4 | compressor assembly – GEA Bock HGX46 CO2 T User Manual

Page 16

16

D

GB

F

E

96259-12.2014-DGb

Fig. 23

Rigid

fixed point

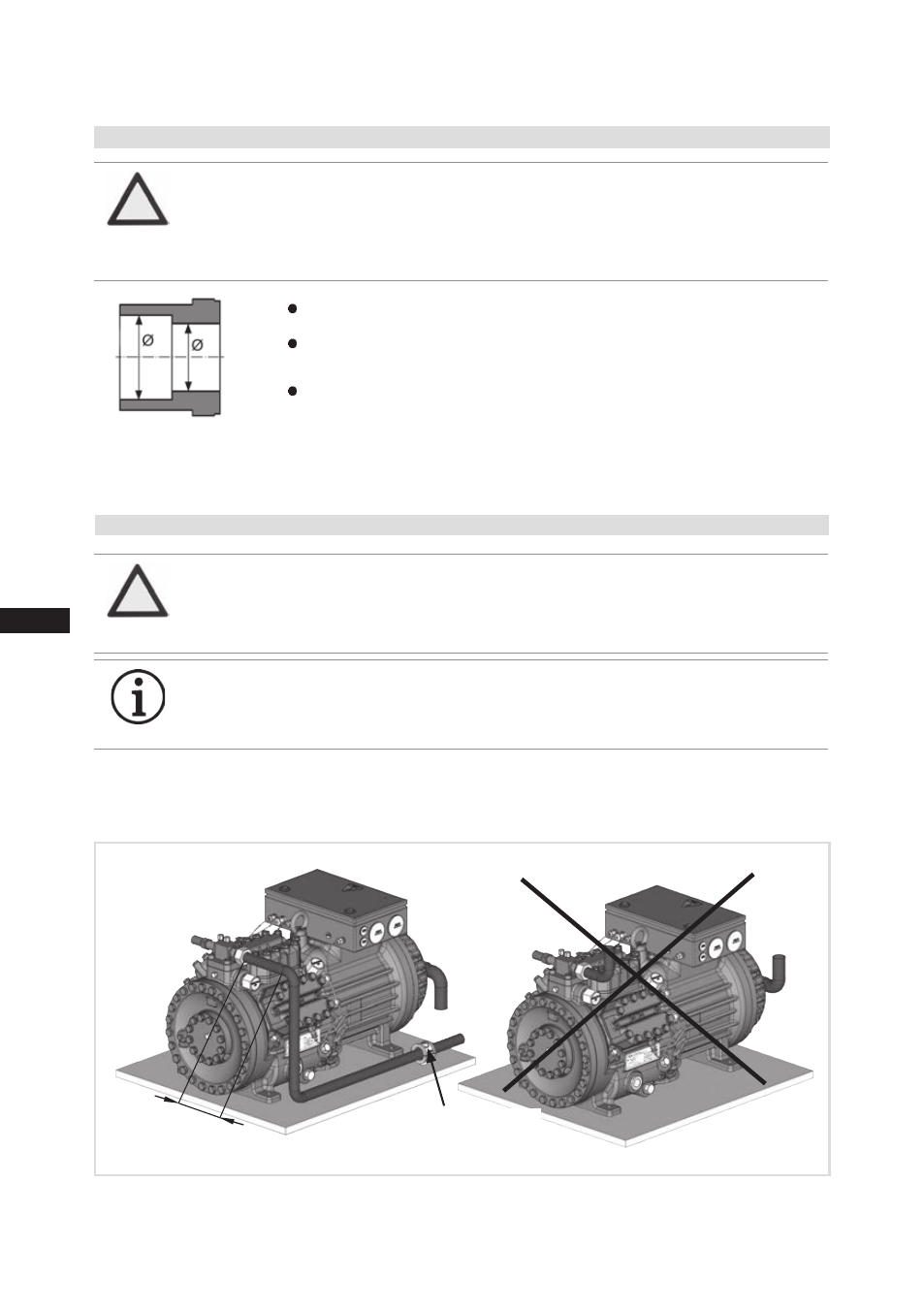

4.10 Laying suction and pressure lines

A rule of thumb:

Always lay the first pipe section starting from the shut-off valve

downwards and

parallel to the drive shaft.

As short as

possible

4| Compressor assembly

ATTENTION Property damage possible.

Improperly installed pipes can cause cracks and tears which can

result in a loss of refrigerant.

INFO

Proper layout of the suction and pressure lines directly after

the compressor is integral to the smooth running and vibration

behaviour of the system.

Material soldering / welding connection: S235 (JRG2C)

The

pipe connections have graduated inside diameters so that pipes with

standart millimetre and inch dimensions can be used.

The connection diameters of the shut-off valves are rated for maximum

compressor output.

The actual required pipe cross section must be

matched to the output. The same applies for non-return valves.

Fig. 22: graduated

internal diameter

4.9 Connecting the pipelines - solder system

ATTENTION Property damage possible.

Remove the valve from the compressor for soldering. Superhea-

ting can damage the valve. Cool the valve body during soldering.

Only solder using inert gas to inhibit oxidation products (scale).