BUCHI Syncor Polyvap User Manual

Page 32

Syncore

®

Accessories

30

version E

Function test

Tightness

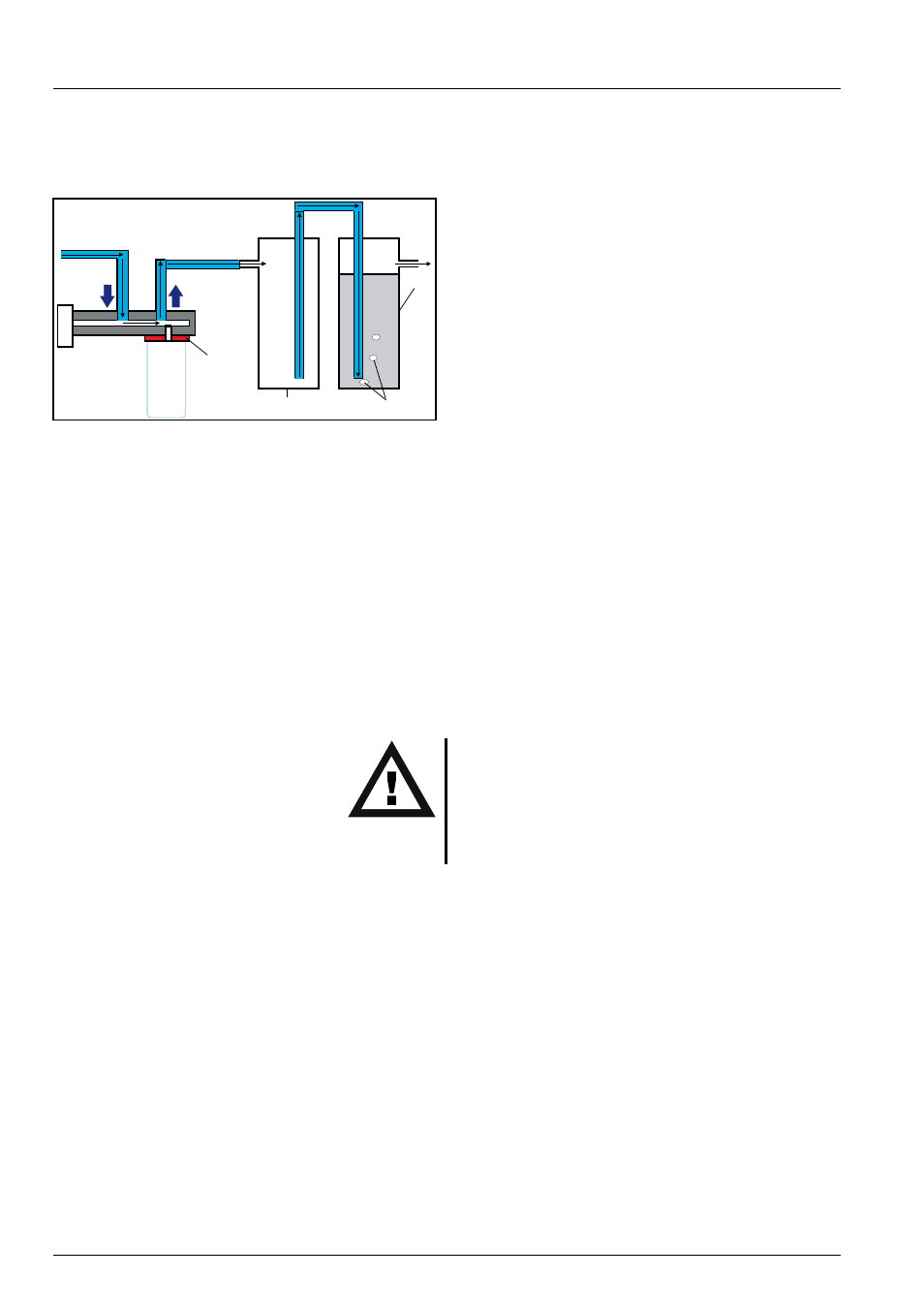

Tightness is tested at slight gas excess pressure.

To do so, the vacuum connection must be sealed with the

SVL22 lid.

The inert gas cover (or the inert gas module in connection

with a vacuum cover) is placed onto the 24 test tubes in rack

R-24. The inert gas cover is fastened to the test tubes using

the two tightening nuts (safety screws). Gas is supplied via

a valve in a controlled manner.

The gas discharge takes place via a tube, connected with

a gas wash bottle a or a bubble counter. A slight counter

pressure forms in the gas wash bottle or bubble counter

via water b or an other liquid. The inert gas connection is

to be completely sealed by tightening the tightening screws

via the individual sealing discs c of the test tubes, visible

via gas bubble formation d at the exit in bubble counter

or gas wash bottle.

In order to prevent backflushing of the sealing liquid, con-

nect the second gas scrubbing bottle as depicted in the

figure 40.

If no tightness is achieved when the tightening nuts are

moderately tightened, the test tubes used are to be checked

for unevenness, if necessary, individual test tubes, sealing

rings or sealing washers are to be replaced and the function

test repeated.

If the problem still persists, you should notify the supplier.

Figure 38: Gas flow and bubble counter

a

b

c

d

e

Function,putting into operation, operation and maintenace