Checkline DX2 User Manual

Page 4

4

3.0 Thickness Compensation

The 3-roller system for tension measurement

relies on the displacement of the middle roller to

give an indication of line tension. As the material

diameter or thickness changes, there will be

a change in tension reading, even though line

tension has not changed. To offset this effect,

high-range instruments (1000 grams and

higher) are usually furnished with a Thickness

Compensator, as shown here. To determine

whether the Compensator needs to be used for

a specific application, take readings with and

without the process sample in the Compensator

using a hanging weight approximately equal to

the process operating tension.

To set up the Thickness Compensator, proceed as follows:

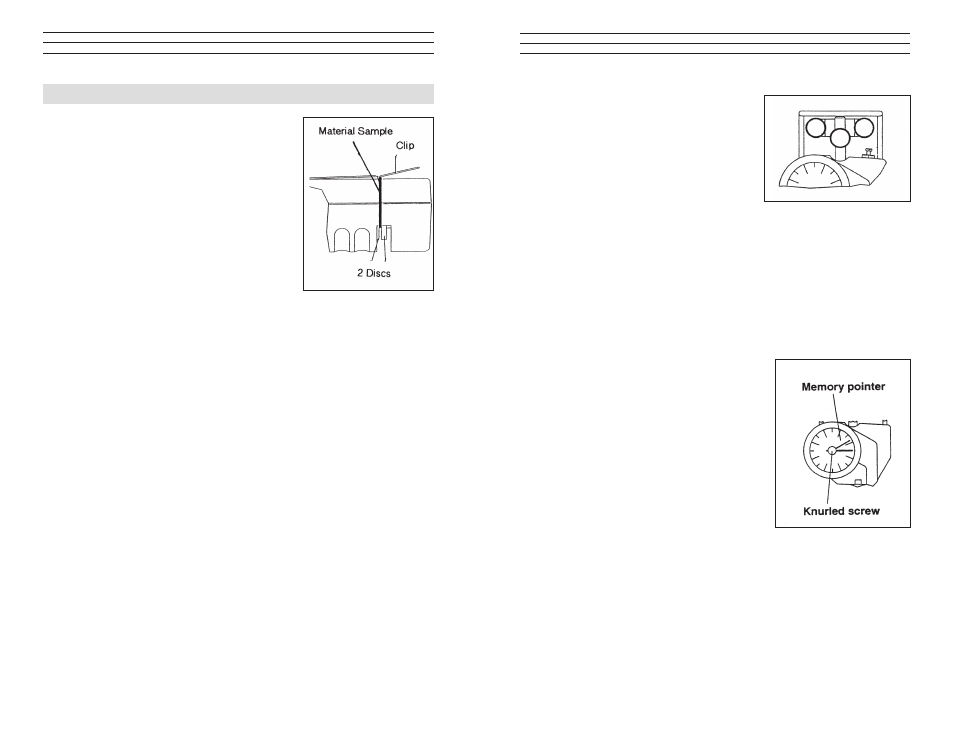

1. With the Thumb Piece pushed forward and held, pass a sample of the process

material through the opening at the instrument end, as pictured here,

making sure it lies between the two visible disc-like anvil surfaces.

2. Allow the Thumb Piece to SLOWLY return to its original position.

caUTiON: Do not let the Thumb Piece snap back as this may affect

calibration and also damage the instrument.

3. Secure the process sample ends under the spring clip provided or with some

tape. The instrument is now ready to use.

9

6.3 air dashpot damping

DX2 Tension Meters incorporate a moderate

amount of movement damping to smooth

out some high frequency tension fluctuation.

However, where process fluctuations result

in rapid pointer swings which make it difficult

or near impossible to read the scale, an

optionally-available Air Dashpot Damping

mechanism can be provided to slow down the

pointer swings to permit a reading. In setting up the mechanism, it is best to set

the damping rate just to the point where a readable pointer results with minimal

pointer swings. The amount of damping is set by turning the small slotted screw or

hex-head screw of the damping assembly located near the guide-roller mounting

bracket. The Air Dashpot must be installed at time of original manufacture. It

cannot be added later.

caUTiON: Do not set damping rate too high as this will damage the

movement.

6.4 memory pointer

The optional Memory Pointer assembly retains

the highest reading obtained during a measuring

period. Before using the instrument, rotate

the knurled pointer knob clockwise until the

“memory” pointer tab contacts the measuring

pointer at zero. During operation and after

instrument removal, the trailing “memory”

pointer will hold the maximum reading until

reset with the pointer knob.