California Faucets Thermostatic Cartridge User Manual

Page 4

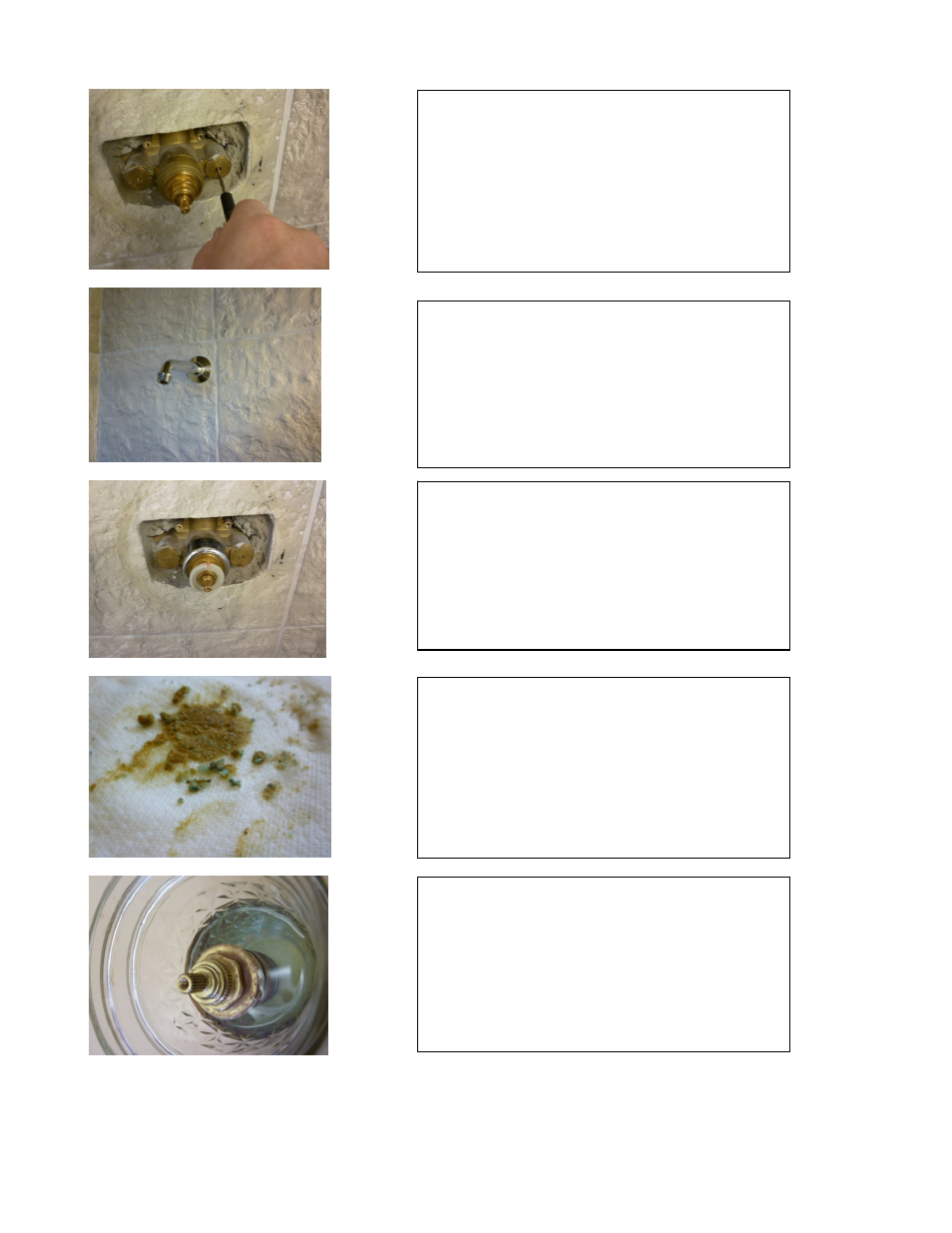

Carefully open both the hot and cold service

stops on the valve body using a small number one

(electrician type screwdriver). Do not rotate the

slotted head of the service stop screw beyond the

flat face of the hexagonal service stop housing.

Remove the shower arm and apply new Teflon

tape or thread sealant to all threads to ensure a

watertight connection to prevent a leak behind

the wall. Apply Silicone sealant or equivalent to

backside of shower arm and secure shower arm

to wall. Shower arm outlet should be downward.

Refer to installation instructions for Thermostatic

valve TH‐150 / TH‐175 for temperature

calibration and trim installation.

Here are examples of calcium build up, debris and

sediment that can cause a cartridge to become

stuck in a thermostatic valve body.

If hard water is present, the cartridge should be

removed and serviced every 1 or 2 years.

Annual service of the cartridge is as follows:

Soak cartridge in 100% undiluted white vinegar

for 2‐6 hours or until all calcium build up is

dissolved. Use old toothbrush to remove

deposits or debris on stainless steel screens.

Avoid excessive pressure on screens as this may

cause damage.

www.calfaucets.com 5271 Argosy Ave. Huntington Beach, CA 92649 800-822-8855