4 setting the grinding pressure, 2 positioning the pestle against the mortar wall, Using the device – FRITSCH PULVERISETTE 2 User Manual

Page 24

6.4 Setting the grinding pressure

NOTICE!

Before commissioning, it is necessary to adjust (zero posi-

tion) the pressure scale (see Ä Chapter 6.5.1 ‘Adjusting’

The contact pressure of the pestle against the wall and bottom of the

mortar must be adjusted in two directions.

The contact pressure is adjusted with the lid and latch closed.

6.4.1 Positioning the pestle against the bottom of the mortar

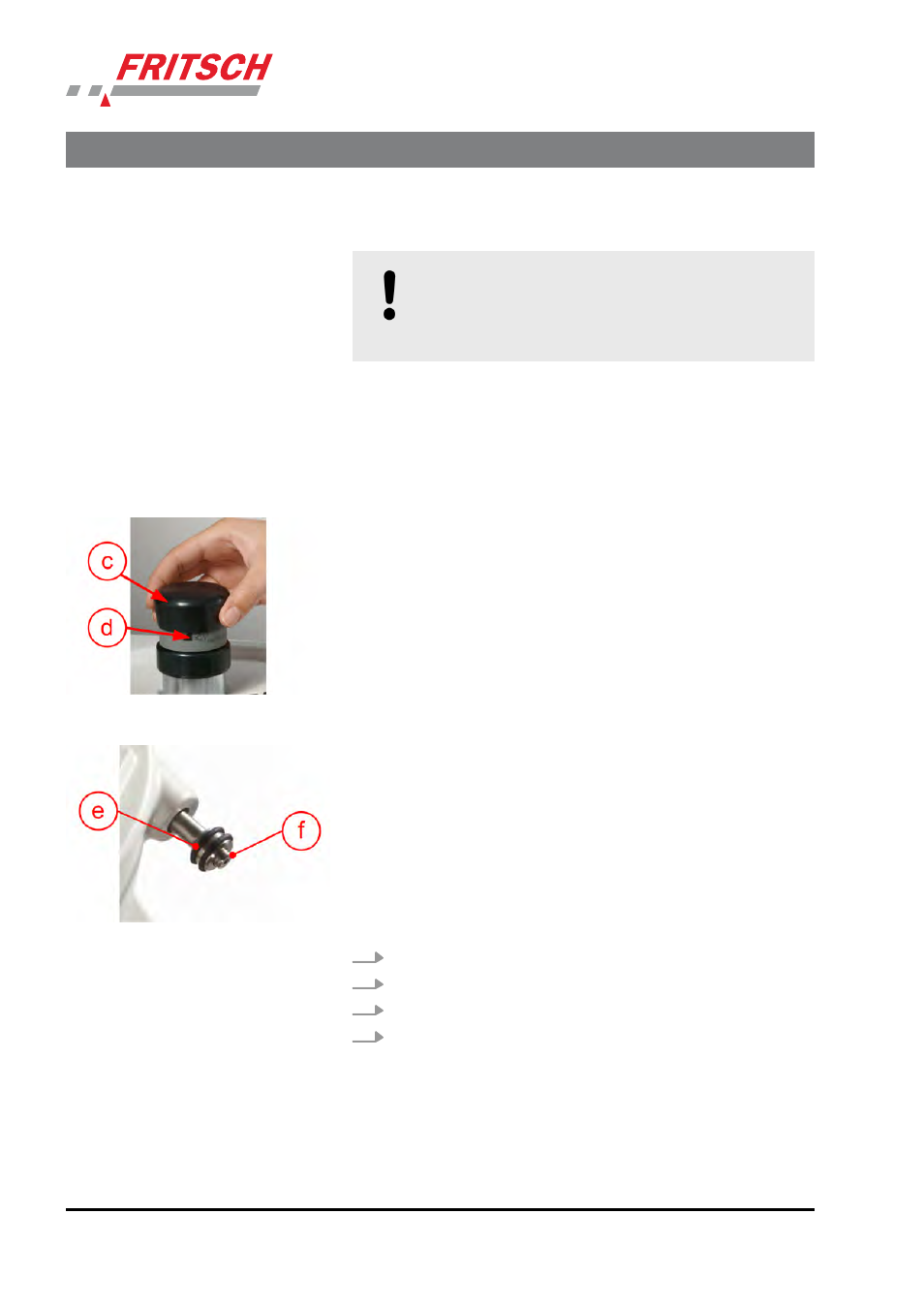

The desired contact pressure is set by turning the adjusting nut (c), and

its value is read on the scale (d). If the bottom edge of the black

adjusting nut (c) is above the Gap (mm) 0 display, the pestle is lifted from

the mortar according to the number (6 = 66 mm in the illustration). This

is only required for pre-crushing of coarse samples (see Ä Chapter 6.4.3

‘Pre‐crushing settings for coarse samples’ on page 25). For comminution,

the adjusting nut is usually set to a contact pressure [daN Downforce]

between 2.5 and 17.5 daN.

6.4.2 Positioning the pestle against the mortar wall

It is positioned radially in relation to the main rotation of the mortar. The

desired contact pressure is built up by turning the adjusting screw (e). To

do so, turn the screw (e) to the right until the display cylinder is visible

(f). The contact pressure can be read on the display cylinder (f). For most

applications, the lateral contact pressure is set so that the 1st ring or the

2nd ring is visible.

1.

Ring visible ~ 16.5 daN (kg)

2.

Ring visible ~ 20 daN (kg)

3.

Ring visible ~ 23.8 daN (kg)

4.

Ring visible ~ 27.3 daN (kg)

Read the grinding pressures as follows:

Using the device

- 24 -