Problem problem details solution – Kistler-Morse KM LD360s User Manual

Page 28

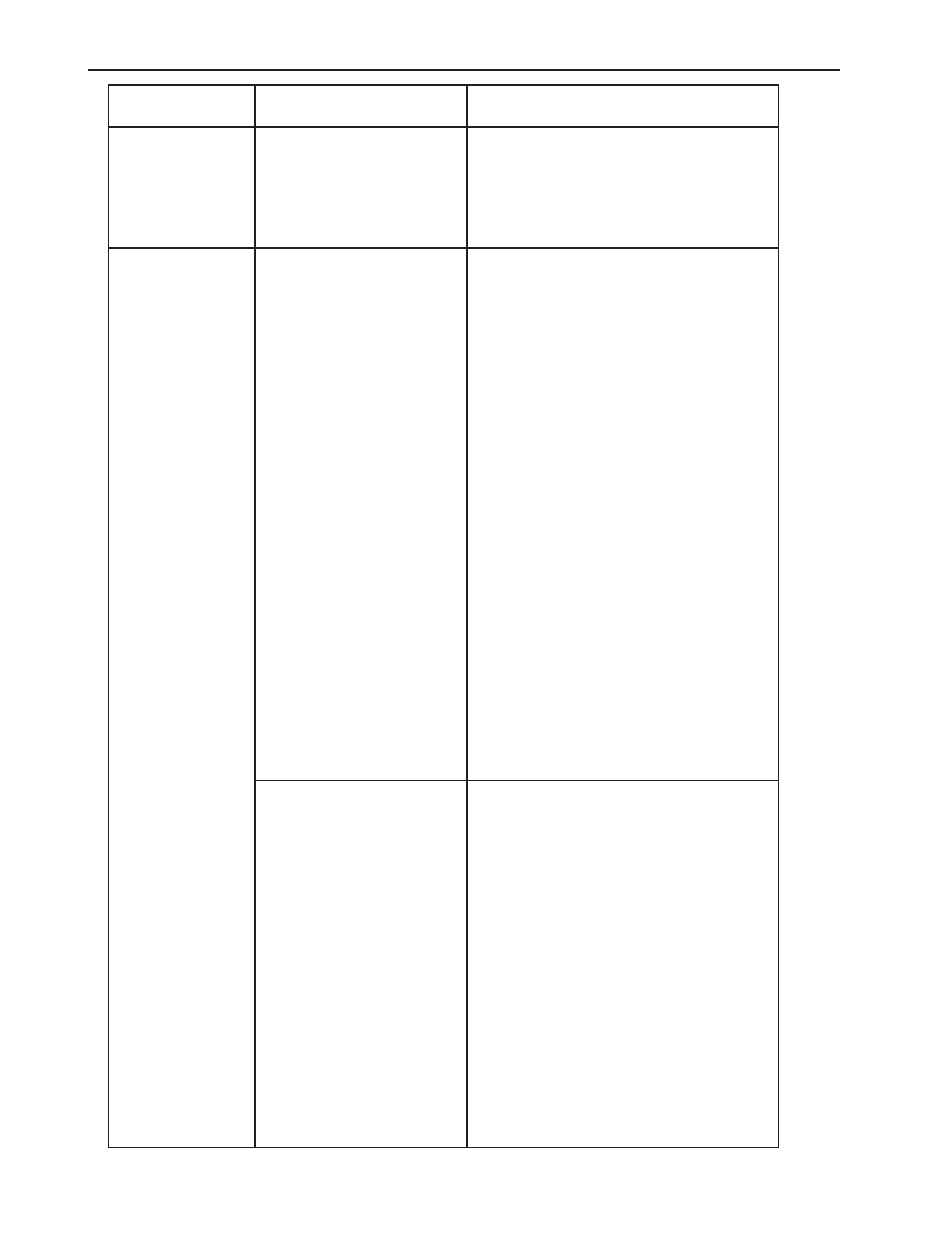

Problem

Problem Details

Solution

Small Amplitude

Changes or Erratic

Fluctuations in

display readings

Fluctuations can be caused

by problems with signal

processor.

Check signal processor excitation voltage

and incoming AC voltage for accuracy and

stability (refer to signal processor manual).

Sudden Change in

Weight Reading or

System Requires

Frequent

Recalibration

One broken Load Disc can

cause indicated weight to

shift up or down by large

amount, up to 100% of full-

scale live load.

Sudden change in weight

reading can be caused by

problems with signal processor.

Check signal processor excitation voltage

and incoming AC voltage for accuracy and

stability (refer to signal processor manual).

Using Digital Multimeter (DMM), check

resistance for individual Load Discs:

1. Set meter resistance scale to accommodate

measured range up to 20,000 ohms.

2. Remove one Load Disc’s wires from

junction box terminal.

3. Put one DMM lead on Load Disc’s white

wire and other lead on brown wire. Record

resistance reading, and verify it is 8,750

± 250 ohms and stable. If reading is outside

this range, Load Disc is damaged and must

be replaced.

4. Put one DMM lead on Load Disc’s white

wire and other lead on black wire. Record

resistance reading, and verify it is 8,750

± 250 ohms and stable. If reading is outside

this range, Load Disc is damaged and must

be replaced.

5. Verify readings from Steps 3 and 4 are

within 400 ohms of each other. If not, Load

Disc is damaged and must be replaced.

6. Repeat Steps 2 through 5 for each suspect

Load Disc, until damaged Load Disc is

located.

Appendix C: Troubleshooting the Load Disc System

C-3