Cub Cadet 190-209-100 User Manual

Page 18

18

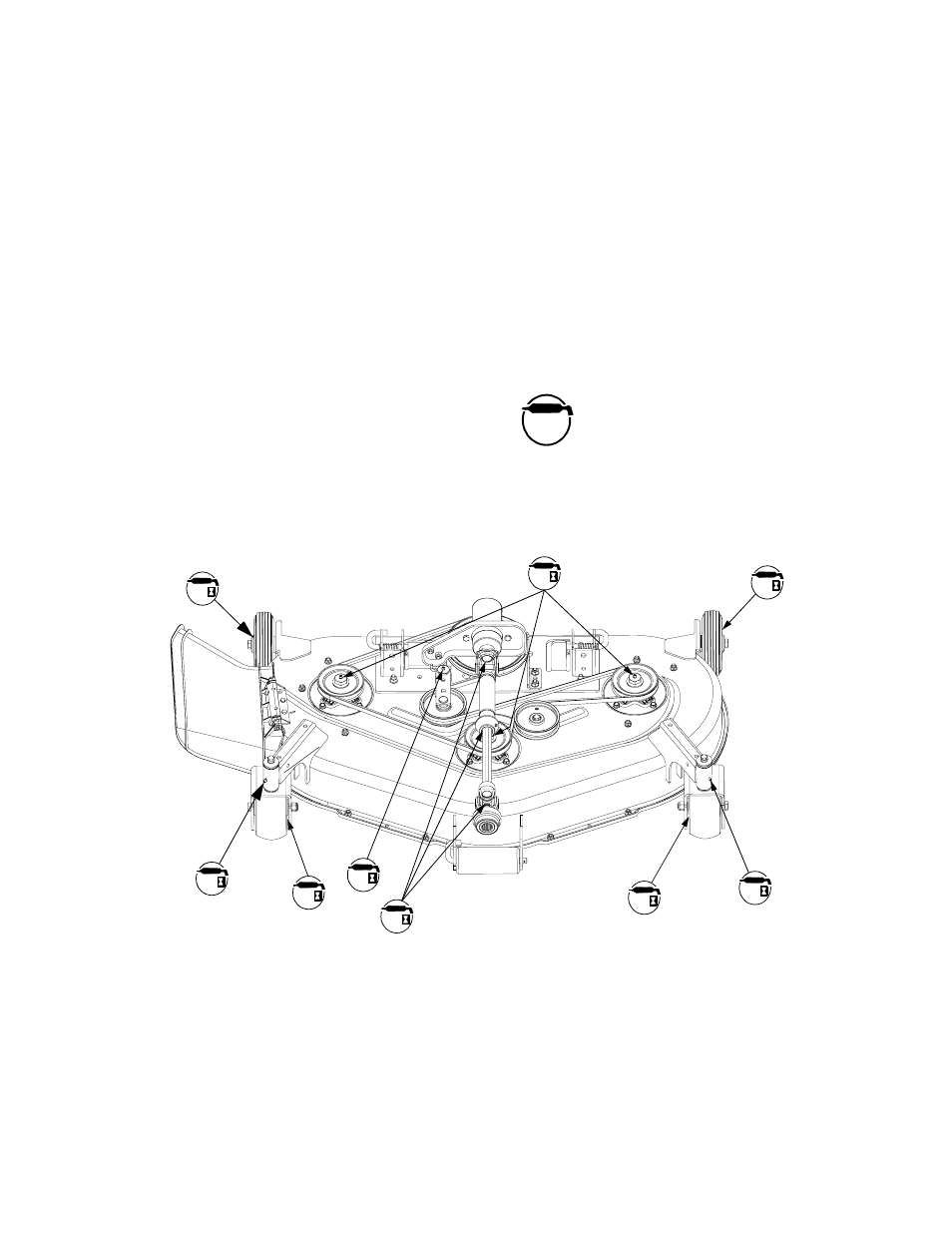

SECTION V. LUBRICATION GUIDE

The life of any machine depends upon the care it is given. Proper lubrication is a very important part

of that care.

NOTE: We do not recommend the use of a pressure

washer or garden hose to clean your unit. They may

cause damage to electrical components; spindles;

pulleys; bearings; or the engine. The use of water will

result in shortened life and reduce serviceability.

Be certain that all lubrication fittings are assembled in

place, using Figure 31 as a guide.

Always lubricate the deck thoroughly before taking it to

the field. Use a pressure lubricating gun.

Be sure all fittings are free from dirt and paint so the

lubricant is certain to enter the bearing.

Miscellaneous working parts not provided with

lubrication fittings should be oiled regularly with a good

grade of lubricating oil.

Lubricant is cheap. Use plenty of it. Worn parts can be

expensive to replace.

Keep your supply of lubricating oil and grease stored in

clean containers, and covered to protect from dust and

dirt.

Keep the lubricating gun nozzle clean and wipe dirt

from the grease fittings before lubricating.

The symbol in the illustration indicates the grease gun

method of application and the hourly intervals to apply

the lubricant.

Use a pressure lubricating gun

and apply 251H EP grease (or

equivalent No. 2 multi-purpose

lithium grease) sufficient to flush

out the old grease and dirt. Lubri-

cate at the hourly intervals indicat-

ed on the symbols.

Figure 31

10

1

10

2

50

3

50

6

50

50

4

4

50

50

5

5

50

6

1.

2.

3.

4.

5.

Deck Spindles — Every 10 Hours of Operation

Idler Arm — Every 10 Hours of Operation

Deck Drive Shaft — Every 50 Hours of Operation

Caster Wheels — Every 50 Hours of Operation

Front Caster Spindles — Every 50 Hours of Operation

Rear Gauge Wheels — Every 50 Hours of Operation

6.