6 | commissioning – GEA Bock HGX2 CO2 T User Manual

Page 20

20

D

GB

F

E

96032-02.2015-DGbF

6 | Commissioning

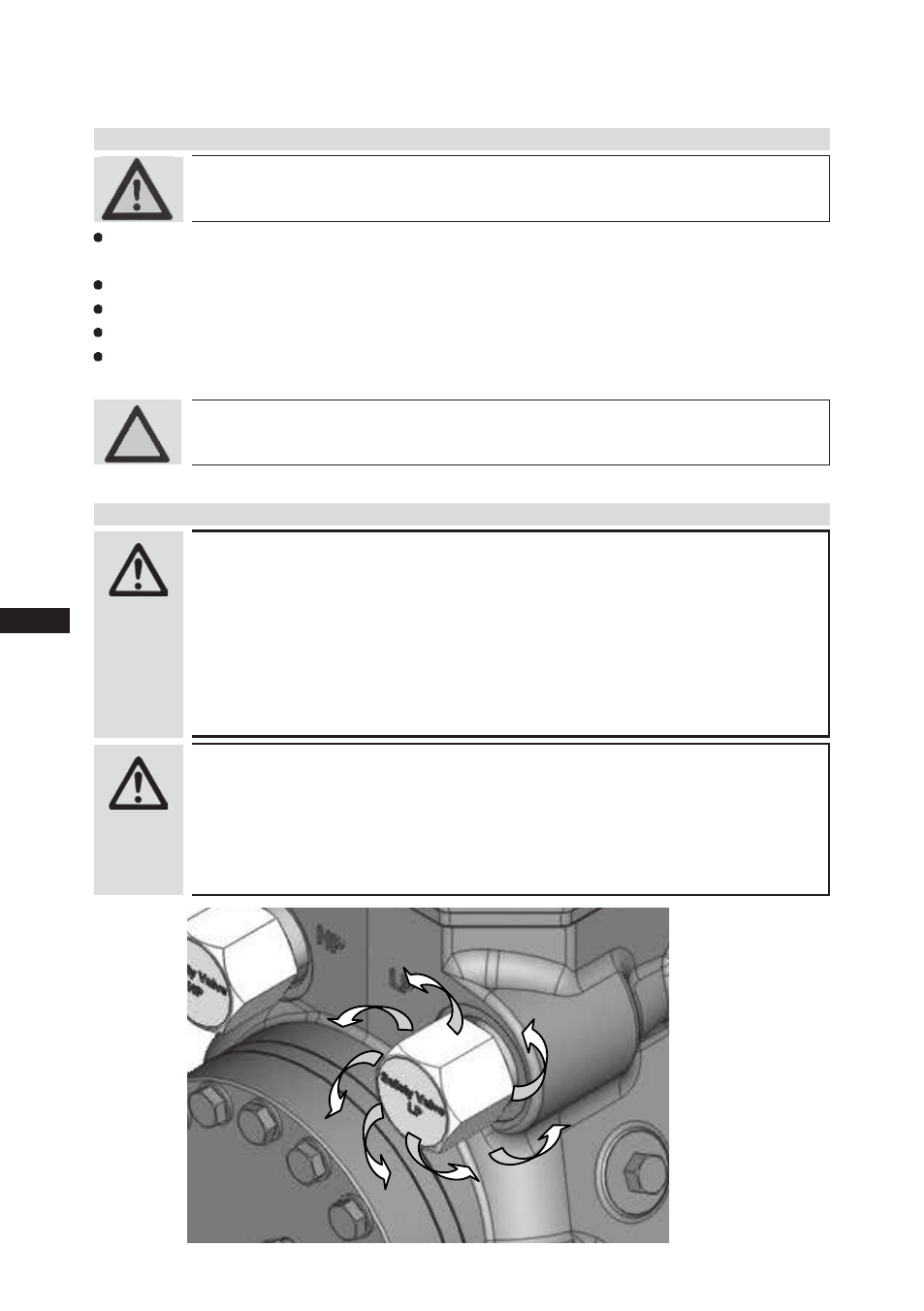

The compressor is fitted with two decompression valves. One valve each on the

suction and discharge side. If excessive pressures are reached, the valves open

and prevent further pressure increase.

Thereby CO

2

is blown off to the ambient (see also Chapter 7.6)!

In the event that a pressure relief valve activates repeatedly, check valve and

replace if necessary as during blow-off extreme conditions can occure, which

may result in a permanent leak. Always check system for refrigerant loss after

activation of pressure relief valve!

6.7 Decompression valve

CO

2

streaming

out

Fig. 21

6.6 Start-up

WARNING! Ensure that both shut-off valves are open before starting the

compressor!

Check that the safety and protection devices (pressure switch, motor protection, electrical contact

protection measures, etc.) are functioning properly.

Switch on the compressor and let it run for at least 10 minutes.

The machine should reach a state of equilibrium.

Check the

oil level: The oil level must be visible in the sight glass.

After a compressor is replaced, the oil level must be checked again. If the level is too high, oil

must be drained off (danger of oil liquid shocks; reduced capacity of the refrigerating system).

ATTENTION! If larger quantities of oil have to be topped up, there is a risk of oil

impact effects. If this is the case, check the oil return!

The decompression valves do not replace any pressure switches and the

additional safety valves in the system. Pressure switches must always be installed

in the system and designed or adjusted in accordance with EN 378-2 or appro-

priate safety standards.

Failure to observe can result in risk of injury from CO

2

streaming out of the two

decompression valves!