Checkline BTM-400PLUS User Manual

Page 3

3

2.0 I

NTRODUCTION

A belt drive achieves its maximum lifetime and efficiency when:

1. It is properly configured and rated for the application.

2. The belt is tensioned to the manufacturer’s recommended tension.

3. The pulleys are perfectly aligned.

The CHECK•LINE

®

BTM-400PLUS Belt Tension Meter affords the user an easy,

reliable method for accurately measuring the tension in a belt system at standstill.

3.0 O

PERATING

P

RINCIPLE

When the Free Span* of a belt is plucked, tapped or struck, it will vibrate at a

frequency known as its “natural” frequency, the value of which depends on the

existing tension in and the total mass of the Free Belt Span, according to the

following relationship:

f = T/4dL

2

or T = 4dL

2

f

2

where:

f = Natural frequency of the Free Belt Span (Hz)

T = Tension in belt (N or lbf)

d = Belt density (kg/m or lb/ft)

L* = Length of the Free Belt Span (m or ft), which vibrates when struck.

* For definition of Free Span, refer to 4.2 and Figure 2.

The d and L parameters are fixed in the design of the belt, while the “natural”

frequency (f) varies with the applied Belt Tension (T). The BTM-400PLUS picks

up the vibration frequency of the Free Belt Span and displays it, or the corresponding

belt tension, on the instrument’s LCD display panel.

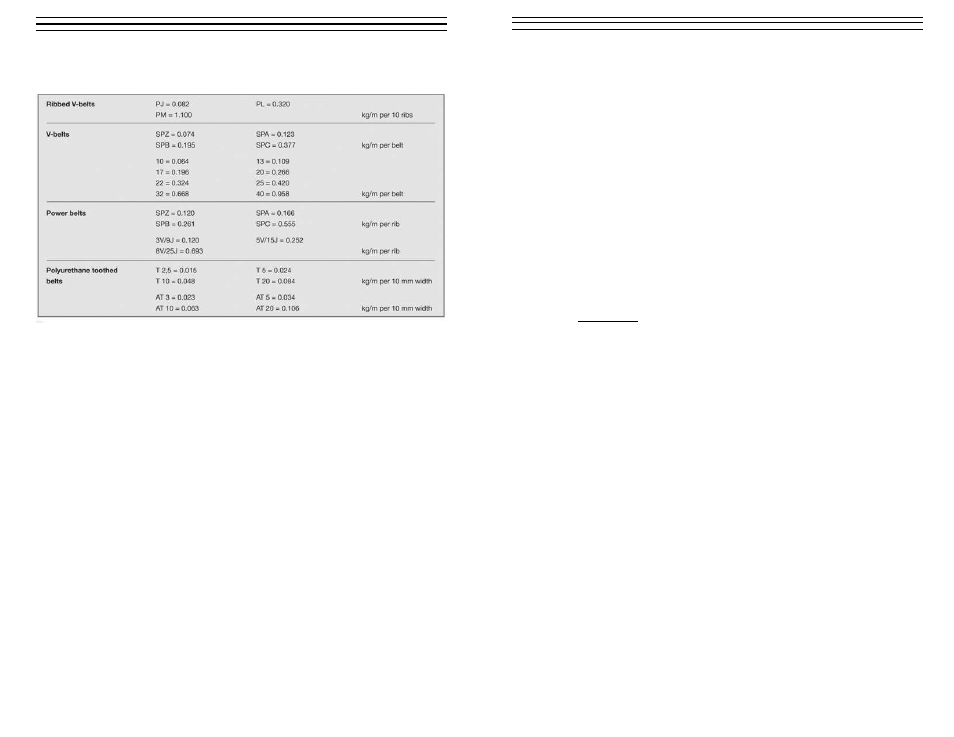

10.0 T

YPICAL

B

ELT

D

ENSITIES

10

√