Maintenance – FRITSCH PULVERISETTE 6 classic line User Manual

Page 52

Functional part

Task or description

Test

Maintenance interval

Drive motor

Permanent lubrication

Bearing clearance

Every 4,000 h or annually

V-belt

Motor planetary disc

Check belt tension

Disconnect the device from

the mains. Screw off the

(top) rear cover plate. The

belt must not slacken by

more than 10 mm when

pushed with your thumb.

Once a year

Fan, ventilation slots

Grinding chamber cooling

and electronics

Clean functional parts

when soiled

Twice a year

Grinding bowl tensioning

device, Safe-Lock (5)

Rubber of the pressure

piece and rubber disc in

the grinding bowl holder

Signs of use; replace if

pressed flat and no longer

elastic

After every 1,000 h

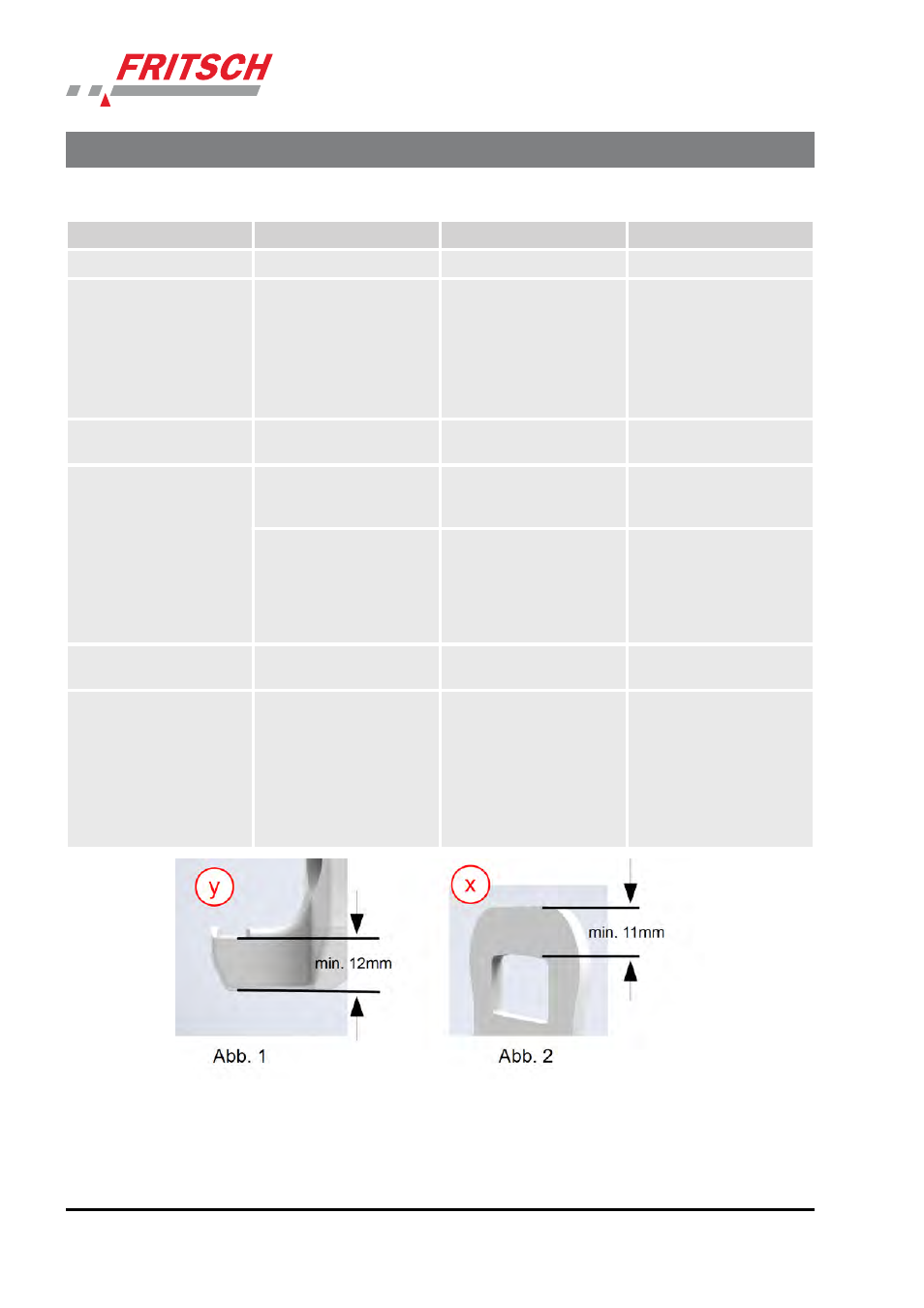

Indicated surfaces of Safe-

Lock are round

Original height, 12.5 mm

Minimum height, 12 mm

(y)

Safe-Lock has frequently

been tensioned too loosely

After every 200 h

If the height is under the

minimum height, the corre-

sponding part has to be

replaced.

Grinding bowl lid seal

Seal the grinding bowl

Replace seal if dirt has

penetrated

After every 100 h

Grinding bowl holder (8)

Keep tension

Original height, 14 mm

Minimum measurement at

grinding bowl holder, 11

mm (x)

Twice a year; this minimum

measurement may have to

be checked more often

depending on use.

If the height is under the

minimum height, the corre-

sponding part has to be

replaced.

Maintenance

- 52 -