Checkline SY User Manual

Page 4

4

5

3 .0 P

REPARI N G

SY T

EN SI OM ET ER

C

ALI BRAT I ON

C

H ART S

/C

U RV ES

3.1 Material

Required

1. Test Span Sample of 14-ft (minimum) of the installed cable, where long

cables are involved. Where installed cables are less than 14-feet long,

use a test span equal to the length of the cable.

NOTE: Application spans of less than 14-feet, great stiffness and/or

large diameter may not be measurable. Please inquire.

2. Turnbuckle, winch or hydraulic tensioning system of sufficient load capacity

for the application.

3. An in-line tension-reading device, such as a certified dynamometer or load

cell with indicator.

4. Rigid attachment structure, to withstand the full tensile loads.

5. Attachment hardware for all cable ends and devices.

3.2 Procedure

1. Set up the load cell, or other readout device, so that its indicator reads “0”.

2. The pointer of the Tensiometer dial indicator should read “0”. If not, rotate

the outer bezel of the indicator until it does read “0”.

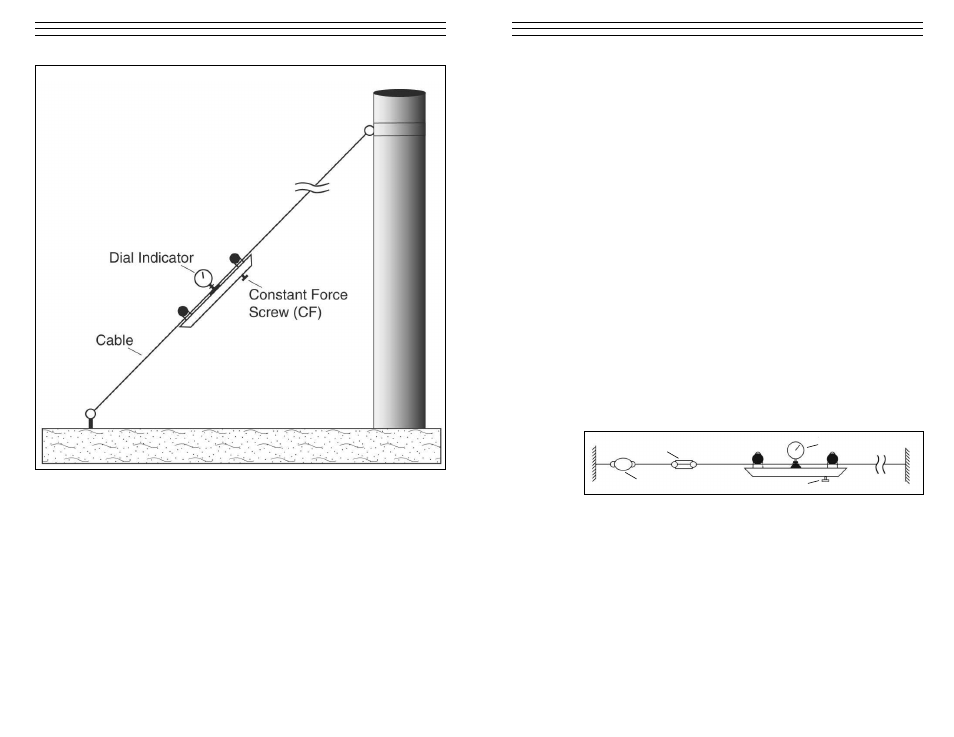

3. Set up the test cable sample, load-applying device and the inline tension

read-out device, as indicated in Figure 2., SY Tensiometer Calibration Setup,

below.

4. Before hanging the SY Tensiometer being calibrated on the cable, lower the

middle roller to provide clearance between the dial indicator shoe and the

middle roller for the test cable, by turning the knurled CF screws head

clockwise (CW) until the middle roller retracts sufficiently to provide the

needed clearance.

5. Hang or hold the SY Tensiometer so that the test cable passes under

the outer rollers and over the middle roller. The inline indicator will

show a minimum tension, resulting from the weight of the cable and

the tensiometer itself.

Dial Indicator

Constant Force Screw (CF)

Figure 2. SY Tensiometer Calibration Setup

Dynamometer

Turnbuckle

Figure 1. SY Tensiometer Measuring Setup