Tsn (cam-over wrench) operating instructions – Checkline TSN User Manual

Page 2

TSN (Cam-Over Wrench) Operating Instructions

Rev 2.0 (March 20, 2008)

TSN Maintenance Schedule

Expected Tool Life

With normal use – 100,000 operations

Initial Settling in Period

1500 operations, during which frequent calibration checks are recommended.

Period between Resetting of Torque

5000 operations (as recommended in BS EN 26789:1994). It is acknowledged that some TSN tools achieve 5000 operations

in a relatively short period of time. Under these circumstances the User may decide, with the benefit of their experience, to

increase the period between calibration checks.

Routine Maintenance

After 100,000 operations, strip, clean & re-grease the Spindle, Cam & Roller. Any worn components should be replaced.

Note: Any tool that is dismantled during its life must be re-lubricated in accordance with the Mountz recommendations. Do not

clean tools by immersing them in solvent, as this will destroy the internal lubrication and cause failure of the tool.

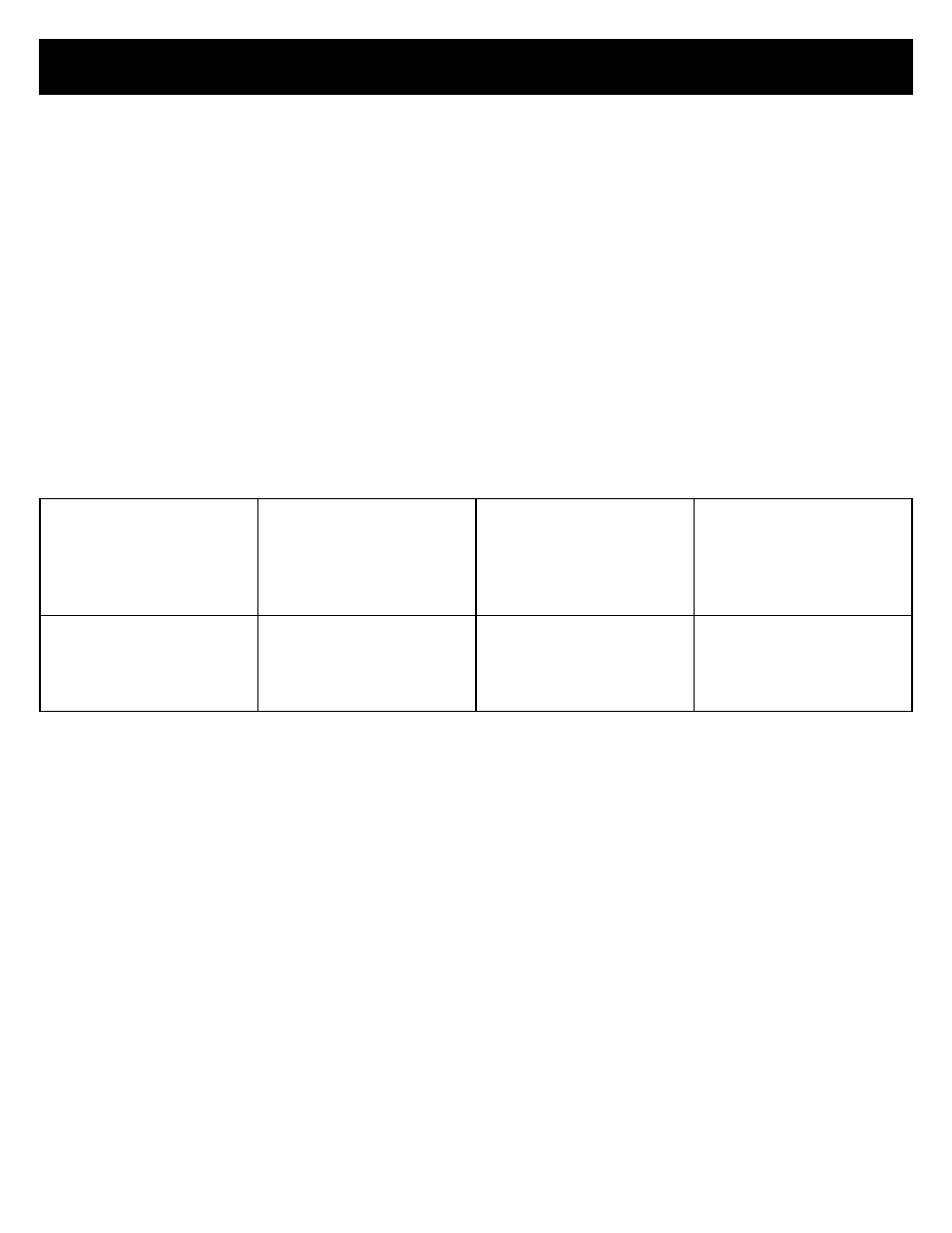

Tool Lubrication Chart for TSN

TSN Cam/Spindle Replacement Procedure - Overview:

This procedure has been prepared in response to requests from authorized Mountz Distributors who wish to Service and

Replace components in the head assembly of TSN wrenches.

Tools and Materials:

- Rear bearing removal tool - to suit model of TSN being serviced

- Rear bearing insertion mandrel - to suit model of TSN being serviced

- Normal Workshop tools

- Replacement parts as necessary

- Anti-scuffing paste - ROCOL ASP recommended

- Light machine oil

Procedure

1. The external parts of the TSN should be cleaned. The dust cap at grip end of handle removed and the torque adjustment

mechanism slackened off just to the point where the square drive of the TSN can freely rotate in both directions. This

indicates that the roller is no longer in engagement with the cam. Do not slacken the adjustment screw further than this

point as the roller will become disengaged from the roller guide and may be difficult to relocate.

2. Remove the Spirolox retaining ring from the underside of the head assembly.

3. Gentle tapping of the head assembly against a wooden block (as per sketch) will eject the cam/spindle assembly complete

with cover plate and front bearing from the TSN head. This may also cause the spindle and pawls to be ejected from the

cam. If this occurs take care not to lose the pawls or pawl springs.

Gulf

Gulflex Moly

Temp Range

-1 to 120 C

or equivalent

Silicon Grease

RS 555-083

Temp Range

-50 to + 200 C

Shell Tonna 32

Lubricating Oil

Total

Drosera 68

Rocol ASP

Anti-Scuffing paste

Life Time Lubrication

Max Temp 450 C

General - except

Roller & Cam

Ratchet

“O” Rings

Ratchet

Roller & Cam