Checkline HP-Textile-Durometer User Manual

Page 4

-4-

3.0 V

ERIFYING

C

ALIBRAION

3.1 Textile Models (HP-2.5, HP-2.5F, HP-5, HP-5F, HP-10, HP-10F)

The Textile Durometers utilize a 0-100 units scale. The units have not formal

engineering classification and are not related to a specific Shore value or

other known value. These Textile Durometers are designed to obtain objective

comparative values that are effective for classifying the end-product quality.

Therefore, there are no standards that can be used to compare against and it is

for this reason that an NIST-Traceable Calibration Certification can not be

performed.

You can however test that the gauge is functional and un-damaged by press-

ing the flat-bottomed models ("-F" models) against a smooth surface (such as

glass or marble). When fully pressed down, the dial should perform one com-

plete rotation and go back to "0". When released, it should un-coil, and return

to "0" as well. If not, please contact the factory immediately.

On model with a concave base (for measurement on small bobbins or cones),

you can perform a similar "full scale" test using the optional Zero Test Block

(part number HP-TB).

1. Press the Textile Durometer

down on the test plate, which is

available as an accessory and

can be ordered under item

number HP-TB (see Fig. 1).

Do not move the spring-loaded

outer ring.

2. The scale pointer should make

one full turn on the scale, from

zero to zero, when you press

down on the instrument. If it

does not, contact Electromatic

for assistance.

NOTE:

Do not loosen the holding screws of the movement under any

circumstances. Loosening these screws may alter the calibration of the

instrument.

Scale

Spring-loaded

outer ring

Color marking

Holding screws

Test block

Part No.: HP-TB

Fig. 1

3.2 Shore Models (HPSA, HPSB, HPSC, HPSD, HPSO, HPDO)

The Shore Durometers model are calibrated against industry standards as

specified in ASTM, DIN and JIS Test Procedures. Calibrated Test Samples

CAN NOT BE USED for verification of the calibration, as these test samples

are subject to change due to temperature, sunlight and other ambient condi-

tions. Certification of the calibration is normally done at test facilities that

can independent test the internal spring forces of the Durometer and check

the travel/reading accuracy of the dial indicator.

Contact factory for the optional NIST-Traceable Calibration Certifications.

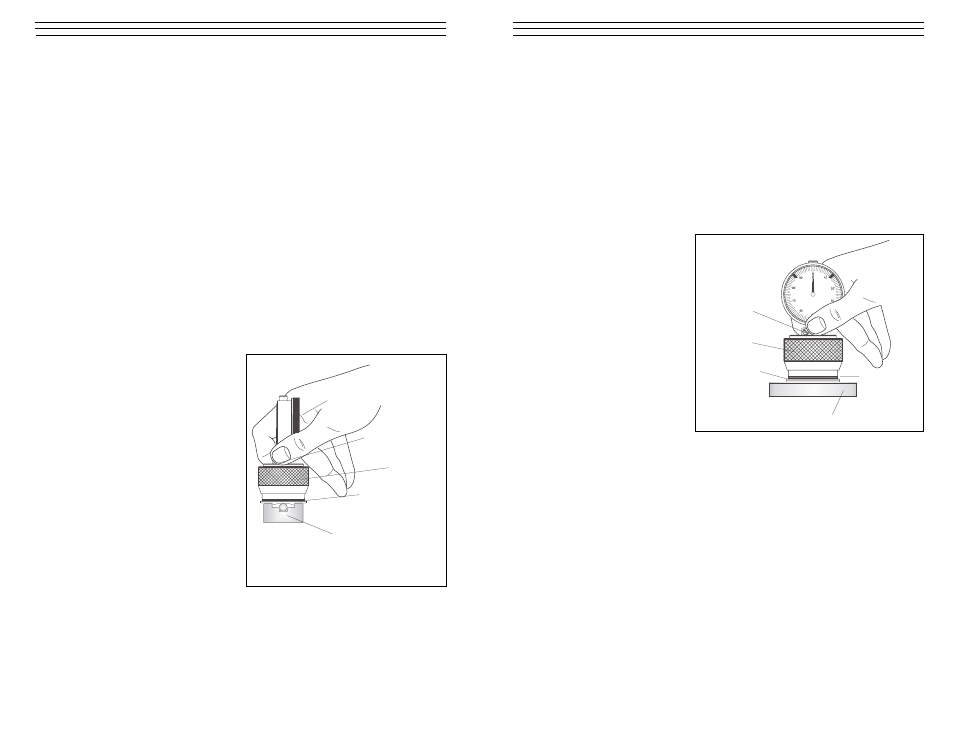

1. Press the Shore Durometer

down on a glass plate

(see Fig. 2). Do not move

the spring-loaded outer

ring.

2. The scale pointer should

make one full turn on the

scale, from zero to zero,

when you press down on

the instrument. If it does

not, contact Electromatic

for assistance.

NOTE:

Do not loosen the holding screws of the movement under any

circumstances. Loosening these screws may alter the calibration of the

instrument.

-5-

Scale

Glass plate

Spring-loaded

outer ring

Color marking

Holding screws

Fig. 2