Operation, Specifications – Checkline TSA750 User Manual

Page 8

Series TS Force Measurement Test Stands

8

TSC1000 / TSC1000H

OPERATION

1. Mount the test stand to a firm, flat, and level working surface for maximum

safety and accuracy using four 5/16 screws (not included). Use the included

mounting hole drill template to accurately drill the holes (TSC1000, only).

Testing can take place without securing the test stand in such a manner,

however, it is strongly recommended that the stand be secured, especially

for large forces.

2. Install a force gauge onto the gauge plate with four thumb screws. Mark-10

force gauges mount directly to the stand without adapters.

3. Install any needed attachments, including grips, adapters, and other materi-

als necessary for your test sample. Make sure these

items are set up

in a secure and safe manner.

4. Zero out the force gauge, then begin the test by turning the hand wheel

clockwise for compression or counter-clockwise for tension.

Note: To maintain smooth functioning of the stand, avoid overloads and repeti-

tive shock loads.

Optional Equipment

Digital Travel Display Kit – for accurate position indication

This position indicator covers 6” of travel per setting with a 5-digit display

(0.0005” resolution) and a computer interface for automated data collection. It

may be easily installed by the user.

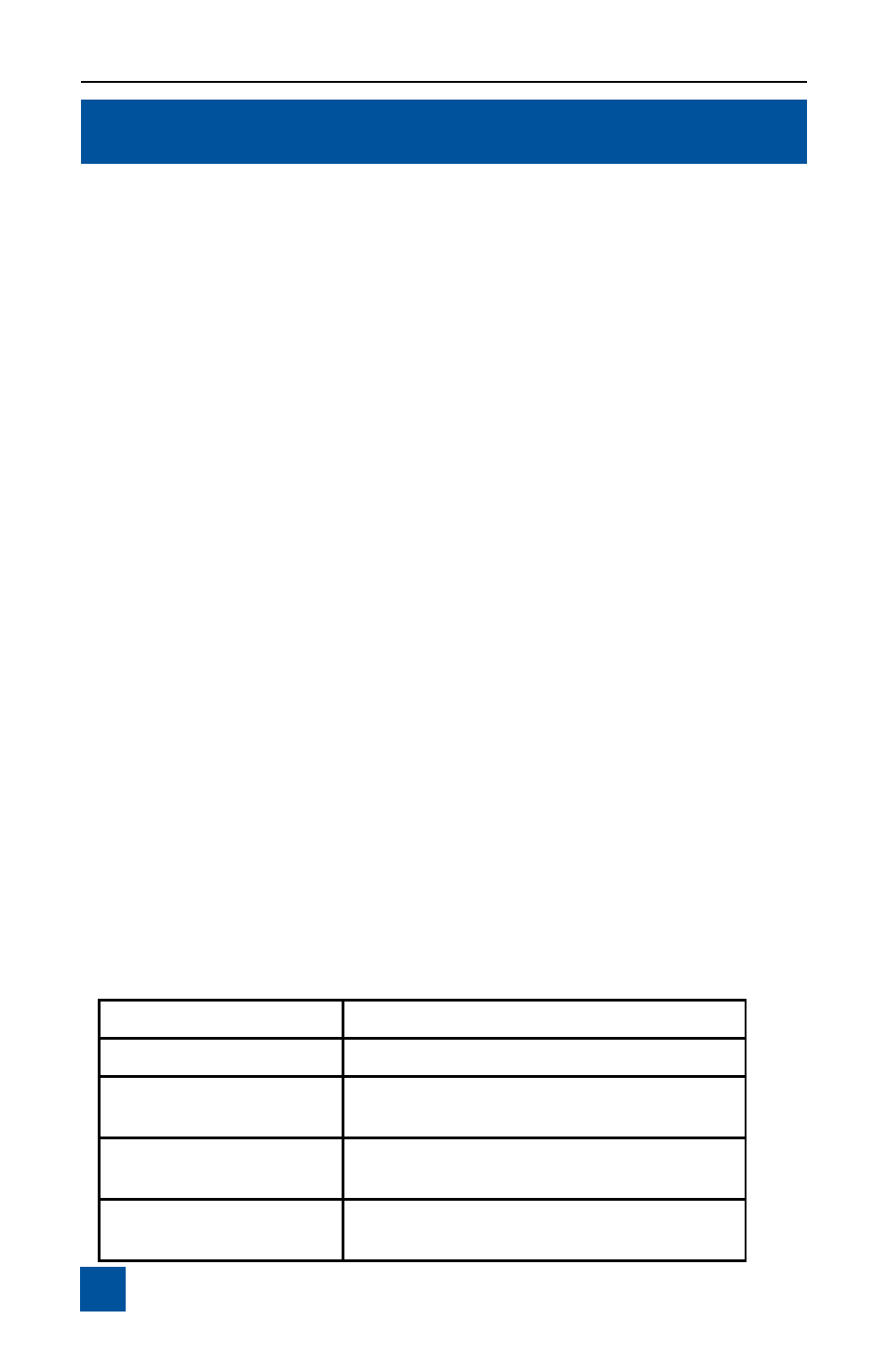

SPECIFICATIONS

Load capacity

1000 lb [5000 N]

Maximum travel

3.5” [88.9 mm]

Loading method / rate

Handwheel

0.1” [2.54 mm] per rev.

Weight (test stand, only)

TSC1000: 25 lb [9.0 kg],

TSC1000H: 20 lb [11.3 kg]

Digital travel display

(optional)

Resolution: 0.0005” [0.01 mm]