Checkline HP-Textile-Durometer User Manual

Page 3

2.0 O

PERATING

P

ROCEDURES

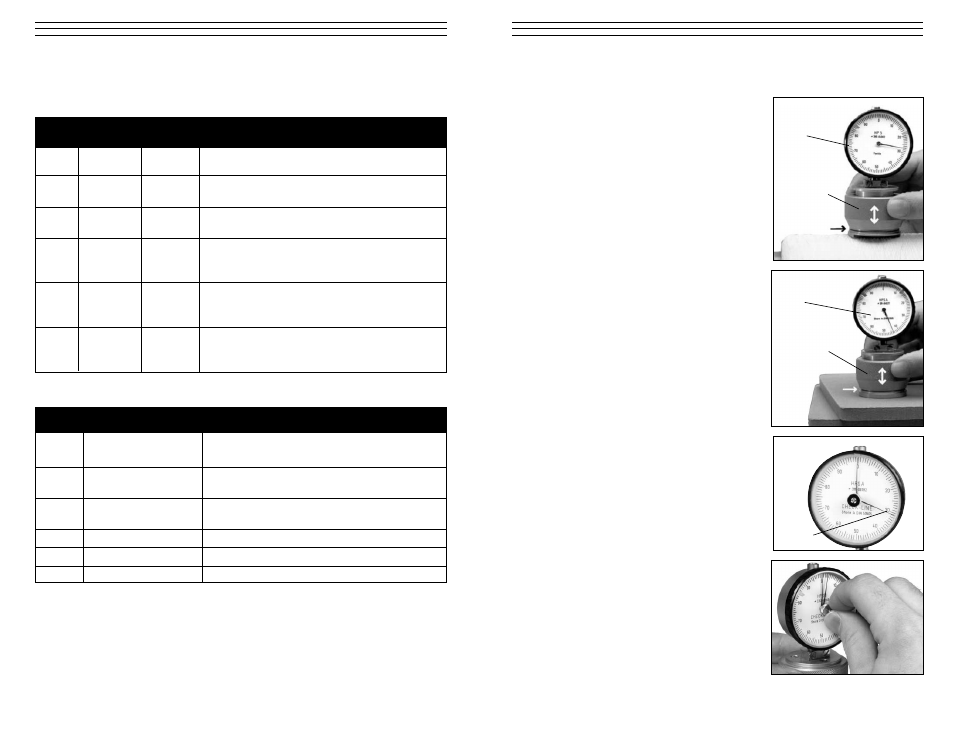

1. Place the instrument on the material

to be tested. The durometer must be

level, and the sensing pin must be

perpendicular to the material to be

tested.

Any angle other than perpendicular

(90°) mauy cause errors

2. Holding the knurled, spring-loaded

outer shell between fingers, press

downwards until the lower edge of

the shell meets the red line marked

on the housing. This ensures that

sufficient pressure is applied as

specified in the standard. It also

ensures that the same amount of

pressure is applied from measurment

to measurement, and when the

durometer is used by different

operators.

3. Record reading after approximately

2–3 seconds. Release pressure on

the outer shell and remove the

durometer from the test material.

2.1 Memory

Pointer

(optional)

The Memory Pointer moves with the

measurement pointer when a measure-

ment is taken. However, when pressure

on the outer shell is released, and the

measurement pointer returns to zero, the

Memory Pointer remains in position,

marking the last measurement.

To return the Memory Pointer to the

zero position prior to taking another

measurement, rotate the knurled knob

on the face of the instument counter-

clockwise until the pointer has been

reset. See figure at right.

Textile Durometer

Shore Durometer

Scale

Spring-Loaded

Outer Ring

Spring-Loaded

Outer Ring

Color Marking

Color Marking

Scale

-3-

-6-

Model

Indentor Decriptions

Typical Applications

HPSA

Truncated Cone

Soft rubber, elastomers, natural rubber products, etc.

35° Included Angle

HPSB

Conical

Rubber, elastomers, use when off the high end of the

35° Included Angle

“A” scale

HPSC

Truncated Cone

Medium hard rubber or plastics, use when off the low

35° Included Angle

end of the “D” scale

HPSD

Tapered pin 30°

Hard rubber, rigid thermoplastic products

HPSO

U-grooved 3/32 in.

Soft elastomers, textile fabrics

HPDO

Spherical 3/32 in.

Dense textile winding, medium printing rollers

Model Sensor

Ball Bottom

Typical

Diameter

Surface

Applications

HP-2.5

2.5

Ball

Closely wound bobbins of synthetic fibers

HP-5

5

Ball

Loosely wound bobbins of synthetic fibers

and closely wound natural fibers, yarns and threads

HP-10

10

Ball

Very loosely wound bobbins of thick yarns,m such as

carpet yarns

HP-2.5F

2.5

Flat

Same as Model HP-2.5 with a flat working face for

measuring warp beams, or for bobbin diameters with

over 400mm

HP-5F

5

Flat

Same as Model HP-5 with a flat working face for

measuring warp beams, or for bobbin diameters with

over 400mm

HP-10F

10

Flat

Same as Model HP-10 with a flat working face for

measuring warp beams, or for bobbin diameters with

over 400mm

4.0 A

VAILABLE

M

ODELS

Shore Durometers

Textile Durometers

Memory

Pointer