

52.1 (1.54)

76

32.3 (.96)

59.5 (1.76)

711

32.3 (.96)

59.5 (1.76)

718

32.3 (.96)

59.5 (1.76)

Table 4 - Universal URAI series with Grease Lubricated Drive End: Specified Bearing

Greasing Intervals

Speed In RPM

Operating Hours Per Day

8

16

24

Greasing Intervals in Weeks

750-1000

7

4

2

1000-1500

5

2

1

1500-2000

4

2

1

2000-2500

3

1

1

2500-3000

2

1

1

3000 and up

1

1

1

Table 2 - Recommended Oil Grades

UNIVERSAL URAI series-DSL Splash Lubricated Drive End

URAI GAS Blower Oil and Grease Specifications

The specified oil should be ROOTS synthetic P/N 813-106- of

the proper viscosity.

Table 3 - Approximate Oil Sump Capacities

The specified grease for servicing drive

end bearings of a Gas blower, use a NLGI

#2 premium grade aluminum complex*

grease, ROOTS P/N T20019001 with

300°F (149°C) service temperature and

moisture resistance and good mechanical

stability.

When servicing drive end bearings of Non

Gas blower, use a NLGI #2 premium

grade microgel grease with 250°F (121°C)

service temperature and moisture resist-

ance and good mechanical stability.

ROOTS specifies Shell Darina EP NLGI

Grade 2. Product Code 71522.

NOTE: Lithium based greases are not

compatible with the ROOTS Synthetic

grease used when assembling a Gas

blower or the non-soap base grease used

when assembling a standard URAI blower.

Lithium based grease is not approved for

any ROOTS blowers.

See page 14 and 15 for illustration of vertical and horizontal configurations.

These capacities are provided to assist in stocking the correct amount of oil. Exact sump capacities may differ slightly. See

“Lubrication” section for proper filling instructions.

Note that the gear end sump capacity is provided on the adjacent table.