Stainless steel junction box mounting and wiring – Kistler-Morse KM LD360s User Manual

Page 20

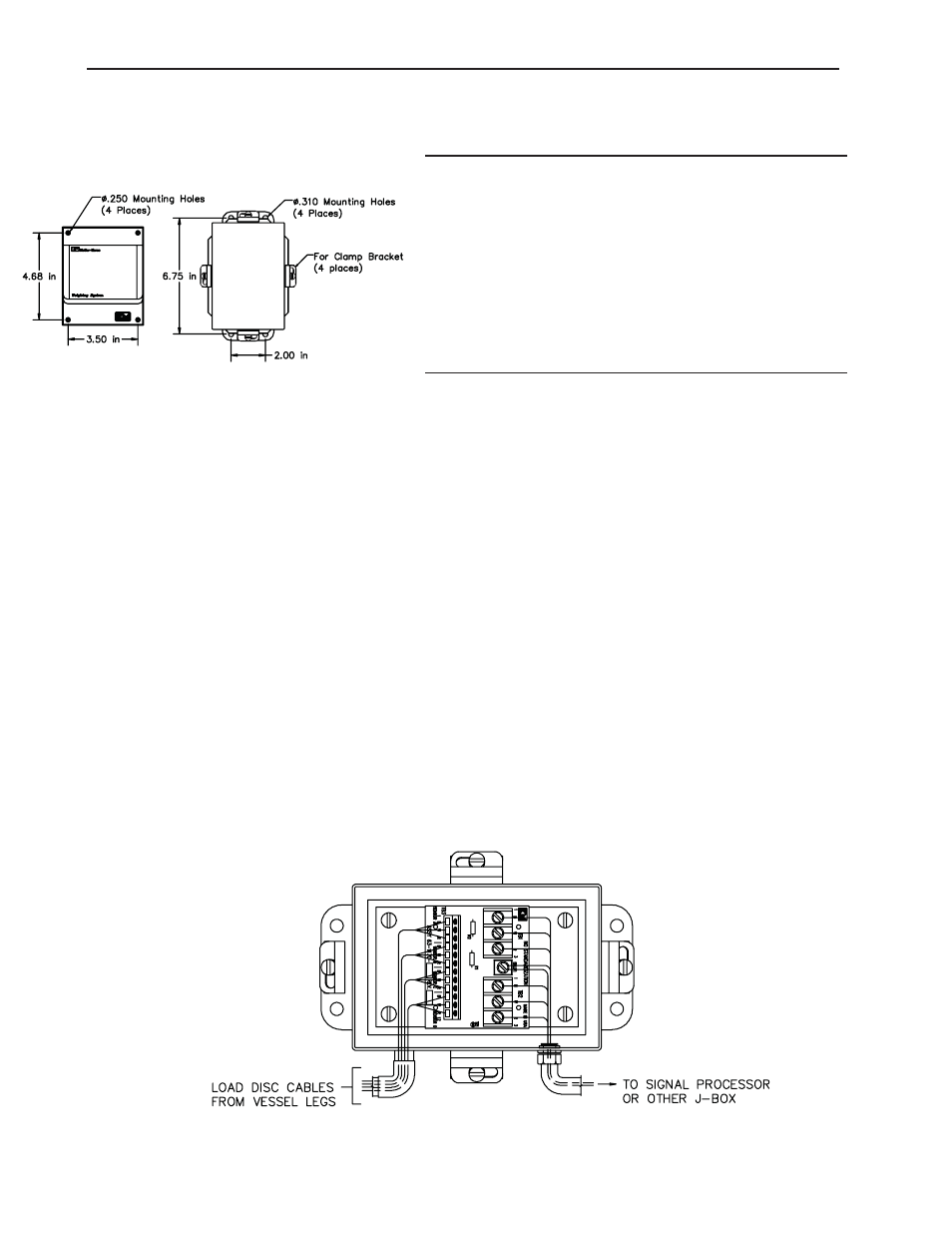

Mounting Junction Box

1.

See Figure 3-7. Hold the junction box at the desired

mounting location. Mark the four mounting holes.

2.

Mount the junction box with #8-32 socket head cap

screws and flat washers per your application. Tighten the

screws until snug.

Wiring Load Discs to Junction Box

See Figure 3-8. The stainless steel junction box accommodates up to

eight Load Discs, with up to two Load Disc wires at each terminal.

Note that the junction box has no pre-cut holes for conduit or fittings.

Follow this procedure:

1.

Prepare junction box —

a.

Remove the junction box cover.

b.

Remove the terminal board from the junction box.

c.

Carefully lay out the conduiting configuration —

the Load Disc cables connect to the terminals on

the left and the signal processor cable connects

on the right. Several Load Disc cables may enter

the box through the same conduit.

d.

Cut the required fitting holes in the bottom and/or

sides of the junction box.

e.

Install liquid tight fittings.

f.

Seal fittings with Sikaflex™ or electrical grade

sealant.

Stainless Steel Junction Box Mounting and Wiring

Figure 3-7: Plastic and

Stainless Steel Junction Box

Mounting

Figure 3-8: Wiring Load Discs to Stainless

Steel Junction Box

Chapter 3: Mounting the Load Disc

3-7