En english – Clarke Propane Floor Burnisher User Manual

Page 10

EN

ENGLISH

Page -10-

Clarke

®

Operator's Manual (EN) - DC Propane Burnisher

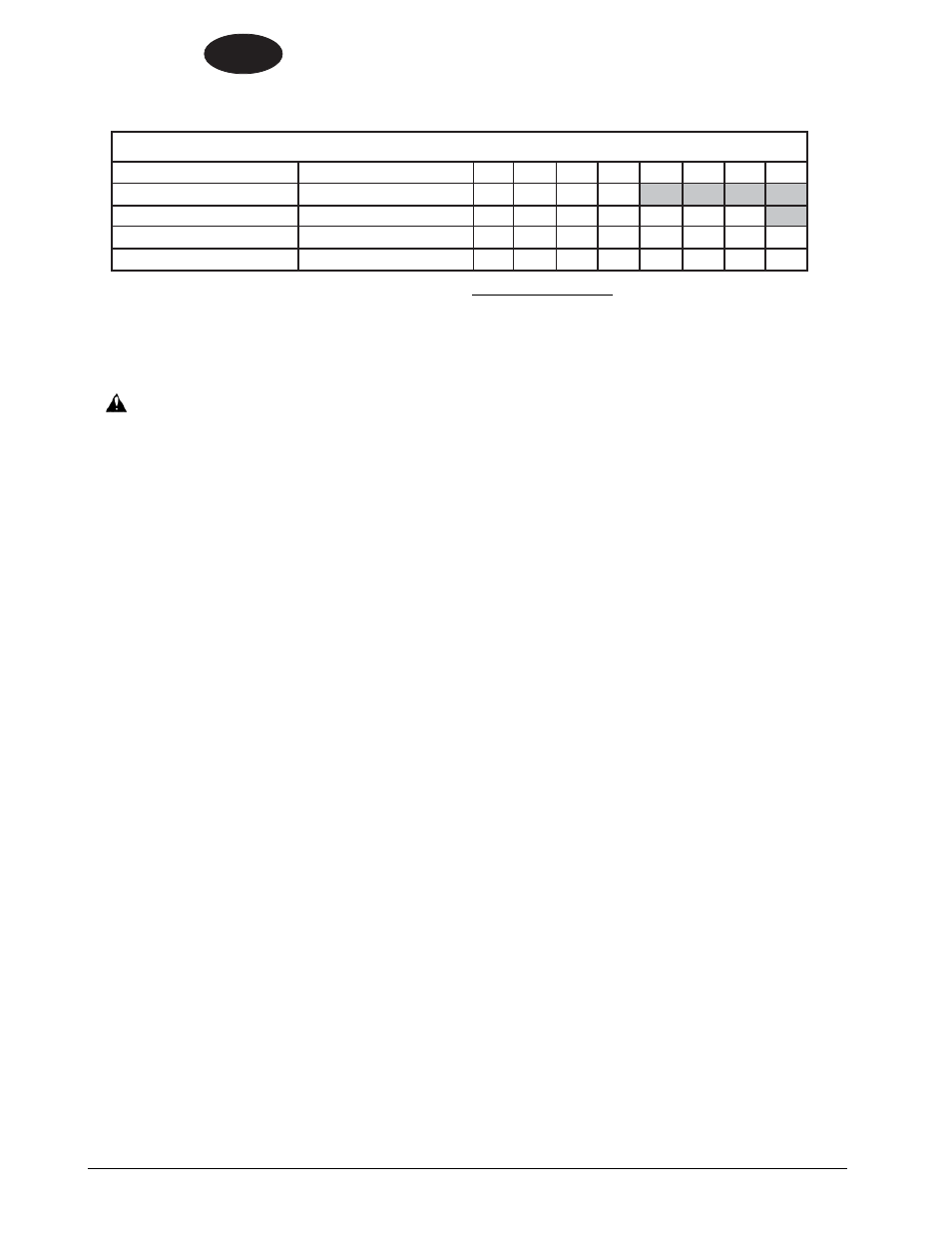

8 Hour Time Weighted Average (OSHA Method)

1.5 % 750,000cf

Hours Operation

1

2

3

4

5

6

7

8

TWA (OSHA Method)

0 change/hr

5

14

27

46

69

96

128 164

1/2 change/hr

4

9

16

24

33

42

50

59

1 change/hr

3

7

11

16

20

25

29

34

2 change/hr

2

4

7

9

11

13

16

18

Based on the CO production rates shown above the TWA would not be exceeded in a

100 x 750 x 10 foot (empty) space after 8 hours with 2 air changes per hour.

(Assumes no additional CO

exposure during 8 hour time period)

Maintenance of Equipment

Warning: The proper maintenance of equipment is vital to safe operation. LPG engines are dependent on

engine tune up, and air filter replacement. CO concentration (production) skyrockets when the air to fuel ratio becomes

fuel rich. Follow the recommended Maintenance Schedule for the engine found in the Engine Operator/Owner Manual as

well as the Maintenance And Adjustments schedule found in the Propane Floor Equipment Operator’s Manual that were

supplied with the equipment. Additional manuals may be obtained by contacting Clarke at 1-800-545-3454 or write to

Clarke Customer Service, 2100 Hwy. 265, Springdale AR 72764.

CO Safety Equipment Available

•

Envirogard automated fuel to air ratio monitoring and regulation providing an optimum combustion

•

Three-way type catalytic converter to scrub CO, Hydro Carbons (HC), and Nitrous Oxide (NOx) from the engine

exhaust providing the lowest possible emissions

•

High cubic feet per minute (CFM) fans (forced air mixing)

•

Digital combustion analyzers for tail pipe emissions monitoring