Checkline KXB User Manual

Page 7

6

7

5.0 CALIBRATION NOTES

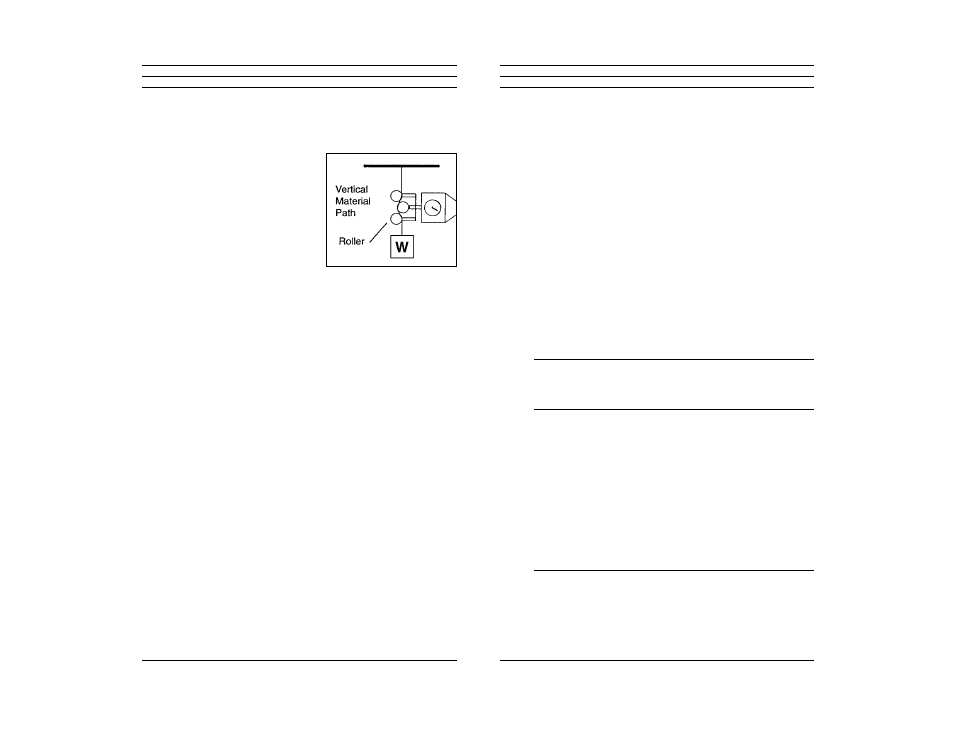

The calibration process

involves hanging laboratory

weights from a fixed point,

engaging the vertical line

material which holds the

weights with the tension

meter 3-roller system, mark-

ing a blank dial face where

the scale pointer comes to

rest for each weight used, dividing the spaces between

load “reading” marks and finish marking and number-

ing to show calibration marks and “readings” on the

dial face.

The procedure requires specialized skills and the

following material:

1. A load stand to simulate the setup shown here.

2. A set of precision laboratory weights to cover the

tension range of the instrument.

3. Factory “standard” nylon monofilaments as shown

in the Table on page 7.

4. A Calibration Kit which includes an Alignment

Plate and two (2) special metric wrenches.

A full, detailed calibration procedure is available upon

request.

5.1 Calibration with Factory Standard Filaments

All DX2 and DXX Tension Meters are calibrated with

laboratory weights suspended from factory Standard

nylon monofilament sizes, as noted in the table below.

Any difference in process material size and rigidity

from the Standard materials may result in some error.

For over 95% of applications, the error is not signifi-

cant and can be ignored since readings are generally

treated as production setup values or are used for

comparative purposes. In those cases where highest

accuracy is required, a correction chart showing

Readings vs. Actual Load should be made up by the

user or “Special” calibration should be specified when

an order is placed.

Standard Calibration Monofilament Sizes

Mono-

Range filament

Model

Model (Grams)

Diam.

(mm)

DX2-5 DXX-5

5-50

1000 denier

or 0.15 max.

DX2-12

DXX-12

10-120

0.20

DX2-20

DXX-20

10-200

0.20

DX2-40

DXX-40

10-400

0.25

DX2-SP

DXX-SP

20-1000

0.30

DX2-EX

DXX-EX

100-1000

0.30

DX2-200

DXX-200

200-2000

0.50

DX2-500

DXX-500

400-5000

0.80

DX2-1K

DXX-1K

2-10 kg

1.00

DX2-2K

DXX-2K

5-20 kg

1.20