Checkline EDM User Manual

Page 2

2

1.0 I

NTRODUCTION

DX2-EDM Tension Meters are hand-held, mechanical instruments which

accurately measure the running as well as static tensions at the wire used

in wire EDM machines.

The DX2-EDM employs the 3-roller principle for tension measurement where

the outer two reference guide rollers remain fixed during measurement to establish a

wrap angle over the middle sensing roller. The middle roller, acting against an internal

calibrating spring, is displaced relative to the line tension. This displacement is con-

verted to rotary motion to turn a pointer on a scale to give a reading in grams tension.

1.1 Complete

Kit

(included in shipment)

• Tension meter

• Special finger support

• Operating instructions

• Carrying case

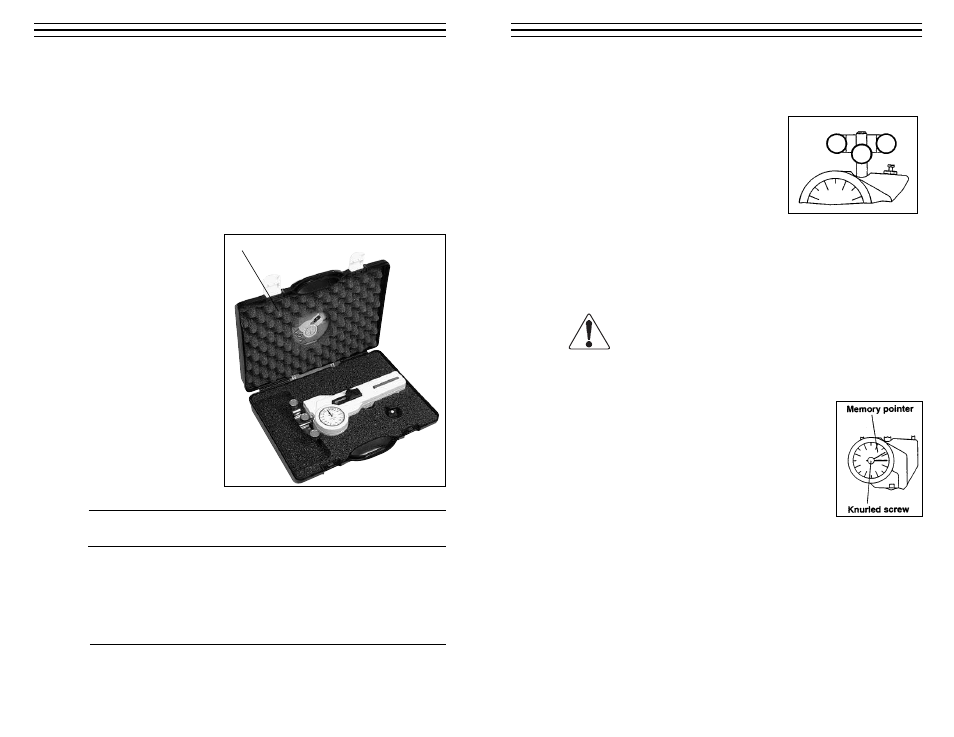

1.2 Unpacking

Unpack the tension meter

and inspect it for any

shipping damage. Notices

of defect must be filed

within 10 days of receipt

of the tension meter.

1.3 Model

Ranges

Tension Roller

Calibration

Ranges (cN)

Distance (c:c) mm

Material

050 - 2000

0

75

PA: 0.30 mmØ

150 - 2200

0

75

PA: 0.30 mmØ

100 - 3000

0

75 PA: 0.30 mmØ

200 - 4000

100

PA: 0.40 mmØ

Operating Instructions behind foam pad.

7

5.0 O

PTIONS

5.1 Air Dashpot Damping

DX2-EDM Tension Meters incorporate a

moderate amount of movement damping to

smooth out some high frequency tension

fluctuation. However, where process fluctuations

result in rapid pointer swings which make it

difficult or near impossible to read the scale,

an optionally-available Air Dashpot Damping

mechanism can be provided to slow down the

pointer swings to permit a reading. In setting up the mechanism, it is best to set

the damping rate just to the point where a readable pointer results with minimal

pointer swings. The amount of damping is set by turning the small slotted screw

or hex-head screw of the damping assembly located near the guide-roller mount-

ing bracket. The Air Dashpot must be installed at time of original manufacture.

It cannot be added later.

5.2 Memory Pointer

The optional Memory Pointer assembly retains the highest

reading obtained during a measuring period. Before using

the instrument, rotate the knurled pointer knob clockwise

until the “memory” pointer tab contacts the measuring

pointer at zero. During operation and after instrument

removal, the trailing “memory” pointer will hold the

maximum reading until reset with the pointer knob.

CAUTION

Do not set the damping rate too high as this will

damage the instrument.