Checkline MK User Manual

Page 2

-2-

1.0 O

PERATION

1.1 Fastening the MK Tensionmeter

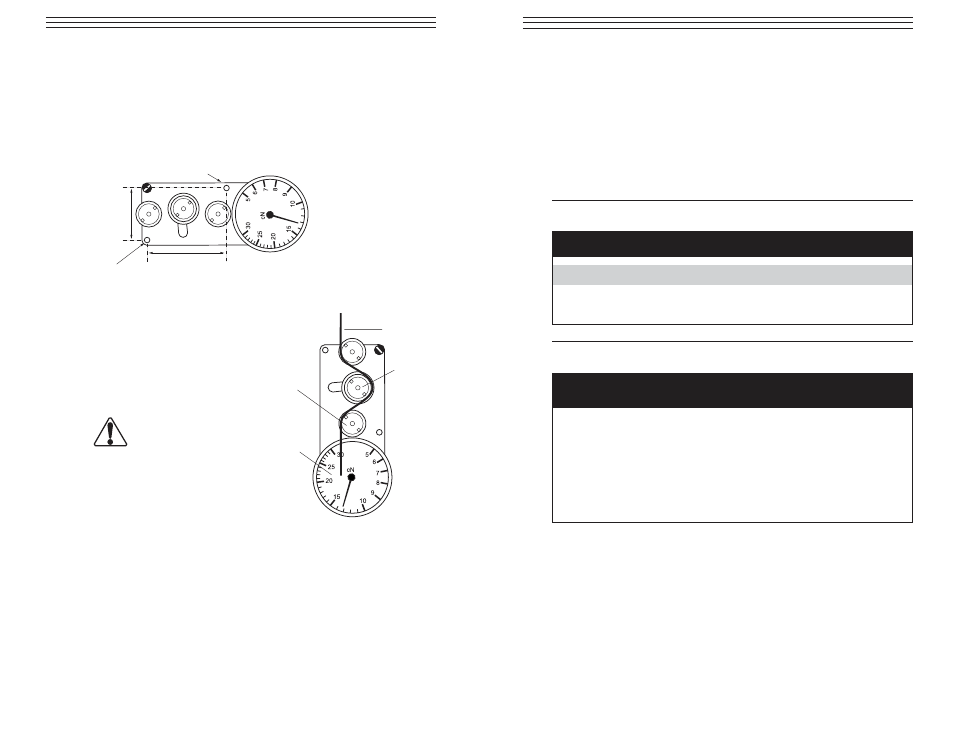

Two mounting holes are provided for fastening the tensionmeter on site. For

the mounting hole dimension, see the figure below.

1.2 Inserting the material to be measured

Thread the material to be measured

carefully through the measuring roller

and roller guides as shown in the figure

at right. it is important to ensure that

the material runs smoothly through

the roller guides and the measuring roller.

To avoid damage, do

not move the center

roller using force.

You can now read the measured

tension on the scale.

1.3 Air

Damping (Optional Accessory code A)

The measuring system of the MK can be factory-equipped with a dashpot.

This dashpot makes it possible to absorb approximately 50% of the pointer

oscillations. We recommend application of the dashpot in the case of high

tension fluctuations (spooling or winding). The setting of the dashpot has to

be tuned to the local conditions by experimenting.

30 mm

46 mm

Mounting Hole

diameter 3.1 mm

Mounting Hole

diameter 3.1 mm

Measured

material

Measuring

roller

Scale

Roller

guides

CAUTION

4.0 S

PECIFICATIONS

Calibration:

According to SCHMIDT factory procedure

Accuracy:

± 1% full scale (FS) or ± 1 graduation on scale

Scale diameter:

43 mm

Temperature range:

10 – 45°C

Air humidity:

85% RH, max.

Housing material:

Plastic (Makrolon)

Housing dimensions:

96mm x 44mm x 2 mm (L x W x H)

Weight, net (gross):

approx. 80 g (200 g)

4.1 Roller Guides

-7-

V-grooved

Line Speed M/min max.

Roller Material

Standard 1000

Hardcoated

aluminum

Code T

1000

Plastic (POM) black

Code W

1000

Nickel-plated steel

Type

Measuring range cN

**Factory Calibration Material

MK-12

12 – 3

Filament: 25 tex

MK-20

0

5 – 20

Filament: 25 tex

MK-30

0

5 – 30

Filament: 25 tex

MK-50

10 – 50

PA: 0.12mm Ø

MK-100 10

–100

PA: 0.12mm

Ø

MK-250

20 – 250

PA: 0.12mm Ø

MK-300

20 – 300

PA: 0.20mm Ø

MK-400

50 – 400

PA: 0.20mm Ø

4.2 Available Models

** Suitable for 95% of applications. PA = Polyamide Monofilament If the

material to be measured differs significantly from the SCHMIDT calibration

material in diameter, rigidity, shape, etc., we recommend calibration using

customer material. For this purpose, a material sample of about 5 m should be

supplied. International unit for tension force:1 cN = 1.02 g = 0.01 N