Checkline MK User Manual

Page 3

-3-

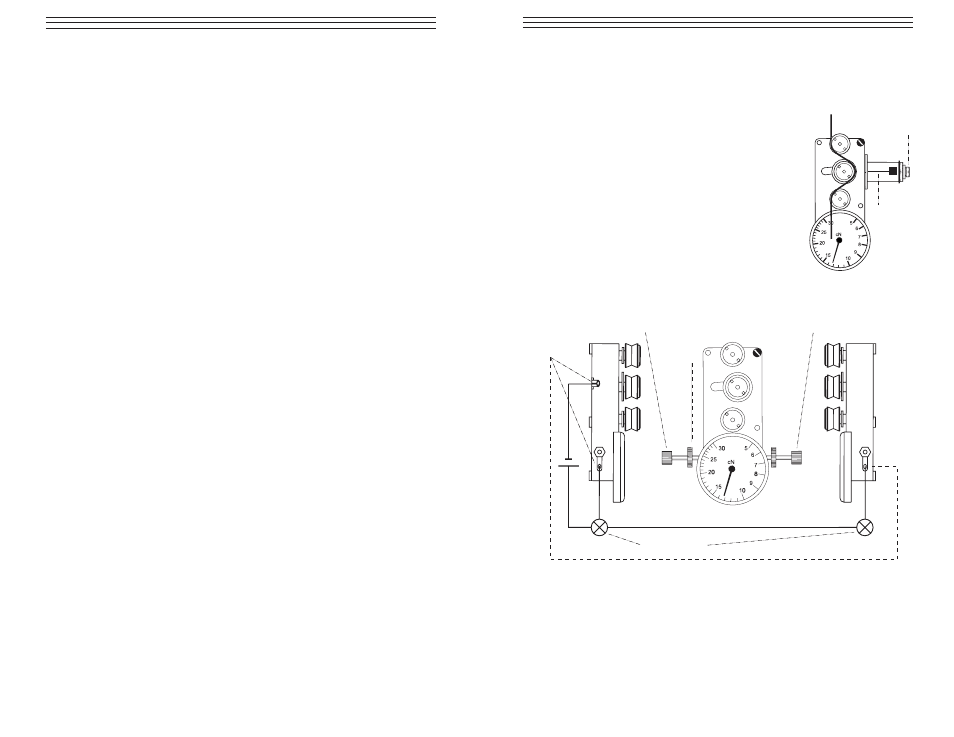

To set the Dashpot

1. Turn the setscrew clockwise as far as it will go

(screw is protected against overturning). The

dashpot is now at its maximum setting.

2. Screw the setscrew out again counter-clockwise

until the desired damping factor for the scale

pointer is achieved.

Note: A change in the damping factor is only

possible within the first three counterclockwise

revolutions of the setscrew.

3. Turn the setscrew clockwise to increase

damping.

4. Turn the setscrew counterclockwise to reduce

damping.

1.4 Min/Max Contacts (Optional Accessory Code D)

Your MK tensionmeter can be factory-equipped with Min/Max tension-

detecting contacts which allow you to monitor the tolerance limits for the

measured tension. We recommend application of the tension-detecting screw

contacts in case of automated production sequences. These factory-installed

Setscrew

Dashpot

Locknuts

MIn Setscrew

MAX Setscrew

Soldering tag

for cable

connection

max. 24 V / 2 W

-6-

3.0 S

ERVICE AND

M

AINTENANCE

The tension meter is easy to maintain. Depending on operating time and load, the

tension meter should be checked according to the locally valid regulations and

conditions.

Other testing methods as can cause different measuring readings.

3.1 Rollers

You should regularly inspect the rollers to assure that they are running easi-

ly and smoothly. You can replace the rollers yourself, as necessary. When

ordering spare rollers, please indicate the tension meter model and the serial

number (on the rear side of the tension meter).

Ordering of spare rollers

Model: MK-12 (on the right side of the tension meter)

Serial number: 300 -888888 (on the right side of the tension meter)

Standard rollers: Order number R12013

3.2 Cleaning

For cleaning the unit, do not use any AGGRESSIVE SOLVENTS such as

trichloroethylene or similar chemicals. NO WARRANTY OR LIABILITY

shall be accepted for damage resulting from improper cleaning.

3.3 Verification Intervals

The question of finding the right frequency of calibration accuracy

verification depends on several different factors:

• Operating time and load of the SCHMIDT tension meter

• Tolerance band defined by the customer

• Changes of the tolerance band compared to previous verifications of

calibration

Therefore, the interval between verifications must be determined by the

user`s Quality Assurance Department based on the user`s experience.

Assuming normal operating time and load as well as careful handling of the

tension meter, we recommend a verification interval of 1 year.