9 maintenance, Maintenance, 9maintenance – FRITSCH PULVERISETTE 6 classic line User Manual

Page 51

9

Maintenance

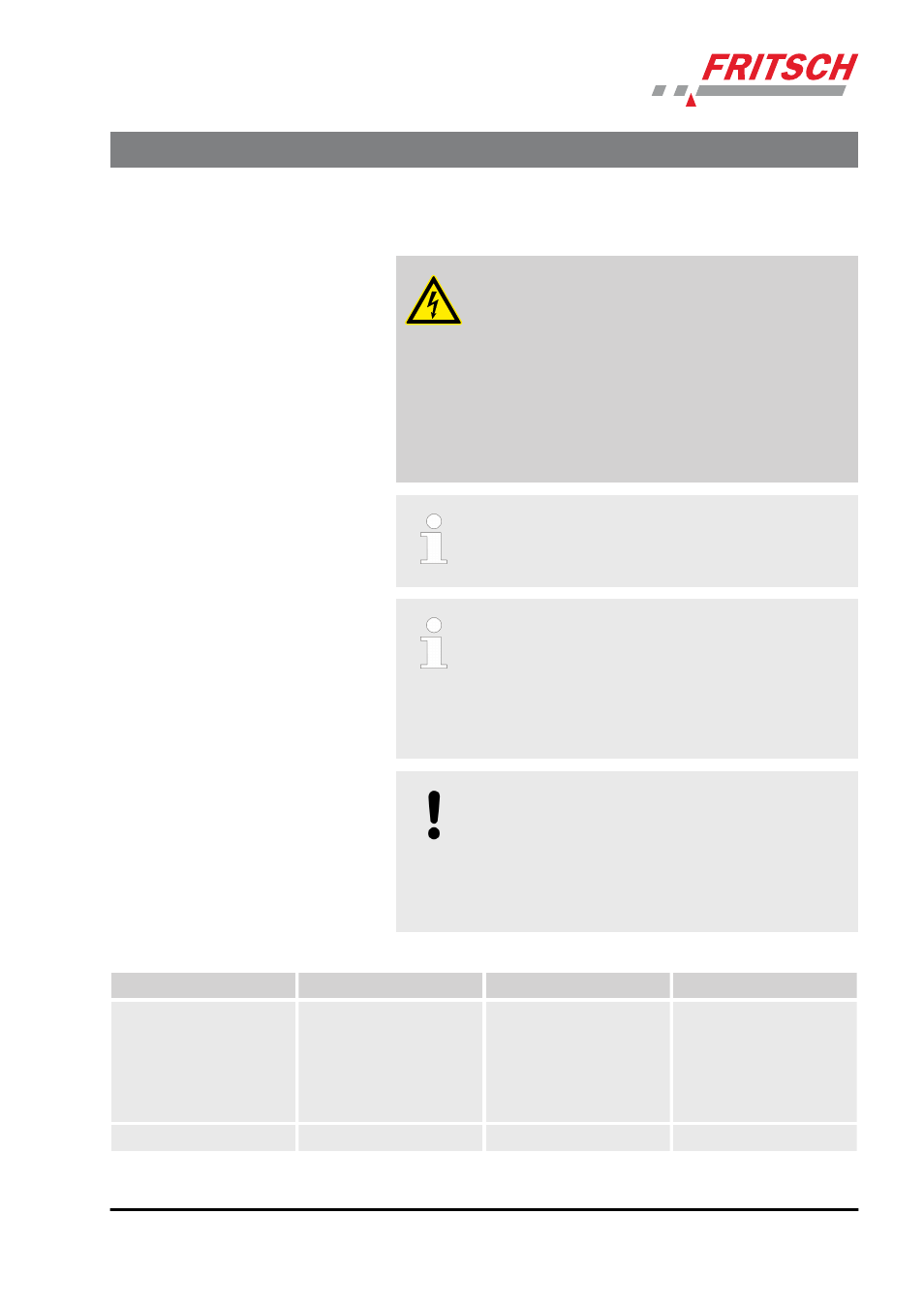

DANGER!

Mains voltage

– Before beginning with maintenance work, unplug the

mains plug and protect the device against being unin-

tentionally switched back on again!

– Indicate maintenance work with warning signs.

– Maintenance work may only be performed by special-

ised personnel.

– Put safety equipment back into operation after mainte-

nance or repair work.

We recommend keeping a safety logbook Ä Chapter 15

‘Safety logbook’ on page 62, where all work (maintenance,

repairs......) performed on the device is entered.

– The most important element of maintenance is regular

cleaning:

– When cleaning the complete device, adhere to the

guidelines of the Accident Prevention Regulation (BGV

A3) ‐ especially if the device has been set up in a dusty

environment or if the processed source material pro‐

duces dust.

NOTICE!

Safe-lock - clamping systems might lose their tension force

over time of usage. To watch the right tension force of each

Safe-lock - clamping system Fritsch GmbH stipulates a

scheduled maintenance interval of one year. Please send

back all Safe-lock - clamping systems for regular checks to

Fritsch GmbH. This service is liable to pay the costs.

Functional part

Task or description

Test

Maintenance interval

Safety lock

Hood lock (7)

Is the closed hood (3)

locked in place when the

main switch is off?

If this test is failed, do not

continue to work until the

fault has been rectified.

Before each use

Rotating bearings

Permanent lubrication

Bearing clearance

Every 2,000 h or annually

Maintenance

- 51 -