3 resharpening the grinding set, Maintenance – FRITSCH PULVERISETTE 2 User Manual

Page 34

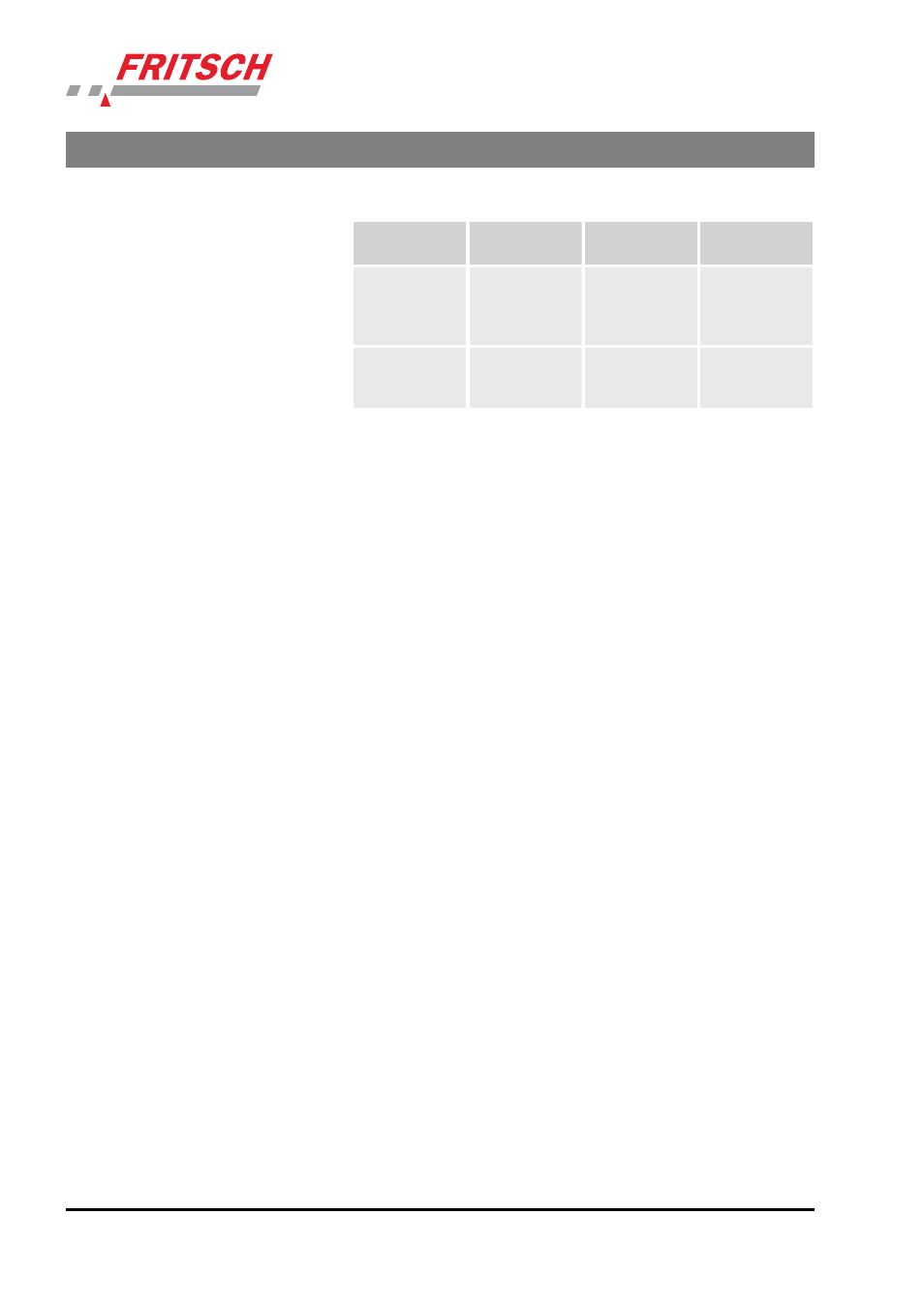

Functional part Task

Test

Maintenance

interval

Safety switch

Operator safety Does the mill

stop when the

hood is

opened?

Before each use

Ventilation slots Cooling system,

electronics

Proper function,

clean when

soiled

Twice a year

8.3 Resharpening the grinding set

After prolonged use, scratches or irregularities may appear on the sur-

faces of mortar and pestle, in which grinding stock can get stuck.

It is possible to resharpen the grinding mortar by filling it with approx.

20 g of carborundum (0.5 mm silicon carbide abrasive, grain 60) and

operating the laboratory mortar mill in normal grinding mode for a

½ hour. Downforce should be set to 5-10 daN, and the lateral pressure

should be set to the 1st ring.

Choose a longer duration for the sharpening process depending on the

depth of the scratches and the type of grinding set. Wet grinding with

added water is recommended. If it is not possible to obtain abrasives,

aluminium oxide (sintered corundum) of the same grain size (0.5 mm)

can be used as an alternative.

Maintenance

- 34 -