Finished wall, Maintenance – California Faucets Pressure Balance Valve User Manual

Page 3

PB-R_ii_110106.doc

Pg

3

3

4

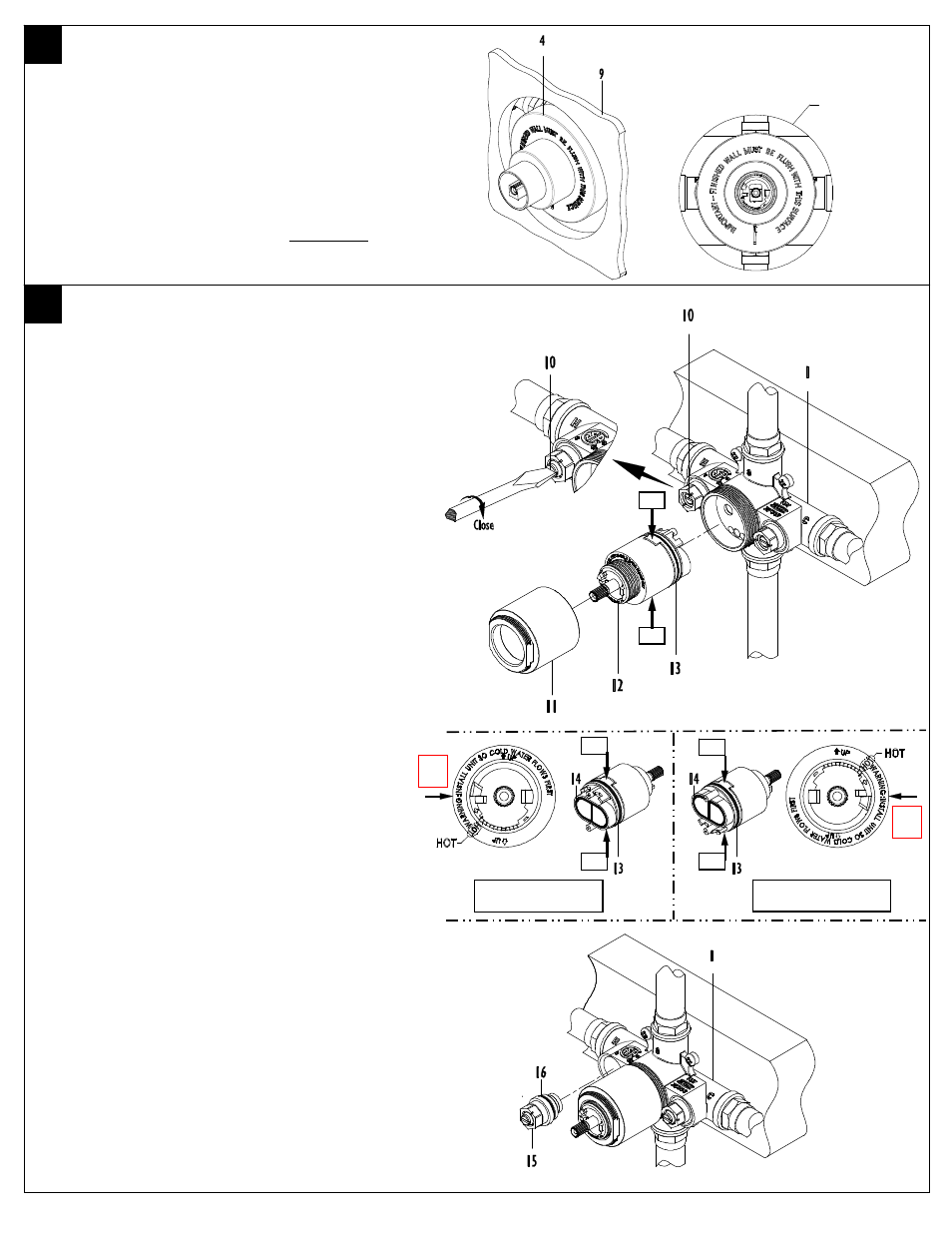

FINISHED WALL

• VALVE (1) shall be located in framed wall so that

FINISHED WALL (9) is FLUSH with surface of

MUDGUARD (4)

• The Maximum GAP between FINISHED WALL (9)

and MUDGUARD (4) should be no more than

1

⁄

4

” to

allow for proper trim coverage

• These finished wall requirements are necessary for

proper fit of trim as described in TO-PBL-XX ½”

Pressure Balance Trim Installation Instructions

MAINTENANCE

Pressure Balance Cartridge Service

• Shut off water supply to pressure balance cartridge

by turning hot & cold SERVICE STOP SCREW (10)

clockwise (inward) until screw stops

• Remove CARTRIDGE NUT (11) from BODY (1)

• Carefully remove CARTRIDGE (12) from BODY (1)

by holding CARTRIDGE (12) as close to BODY (1)

as possible and wiggle back and forth until

CARTRIDGE (12) comes out

IMPORTANT: To prevent accidental disassembly of cartridge during

removal, place finger and thumb on tabs of CARTRIDGE (12) as shown

• To determine if cartridge is functioning properly

shake cartridge from side to side, the internal piston

should make a clicking sound; if no sound perform

the following: Soak cartridge in white vinegar for at

least 8 hours to remove scale and debris; if still no

clicking sound is heard replace cartridge

IMPORTANT: Prior to installing CARTRIDGE (12), apply a thin film

of non-petroleum based grease onto O-RING (13)

• Tighten CARTRIDGE NUT (11) to 150 in-lbs

• Open hot & cold SERVICE STOP SCREW (10)

counter-clockwise (outward) until screw stops

Reversed COLD and HOT Inlets

• Perform above steps to remove CARTRIDGE (12)

from BODY (1), with CARTRIDGE (12) removed

rotate cartridge 180° and slide back into BODY (1)

CAUTION: When inserting CARTRIDGE (12) be certain that top

and bottom pins align into holes on BODY (1)

Check Valve Service

• Shut off water supply to valve inlets at main or valve

upstream from BODY (1)

• Remove CHECK VALVE (15) from BODY (1)

• Rinse CHECK VALVE (15) under running water

• Prior to installing CHECK VALVE (15) into BODY

(1), apply a thin film of non-petroleum based

grease onto O-RING (16)

• Tighten CHECK VALVE (15) to 150 in-lbs

ø

5” Max.

Diameter

Hot

Inlet

Hot

Inlet

Position of Cartridge

(factory assembled)

Position of Cartridge

for reverse connection

Tab

Tab

Tab

Tab

Tab

Tab