BUCHI Syncor Polyvap User Manual

Page 25

Syncore

®

Accessories

version E

23

To ensure a quick warming of the vacuum connection, the

vortex drive should not be switched ON. A flashing in the

display „Actual“ indicates that the heater for the vacuum

connection is ON. This display keeps flashing until the set-

point temperature for the vacuum connection has been

reached. As soon as the „Start“ button is activated, the

display stays lit with a constant light.

Handling (General)

The vacuum connection consists of one basic part made of

coated aluminum, plus sealing discs, sealing rings, sealing

nipples, and a glass plate. The aluminum plate has a coating

of PFA. that is absolutely resistant to chemicals.

This chemically resistant coating must not become dama-

ged due to the contact with hard or pointed objects. If

this protective coating becomes damaged, the aluminum

will be attacked by solvents and chemicals. All vacuum

connections must always be stored on a soft base.

The sealing discs seal the individual sample tubes off vacu-

um-tight. Damaged or fouled sealing discs can be replaced

easily. Before putting the vacuum connection into use,

check that the sealing discs are clean and intact.

The sealing discs must not be handled with sharp or poin-

ted objects. It is not permissible to use any sample tubes

that have sharp edges that could cause damage to the

sealing discs.

Replacement of sealing discs

(R-4, R-6, R-12, R-24, R-96)

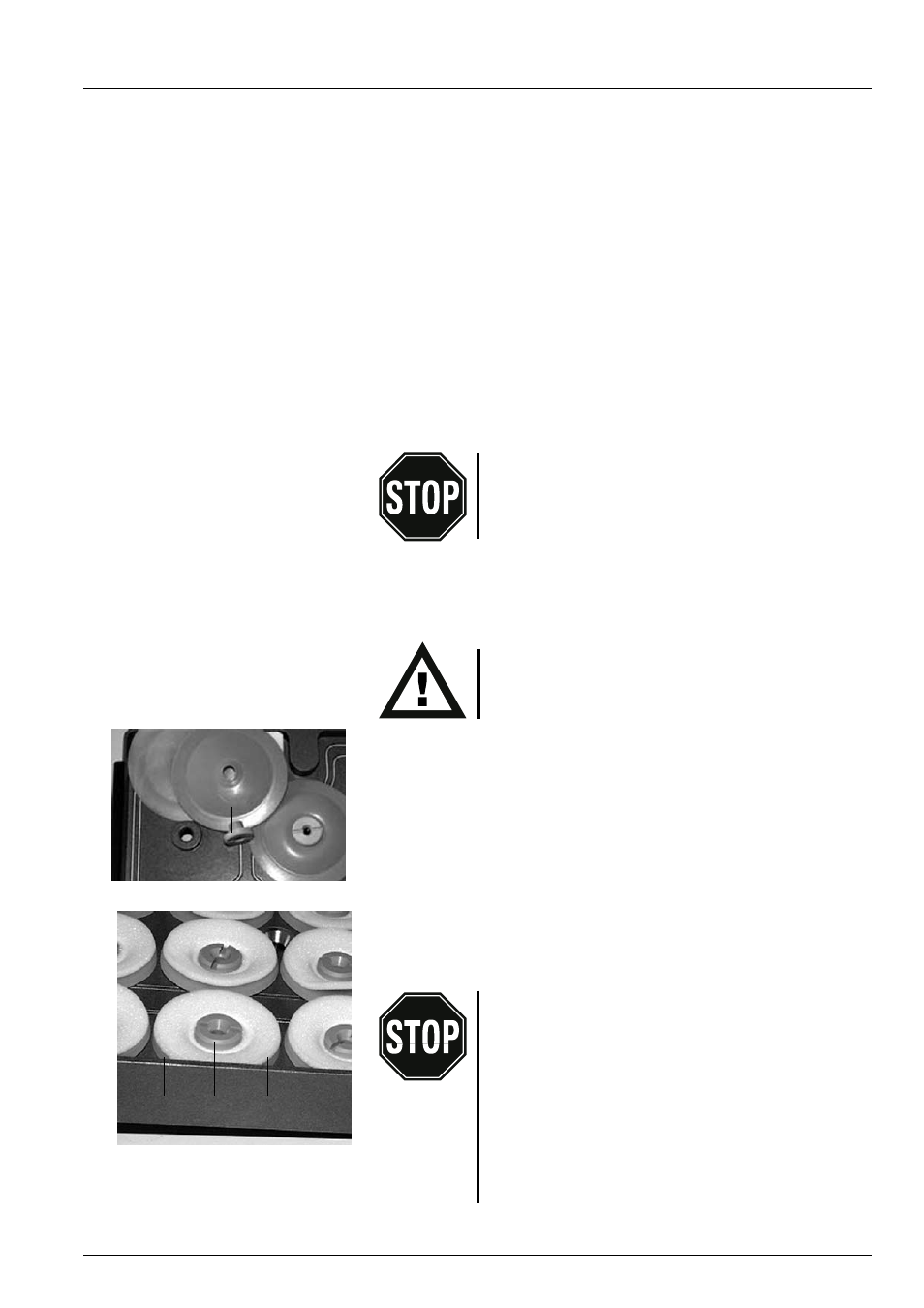

The sealing discs a can easily be replaced using a broad

screwdriver.

To do this, carefully unscrew the screw caps b made of

PEEK from the vacuum plate. The sealing discs c can

now be removed. If necessary, the silicone shims under

the vacuum connections can likewise be replaced after the

new sealing discs have been put in place, carefully screw

the screw caps of PEEK back in. Screw the screw caps

in carefully.

To avoid damaging the screw caps and the threads for

them in the vacuum connection, the screw caps must be

set down straight on the thread when screwing them in.

The force required to screw the screw caps in is approxi-

mately the same for all caps.

Whenever the screw clamps jam while being screwed in,

stop.

Screw the screw caps back out and screw them in again.

Whenever the sealing discs have been replaced, recheck

the vacuum connection for leaks.

Figure 26: Sealing discs: Fastening to the vacuum connection

Figure 25: Sealing discs: Fastening to the vacuum connection

a

b

c

a

b

c

3 Function,putting into operation, operation and maintenace