California Faucets Pressure Balance Valve User Manual

Page 2

PB-R_ii_110106.doc

Pg

2

1

2

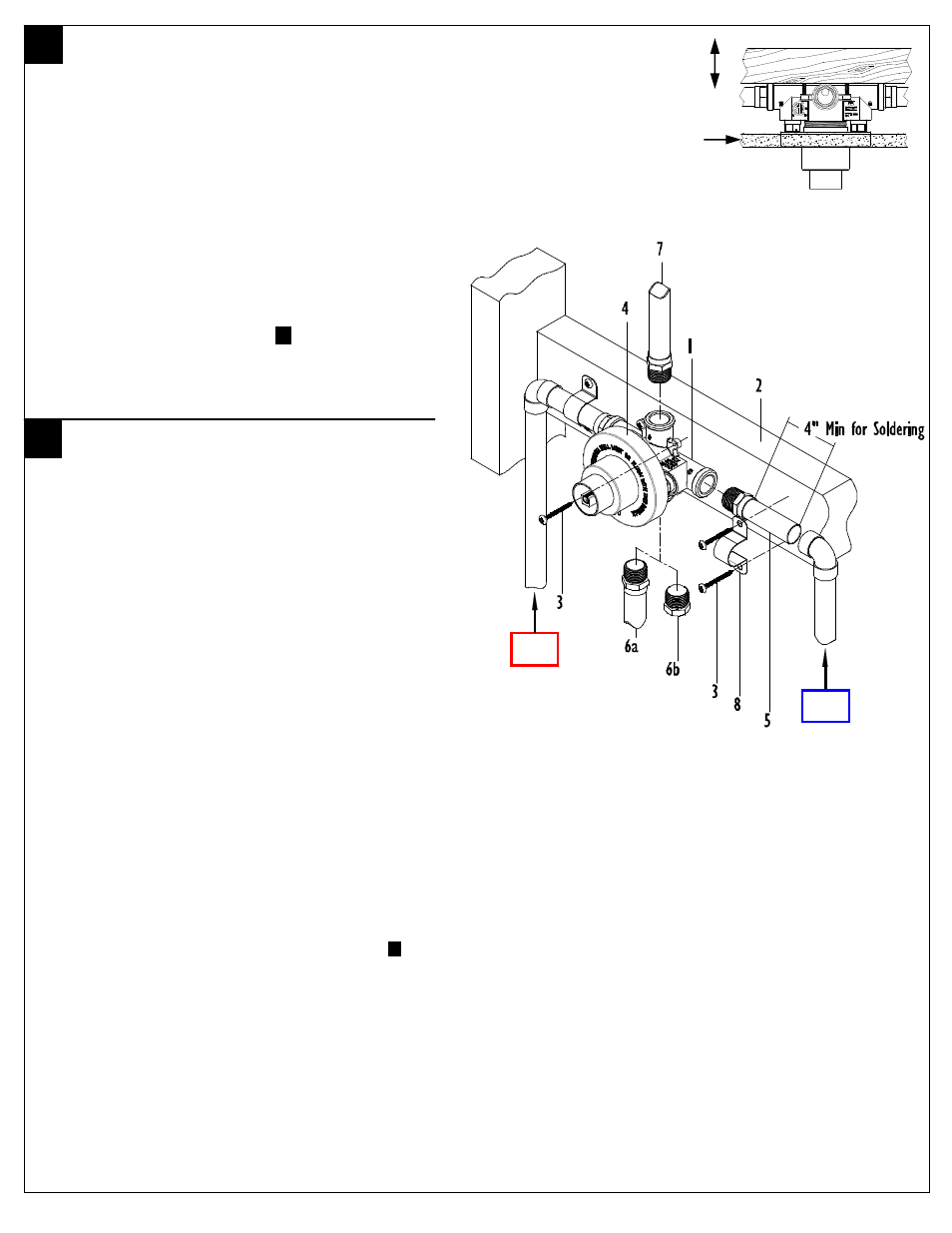

INSTALLING VALVE TO FRAME

• Determine the desired location for the valve,

construct suitable stud, and support framing

• Attach VALVE (1) to CROSS SUPPORT (2) by using

SCREWS (3) (not supplied) as shown

• The valve should be level in HORIZONTAL,

VERTICAL and PARALLEL to wall

• Placement of VALVE (1) and CROSS SUPPORT (2)

within the wall shall be determined by the MIN/MAX

limits shown on MUDGUARD (4)

• For complete detailed VALVE (1) dimensions and

recommended placement see .

5

. ROUGH-IN

DIMENSIONS

WATER

CONNECTIONS

• Pre-assemble FITTINGS (5) prior to attaching to

VALVE (1)

• Attach “C” INLET to COLD SUPPLY and “H”

INLET to HOT SUPPLY. All soldering of

FITTINGS (5) shall be performed a minimum

of 4” away from VALVE (1)

• Attach TUB PIPE (6a) to “T” OUTLET. Do not

use PEX or CPVC CTS piping from valve to

tub spout, as the reduced ID will result in too

much back pressure for valve to function

properly

• If valve is installed for SHOWER ONLY

configuration, attach PLUG (6b) to “T” OUTLET

• Attach SHOWER PIPE (7) to “S” OUTLET

• For additional support, use PIPE CLAMP (8) and

SCREW (3) (not supplied) at all attached pipe

connections

IMPORTANT: Flush supply lines prior to installation to prevent

damage and malfunction of pressure balance cartridge

IMPORTANT: If Cold and Hot supplies are not easily attachable to

desired inlet ports or for “Back-to-Back” installations, see .

4

.

MAINTENANCE

CAUTION: This valve contains plastic and rubber components. Do

not sweat or braze directly to the valve body. Do not apply excessive

heat to the valve body when you make solder connections. Do not apply

flux or acids directly to the valve, as damage to the seals, plastic

components, and trim finish may result

CAUTION: Inlet and outlet threaded joint connections should be

made with plumbers PTFE tape or liquid sealant. Oil-based, non-setting

compounds should not be used

Finished

Wall

HOT

SUPPLY

COLD

SUPPLY