Checkline EDM User Manual

Page 3

3

2.0 O

VERVIEW

2.1 Operating

Elements

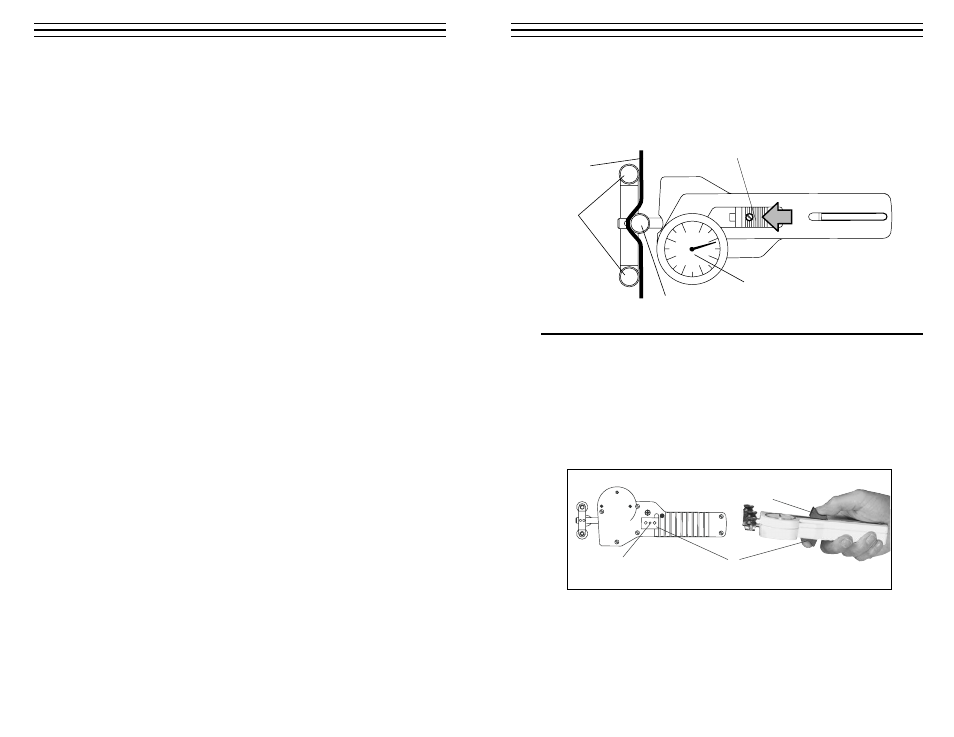

2.2 Mounting Special Finger Support

Whenever useful and necessary, the tension meter is supplied with a special

finger support. We recommend mounting the finger support when measuring

high tension to reduce the necessary effort to move the outer rollers with the

Thumbpiece on the front of the tension meter and facilitate acquisition of the

wire to be measured. Place the special finger support in the recess located on the

rear side of the tension meter and fasten it with the finger support screw.

Thumb piece

Measuring

roller

Process

material

Scale

Guide

rollers

❙ ✁✂ ✄

al finger support

Finger support screw

Thumb piece

6

4.1 Frequency Of Calibration Verification

Frequency of calibration accuracy verification depends on many factors. These

include frequency and extent of tension overloads, operating speeds, length of

operating times, environment, care in handling, etc. Such determination is best

made by the user’s Quality Assurance Department based on the user's experience.

However, a quick calibration check near the anticipated process tension levels

should be done to confirm the integrity of the instrument, as follows:

1. At the beginning of each work session.

2. Every time a unit is dropped.

3. Whenever process readings seem to be out of tolerance for no apparent

reason.

The quick check can be made with a simple load stand, as shown section 4.2,

using a sample of the process material and weights that are close to the tensions

encountered in the process. Be sure to move the tension meter up and down

slowly to simulate the motion of the running process material. This will check

the condition of the guide roller ball bearings and remove any inertia effect of

the movement. Readings that change with this motion reversal may indicate the

possibility of a guide roller ball bearing problem.

In the case of wire, which might be slightly deformed by the action of the

3- roller system during static measurement, always move to a fresh portion

of the wire each time a measurement is made. (In production, the instrument

always “sees” a fresh portion.)

4.2 NIST Calibration

While all DX2-EDM instruments are furnished with a Calibration Certificate

which certifies that they have been calibrated in accordance with factory

procedures and were found to meet all published accuracy specifications,

such calibrations do not fulfill ISO-9000 requirements since no record of

measured values are kept or are submitted. Where ISO-9000 requirements

are to be met, NIST calibration is optionally available but must be specified

at time of order placement or after repair.